HOW AN ENGINE WORKS

HOW AN ENGINE WORKS

38

39

Basic Principles

To explain how a full-size car engine works, we’ll use a simplified version of a real engine -

our model engine in fact. You can switch on your finished model as you read this

explanation and it will help you to understand how a real engine works.

An engine crankshaft is described as such because it is a ‘cranked’ shaft – the shaft has

offset sections, to which the six piston/connecting rod assemblies are connected. In the

model, as the crankshaft turns (driven by the electric motor), the cranked sections move

around the centreline of the crankshaft, and convert the rotation to the reciprocating (up

and down) movement of the pistons. In a real engine, it is the movement of the pistons

(driven by the burning of fuel in the cylinders) that causes the crankshaft to rotate.

The engine’s crankshaft drives the transmission, which includes various different

components connected together whose job it is to drive the car’s wheels, making the

car move.

Now let’s look at how the engine works in more detail. We’ll look at just one cylinder of the

engine. A cylinder is the hollow cylinder inside the engine in which one piston moves up and

down. The piston has seals, called piston rings, around its edge, which aren’t shown on our

model and these seals stop gases passing round the sides of the piston. Our model has

six cylinders.

When you turn the engine to start the car, the starter (a powerful electric motor, powered by

the car’s battery) turns the crankshaft, moving the pistons up and down.

As a piston moves down from its highest position inside the cylinder (called ‘Top Dead

Centre’ or ‘TDC’), a mixture of fuel and air is sucked into the space inside the cylinder

above the piston. This is called the intake stroke.

The starter continues to turn the crankshaft and, as the piston moves back up towards the

top of its cylinder, the fuel/air mixture is compressed (squashed) in the space above the

piston. This is called the compression stroke.

As the piston reaches its highest point, a spark plug creates a spark above the piston and

this spark ignites the fuel/air mixture, causing a small controlled explosion above the piston.

The explosion pushes the piston downwards and this is called the power stroke.

Once the piston has reached its lowest point, it starts to move back up its cylinder, pushing

the burnt gases out through the top of the cylinder. This is called the exhaust stroke.

So, the engine has four strokes; intake, compression, power and exhaust, or ‘suck’,

‘squeeze’, ‘bang’ and ‘blow’ to make it simpler. These four strokes make up the

4-stoke cycle.

The fuel/air mixture flows into the space above the piston, called the combustion chamber.

The mixture flows in through a small hole which is opened and closed by the inlet valve.

The burnt gas flows out of the cylinder through another hole which is opened and closed by

the exhaust valve. The valves are normally held closed by springs, but as the engine turns the

valves are pushed open in the correct order by the rocker arms, which are moved by the

camshaft. The rocker arm pushes the valve down against its spring and, as the rocker moves

up, the spring pushes the valve closed.

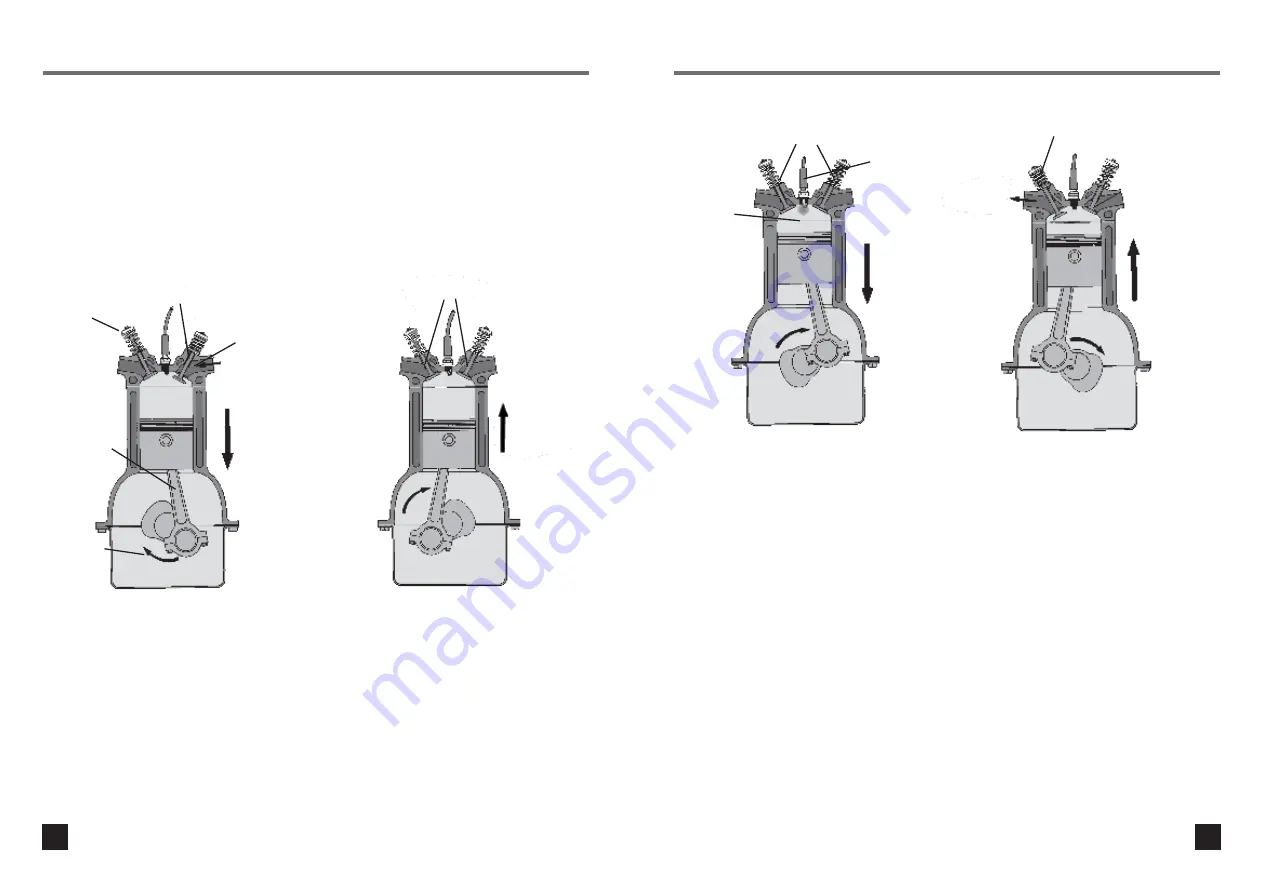

The 1st stroke (intake)

The piston starts off at the top of the

cylinder. The exhaust valve is closed and

the inlet valve is open. As the crankshaft

turns and the piston moves down inside the

cylinder, fuel/air mixture is sucked in

through the inlet valve. When the piston

reaches its lowest point inside the cylinder,

the cylinder is filled with fuel/air mixture and

the inlet valve closes. This is the end of the

intake stroke.

The 2nd stroke (Compression)

At the start of the compression stroke, the

piston is at its lowest point inside the

cylinder and the inlet and exhaust valves are

closed. The crankshaft continues turning

and the piston moves upwards. As the

piston moves upwards it squeezes

(compresses) the fuel/air mixture and this

increases the temperature of the mixture

very quickly. When the piston reaches its

highest point the mixture is fully compressed

and this is the end of the compression

stroke.

4-stroke cycle

Inlet valve open

Valves closed

Piston rises

compressing

fuel/air

mixture

Exhaust

valve

closed

Inlet port

Piston moves

down sucking

in fuel/air

mixture

Connecting

rod

Crankshaft

rotation

The 4th stroke (Exhaust)

As the piston starts to move up inside the

cylinder again, the exhaust valve opens to

allow the burnt (exhaust) gas to escape

from the cylinder and as the piston moves

up the cylinder it pushes the gas out

through the exhaust valve. As the piston

reaches the top of the cylinder the exhaust

valve closes, the exhaust stroke ends and

the 4-stroke cycle begins again with another

intake stroke.

The 3rd stroke (Power)

The very high pressure and temperature

inside the combustion chamber cause the

fuel/air mixture to break up into very fine

particles, like a mist. These are perfect

conditions for burning a gas. All that’s

needed to start the burning (or ‘combustion’ –

a kind of controlled explosion) is a spark. A

very high electrical voltage supplied to the

spark plug causes a spark to jump across the

gap at the end of the spark plug. This ignites

the fuel/air mixture and starts the combustion.

The force of the controlled explosion and the

expanding gases forces the piston

downwards, which pushes the crankshaft

round. During the power stroke, three things

happen to the fuel/air mixture – it ignites,

combusts (burns) and expands. The

expansion of the gas pushes the piston

down, which transfers power to the

crankshaft. When the piston reaches its

lowest point inside the cylinder this is the end

of the power stroke.

Valves closed

Piston forced

down by

expanding

gases

Exhaust valve open

Piston moves

up forcing

exhaust

gases out of

cylinder

Fuel / air

mixture

ignites

Summary of Contents for PE01

Page 5: ...PARTS LIST PARTS LIST 8 9...