12

ECNO: 622

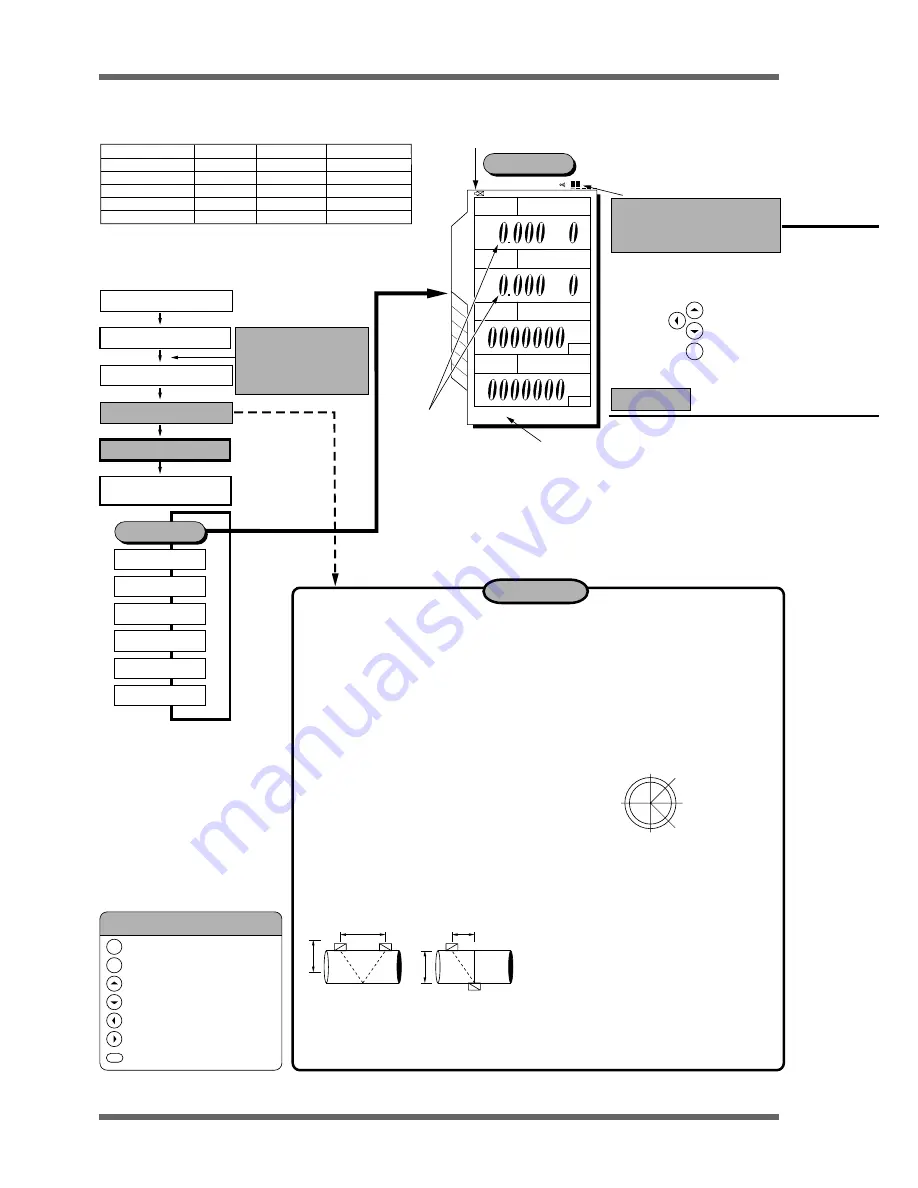

6. OPERATION

6.2 Preparation Prior to Measurement (Zero Adjustment, etc.)

Detector selection standard

Power ON

ENT

x10

x10

M3/h

m/s

ml

ml

99-05-11 11:49

×

1

×

2

×

4

×

8

Status display

x10

0

= 0

x10

1

=10

x10

2

=100

Example)

1.200

x10

2

corresponds to l.2 x 100 = 120m /h.

ENT

ESC

: ENTRY key (data registration)

: ESCAPE key (setting suspension)

: Cursor up-shift (set value feed)

: Cursor down-shift (set value return)

: Cursor left-shift (scale change)

: Cursor right-shift (scale change)

: Display screen printout (hard copy)

Description of key symbols

45

°

45

°

D

D

1) Straight piping greater than 10D must exist

on the upstream side and greater than 5D

on the downstream side.

2) Elements (pump, valve, etc) on the

upstream side must be greater than 30D

away to prevent disturbances

3) The piping must be filled with fluid free from

air bubbles and foreign objects.

Important!

Method of mounting for small sensor

(standard) and small diameter

sensors

(refer to Page 7 of this manual)

Selection of detector mounting

position

Selection of mounting method

r

o

t

c

e

t

e

D

e

p

y

T

)

m

m

(

r

e

t

e

m

a

i

d

e

d

i

s

n

I

(

°

C

e

g

n

a

r

e

r

u

t

a

r

e

p

m

e

T

)

r

o

s

n

e

s

r

e

t

e

m

a

i

d

ll

a

m

S

2

2

D

L

F

0

0

1

o

t

3

1

0

0

1

o

t

0

4

–

–

–

–

–

0

0

1

o

t

0

4

0

8

o

t

0

4

0

8

o

t

0

4

0

0

2

o

t

0

4

r

o

s

n

e

s

)

d

r

a

d

n

a

t

s

(

ll

a

m

S

2

1

D

L

F

0

0

4

o

t

0

5

r

o

s

n

e

s

e

g

r

a

L

1

5

D

L

F

0

0

0

6

o

t

0

0

2

0

0

2

1

o

t

0

0

2

r

o

s

n

e

s

e

r

u

t

a

r

e

p

m

e

t

-

h

g

i

H

2

3

D

L

F

0

0

4

o

t

0

5

FLD41

Middle sensor

* Straight piping greater than 10D must exist on the upstream side and greater than

5D on the downstream side.

* Elements (pump, valve, etc) on the upstream side must be greater than 30D away

to prevent disturbances.

When the power is ON, the

language select screen is

displayed. Select the

language to be used and

then press the ENT key.

Piping specification input

Sensor mounting

Measurement start

Measurement end

/Power OFF

Measurement

Site setup

Data logger

System setup

Printer

Analog

System check

Measurement

(Measurement cycle: Once/sec)

Indicator (receiving wave strength)

More than 2 indicators for standard

measurement. When one or no indicator

is working, the transmission voltage

should be raised.

Zero Adjustment

L = About D

L = About D/2

V method

Z method

L: Mounting size

Treatment of detector mounting side

•

Using thinner and sand-paper, remove the

pitches, rust and uneven surface of the detector

mounting piping over the entire mounting area

of (L) + 200mm wide.

•

When the piping exterior is wrapped with jute,

remove the jute and then perform the above

treatment.

•

Horizontal piping should be mounted within

±

45

°

from the horizon.

•

Vertical piping can be mounted at any external

position.

• Insufficient mounting space (about 1/2 of the size of

the V method)

Small diameter sensor and small type (standard)

sensor should be mounted by the V method.

In the following cases, the Z method should be

used for mounting.

• Piping with mortar lining

• Piping is old and presumed to have a deposit of a thick

layer of scales inside the piping.

1) Loosen the lock nut. After setting to the

mounting position, tighten the lock nut.

2) Coat the sensor transmission side with a

sufficient amount of silicone grease.

3) Attach both ends (saddle) to the piping

using a cloth belt.

4) Make sure that the sensor is mounted in

parallel with the piping and that the

mounting position is correct. Then, turn the

element holder clockwise until the sensor is

firmly fitted to the piping (clockwise;

element moves down, anti-clockwise;

element moves up).

3

RESET

STOP

RESET

STOP

FLOW RATE

UNIT:

VELOCITY

UNIT:

+TOTAL

UNIT:

–TOTAL

UNIT:

MEASURE

NORMAL

Battery alarm

(1)

(3)

(4)

(2)