Cleaning the server

Preparation for use and operation

A26361-K646-Z102-1-7619

31

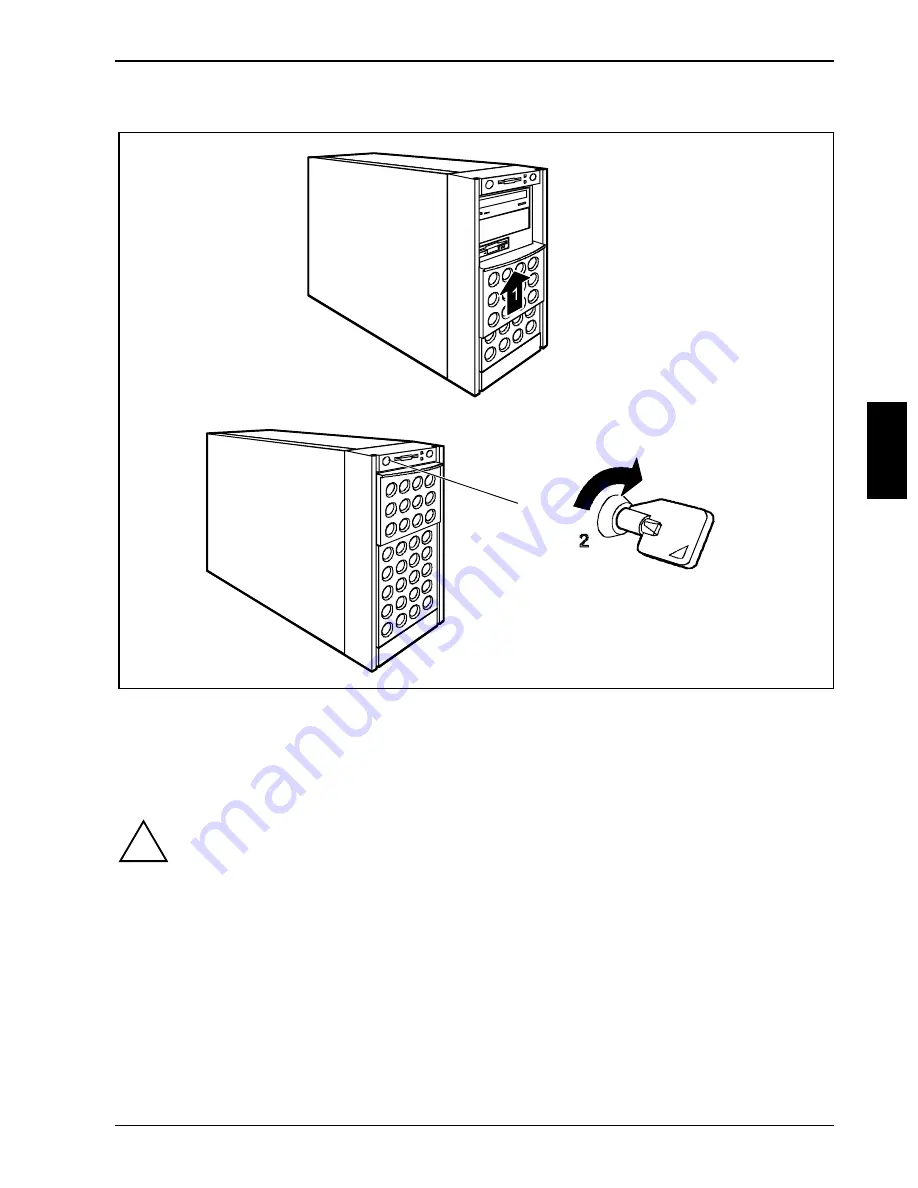

Locking the server

Ê

Slide the drive cover upwards (1).

Ê

Lock the server (2).

4.6

Cleaning the server

!

Switch the server off and pull the power plug out of the grounded-contact power socket.

Do not clean any interior parts yourself, leave this job to a service technician.

Do not use any cleaning agents that contain abrasives or may corrode plastic.

Ensure that no liquid enters the system.

Ensure that the ventilation areas of the server and the monitor are free.

Wipe the server and monitor casing with a dry cloth. If particularly dirty, use a cloth which has been

moistened in mild domestic detergent and then carefully wrung out.

Use disinfectant wipes to clean the keyboard and the mouse.