3 INSTALLATION AND PREPARATION

3.1 Ambient temperature

Maximum: +40

º

C.

Should the temperature of the pumped liquid exceed

40

º

C, or in case of use at high altitude (higher than

1000 meters), the motor power reduces due to the

reduced density of air useful to cool the same. In some

cases, it may be necessary to replace the motor with

one with greater power.

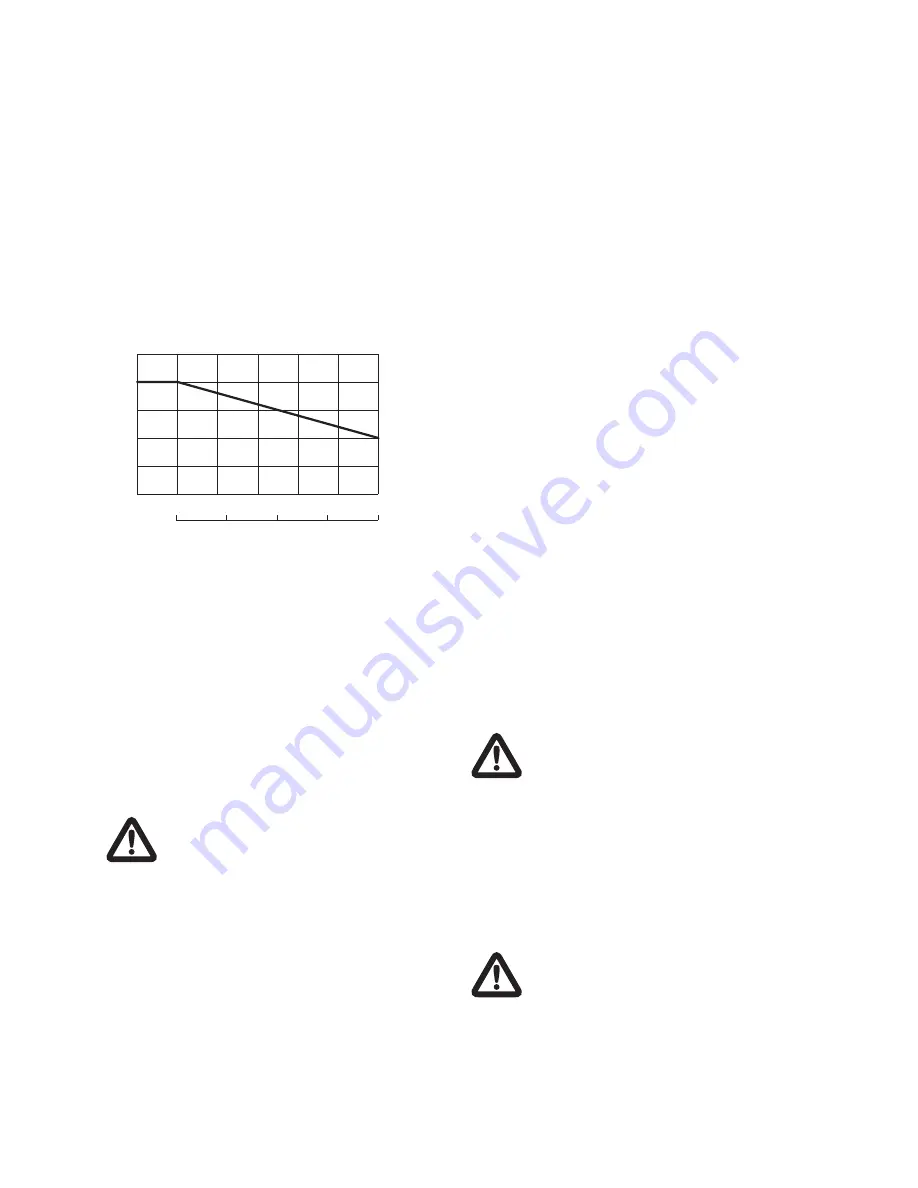

Here below there is an aproximate diagram

concerning the yield of the motors according to altitude

or temperature.

3.2 Minimum suction pressure

Check the characteristic curves of the pumps to assess

the NPSH factor and avoid cavitation problems (fig. 1

case B).

3.3 Maximum pressure during suction

It is important to keep the sum of the inlet and of the

outlet pressure, this latter against closed valve, always

lower than the maximum operation pressure allowed by

the pump (fig. 1 case A).

3.4 Minimum rate flow

The operation of the pump at a lower level than

the minimum rate flow allowed can cause excessive

overheating and damage the pump.

The pump must never operate against a

closed delivery valve.

3.5 Power supply data

See motor nameplate.

4 INSTALLATION

Legend figure 1:

1- Filter

2- Bottom valve

3- Gate valve

4- Pressure gauge

5- Check valve

6- Floating device

7- Anchorings for pipings

500

1000

1500

2000

2500

3000

3500

60

70

80

90

100

110

40

45

50

55

60

T °C

ambient

max

H m

altitude

max

P/Pn %

There can be two relevant application cases:

- Case shown in fig. 1.A: Pump under pressure, which

both from a tank as shown in figure and from civil

waterworks system, shall allow the plant to foresee a

protection against water lack (see fig. 1.6).

- Case shown in fig. 1.B: Pump in suction.

4.1 Assembly

Install the pump in an accessible place, protected

against frost and as close as possible to the water

suction point.

The pump must be tightly fastened to the basement by

means of bolts, for the measures of the holes and their

distance between centres, see the table on page 5.

To minimize the noise generated during the operation, it

is suggested to assemble the anti-vibration joints on the

tie rods fastening the base to the flooring.

Before proceeding to the final tightening of the pump,

make sure that it is in vertical position, otherwise adjust

the position with proper shims.

On the base of the pump it is indicated, by means of

arrows, the inlet and output direction of the pumped

fluid. On the lantern there are the arrows indicating the

motor rotation direction.

The pump can be assembled vertically or horizontally,

in any case it must not be placed vertically with motor

located in the lower part.

To avoid unnecessary stresses on the pump body,

place some support brackets (see fig. 1.7) in order to

support the incoming and outcoming pipe.

To avoid air blows affecting the pump operation, foresee

an inclination of the incoming pipes not lower than 2%.

Protect the pump against possible water hammers

by means of a check valve (bottom valve). Install a

shut-off valve upstream and downstream of the pump

in order to allow its insulation in case of maintenance

and disassembly.

4.2 Electric connections

The electric connection must be carried out

by qualified technicians in compliance with

the regulation in force in the countries of

installation of the pump.

Before replacing the cover of the terminal board and

removing / disassembling the pump, make sure power

supply has been disconnected.

The data concerning motor power supply are given on

the rating plate of the same. Before starting the motor,

check that electric power supply complies with the

features of the same.

For the connections, use electric cables complying with

local regulations.

When observed from above, standard 3VR,

5VR and 9VR pumps should rotate clockwise,

16VR should rotate counter-clockwise.

If necessary, the motor can be rotated on its axis to ease

the access to the same by maintenance technicians.

In this case, it is necessary to unscrew the screws

tightening the motor on the pump, remove the joint

covering safety carter and rotate the motor on its seat

paying attention not to remove the coupling joint.

2