PA3200C

24

EN

Service, repairs and maintenance

For all service, repair and maintenance first

carry out the following:

1. Disconnect the power supply.

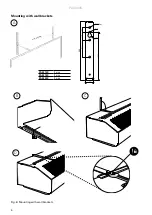

2. The front hatch is removed by removing

the screws on the top of the unit and then

detach the bent edge at the bottom. (Fig.3)

3. After the service, repair and maintenance

reattach the front hatch. Place the hatch

at the lower edge with the bent edge and

fasten on top with screws.

Note that when carrying out work where the

end is removed, the outlet grille also detaches.

Start-up (E)

When the unit is used for the first time or

after a long period of non-use, smoke or an

odour may result from dust or dirt which has

collected on the element. This is completely

normal and disappears after a short time.

Adjustment of the air curtain and airflow

The direction and speed of the airflow should

be adjusted considering the load on the

opening. Pressure forces affect the airstream

and force it inwards towards the premises

(when the premises are heated and the

outdoor air is cold).

The airstream should, therefore, be directed

outwards to withstand the load. Generally

speaking, the higher the load, the greater the

angle required.

Basic setting fan speed

The fan speed when the door is open is

set using the control. Note that the airflow

direction and the fan speed may need fine

adjustment depending on the loading of the

door.

Filter (W)

The water coil is protected against dirt and

blockage by an internal air filter which covers

the coil face. In environments where the filter

requires frequent cleaning, it is advisable to

use an external intake filter (see accessories

pages), which provides easier maintenance,

since the unit does not need to be opened.

When an external filter is used, the internal

filter is removed.

[kW]

[V]

[mm

2

]

0

230V~

1,5

PA3210CE08

8

400V3~

2,5

PA3215CE12

12

400V3~

4

PA3220CE16

16

400V3~

6

*) Dimensioning of external wiring shall comply

with applicable regulations and local deviations

may occur.

Type

Output

Voltage

Minimum

area*

Control

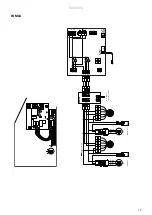

Connecting the water coil (W)

The installation must be carried out by an

authorised installer.

The water coil has copper tubes with

aluminium fins and is suitable for connection

to a closed water heating system. The heating

coil must not be connected to a mains

pressure water system or an open water

system.

Note that the unit shall be preceded by a

regulating valve, see Frico valve kit.

The water coil is connected on top of the unit

via steel pipes with DN20 (3/4’’) terminals,

external thread. Flexible hoses are available

as accessories, see accessories pages.

The connections to the heating coil must

be equipped with shut off valves to allow

trouble-free removal. The water coil is

equipped with a drain valve. A vent valve

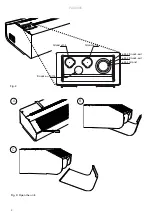

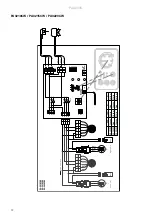

Unit with electrical heating

The electrical connection is made on the top

of the unit. See Fig.2. Control (230V~) and

power supply for heat (400V3~) should be

connected to a terminal block in the terminal

box. 2-metre and longer units require dual

power supplies.

The largest cable diameter for the terminal

block is 16 mm². The cable glands used must

meet the protection class requirements. In

the distribution board, it is to be indicated

that ”the air curtains can be supplied from

more than one connection”.

See wiring diagrams.

should be connected at a high point in the

pipe system. Air valves are not included.

NOTE: Care must be taken when

connecting the pipes. Use a pipe wrench or a

similar tool to grip the air curtain connections

to prevent straining of the pipes and

subsequent water leakage during connection

to the water supply pipe-work.

Summary of Contents for 19802

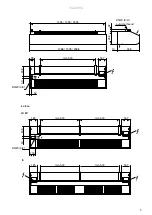

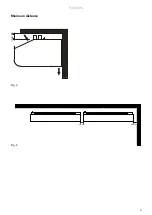

Page 5: ...PA3200C 5 Fig 4 Fig 5 Minimum distance 30 mm 60 mm min 60 ...

Page 22: ......