SPEED CONTROL SCHEMATIC DIAGRAMS: (cont.)

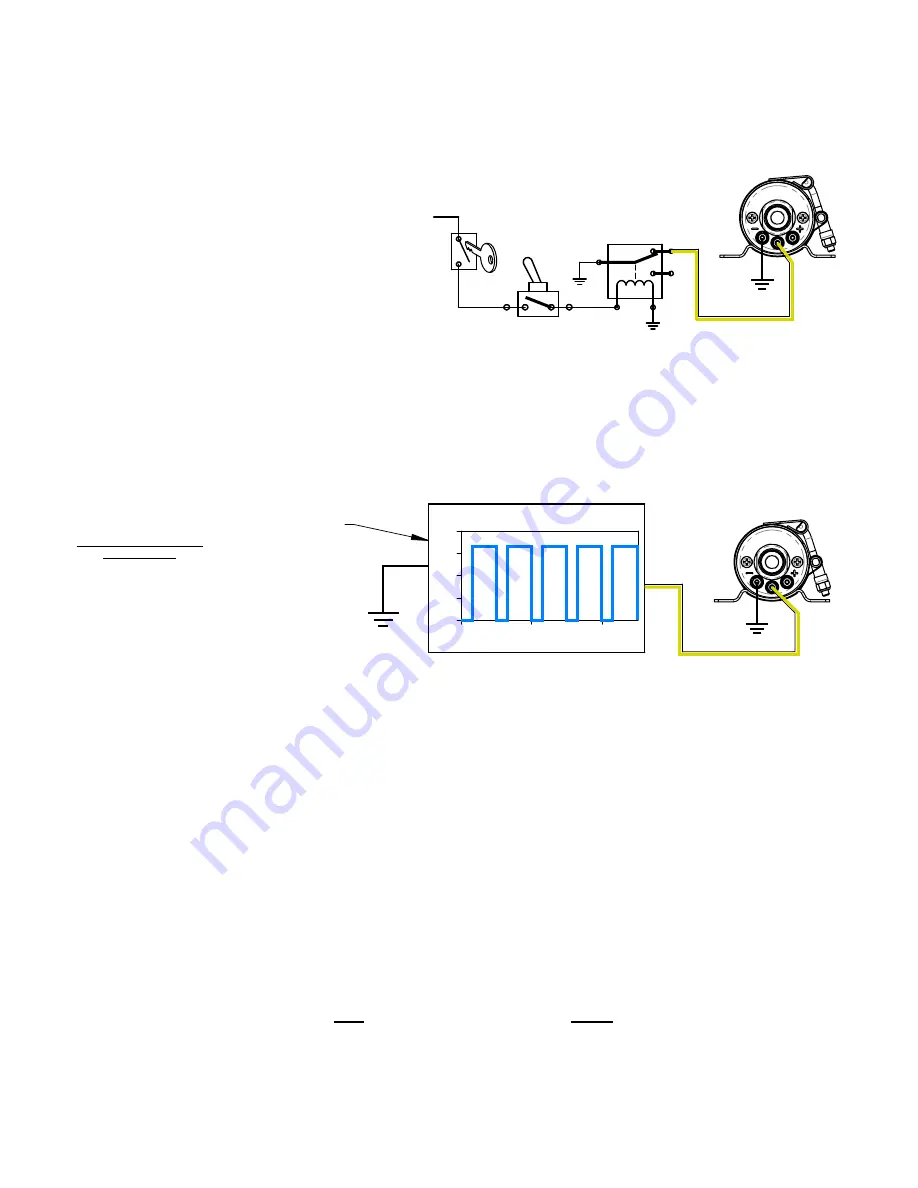

Example 4: Switch to Power Speed Changing

When the switching action is in reverse to what can be used as shown Example 3, such as some pressure

switches, the action can be reversed using

a Single Pole Dual Throw (SPDT) relay as

shown to the right. Current draw through

this circuit is extremely low (much less than

1 amp), so a very low current rating for this

relay and switch can be used. Use the

diagram to the right as a guide to properly

wire this example. Reduced speed is

recommended during long periods of low

engine fuel demand conditions to avoid fuel

system heat build-up.

Example 5: Variable Speed

Devices such as an aftermarket ECM can create a pulsed signal (“pulling” voltage to ground at a given

frequency). This signal has a characteristic of dwell time, which is a ratio of on-time vs. off-time (in other words,

the amount of time the signal is “high” vs. “low”). This difference in dwell time percentage will enable the fuel

pump to operate at various speeds or flow rate. A graph demonstrating an example signal created by such a

device is shown below. The example signal is at 66% duty cycle, whereas the amount time that the signal is

above 1.65V voltage is about twice the amount of time at zero volts. When duty cycle is between 5%-20%, the

fuel pump is turned off. A duty cycle between 20%-90% will be variable speed between Minimum and Maximum

Speeds, while duty cycles of 90%-100% are at Full Speed. Frequency range is allowed between 100Hz and

5000Hz. “High” voltage may be as high as the vehicle’s voltage.

Refer to above Example 5, for use with the Fuelab Electronic Fuel Pressure Regulator, Models 52901 and

52902, that creates its own pulsed signal. These regulators automatically control the fuel pump, without the use

of switching means or other components such as described in examples 2 and 3. Refer to instructions for the

Electronic Regulator for proper wiring and installation.

Installation Steps:

1. Disconnect the ground terminal from battery and allow the vehicle’s engine and exhaust system to cool.

Relieve fuel system pressure per applicable service manual. Follow all Warnings, Cautions and Instructions

written on previous pages of these instructions.

2. Modify, remove, or replace other fuel system components as required per established build plan (reference

notes on previous pages and above).

3. Use the supplied brackets attached to the fuel pump, as a drilling template to mark holes for mounting bracket.

Choose a location that minimizes exposure to road hazards and debris, away from engine exhaust pipes, near

fuel tank or cell. Note position and plumbing requirements as stated earlier in these instructions.

4. Install the fuel fittings (not supplied). The threads used on these fuel ports are not tapered or pipe threads. Do

not use Teflon

thread tape or thread sealant on these threads, as this can cause leakage or introduce debris

into the fuel system. Fittings to be used with these style of ports require use of the enclosed -910 o-rings for

proper sealing. Use light oil to lubricate the o-rings just prior to installation. Install the O-rings onto the fuel

fitting first. Position the o-ring in the thread relief of the fitting. Thread fitting into fuel pump and tighten

between 5 and 15 ft

ꞏ

lbs of torque.

ALL

fuel line that is internal to tank

MUST

be fuel compatible both inside

and outside of the line. PTFE based fuel line is recommended for a long service life.

5. Upon installation of fuel tank or cell and installation of all other fuel system components, Inspect fuel system for

any contact of fuel lines or wires with other components that can cause chafing or rubbing. Secure all

components and fuel lines. Ensure that moving components of vehicle are clear.

6. Connect the vehicle’s battery. Perform initial priming: The fuel pump may require priming during initial

operation and for moment after depletion of fuel from fuel tank or cell. This action can be accomplished by

removing fuel line from fuel rail (downstream of fuel pump and filters), allowing the fuel line to empty fluid into

110020271-1, Rev E Sheet 4 of 6

AT REDUCED SPEED

SPDT RELAY

NO

C

SHOWN (OPEN).

NC

WITH SWITCH POSITION

(1+A Rating)

PUMP OPERATES

FROM

FUSED

SOURCE

2

4

-3

Input Signal

(shown right):

* Freq. = 1000Hz

Example Square Wave,

4

3

2

1

0

* 0 to 3.3 Volts

* Dwell Time = 66%

Voltage (v)

0

Electronic Device,

such as Aftermarket

Engine Control Unit

(Oscilloscope-like

displayshown,

representing incoming

speed control signal).

Time (sec X10 )