PID SET UP WITH FRENIC Eco series inverter.

1

PID SET UP WITH FRENIC Eco series inverter.

1. Introduction.

This document describes briefly how to set up the FRENIC Eco series inverter to

implement a PID control, for example, a pressure control with a pump, where the

pump is moved by a motor controlled by a FRENIC Eco inverter.

2. Preparation.

Before setting up a PID controller few items have to be checked. As an example we

will describe a set up for controlling pressure.

•

Is the sensor capable of sensing the expected range?

When we want to control the pressure in a system to 2 Bar, the sensor must

be capable of measuring more. Preferably 1.5 times more, i.e. 3 Bar.

•

Does it have an output signal that can be connected directly to the FRENIC

Eco input?

FRENIC Eco has inputs for 0-10 V and 4-20 mA signals.

3. PID Basics.

3.1 PID Basic Concept.

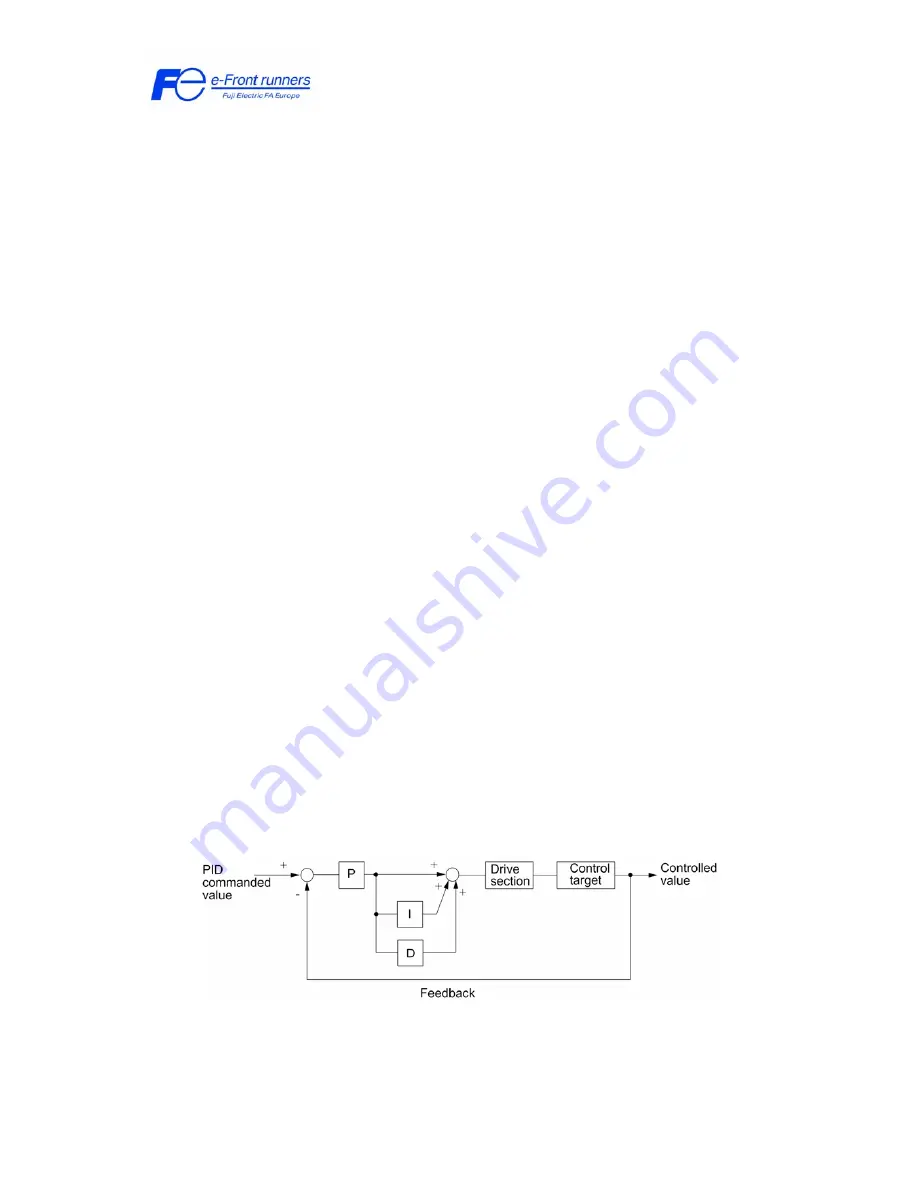

A PID regulator is a control structure that will try to control a certain magnitude

(pressure, flow rate, temperature, ...) to a desired value, which is called

PID

command

(or set-point) value. To do so this structure needs information of the actual

status of the system by means of the proper measurement device (pressure, flow or

temperature sensor). This signal is called the

PID Feedback

. This control structure

normally has three control actions: Proportional (P), Integral (I) and Derivative (D)

that have to be tuned according to the real system.

Figure 1. PID control structure diagram.

What happens in this picture?