2

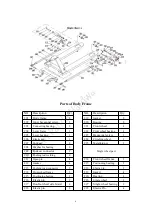

After finish operation, the control handle shall be pull back to middle position.

The three positions have been set prior to shipment. For any reason the positions have been

changed, following steps shall be followed for operation:

3.1 At middle position if control handle(119) pressurized and force forklift up, so hexagonal nut

(103) and the metalloid nut(105) on drop bolt(103) shall be adjusted clockwise until no more

raising even forklift pressurized and everything become normal.

3.2 At middle position if control handle pressurized and force forklift down,so hexagonal nut

(104) and metalloid nut(105) shall be adjusted counterclockwise until forklift no more going

down.

3.3 lf control handle (119) is at Lower Position but forklift doesn't go down, hexagonal nut (104)

shall be adjusted clockwise until forklift does down when finger-shaped control arm at Lower

Position. And check operation of handle welding prat at middle position (operation position)

following step 3.1 and 3.2 to ensure hexagonal nut(104) is at right position.

3.4 At Raise Position if control handle pressurized but forklift no raising,hexagonal nut (104)

shall be adjusted counterclockwise until forklift goes up. And check operation of forklift at Lower

and middle position following step 3.1, 3.2 and 3.3 to ensure hexagonal nut(104) is at right

position.

4.Warning

Frequent maintenance is requested for forklift.

4.1 0iling

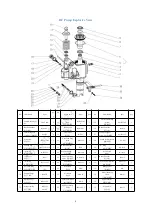

Check oil level every 3 months and oil can be hydraulic oil: ISOUG32, and its viscosity shall be

30cSt with total volume 0.41t.

4.2 Exhausting

For transport or upside down of pump, air maybe enters hydraulic oil and it will cause no going

up of forklift when control handle at Raise Position pressurized.

Below action may be followed to exhaust air: Pull the control handle (119) to Lower Position and

pull handle welding prat (113) to move it back and forth several times.

4.3 Daily Inspection & Maintenance

Daily inspection may reduce wear of forklift. Pay special attention to wheels and wheel shaft to

find whether thread or line wrapped. After transport, all cargo must be unloaded and make forklift

to the lowest position.

4.4 Lubricating .

Prior to shipment, all bearings and shafts have been applied with sustaining oil. Add oil to these

places on monthly basis or at through cleaning.

5.Guide to Safe Operation

5.1 Prior to operation of the forklift, operator shall thoroughly read the instruction manual and

cautions notes on forklift.

5.2 Normally pull control handle to middle position when dragging forklift. Not only is it easy

for moving handle welding prat but also it can reduce rebounding force the small pump core

applied to handle welding prat. Meanwhile, it can protect hydraulic sealing kits and piston

assembly to prolong life of forklift.

5.3 Personnel not familiar with the equipment or without training don't operate the forklift.