AB-8

1.

Remove the Drilling Machine

from the Tool Box (DMTB) and

lay it on a flat surface . Back the

Feedscrew (DMHF) out until

the end is flush with the Yoke

Assembly (DMY) .

2.

Select the diameter of Boring

Bar (DMBB) which will pass

through the Corporation Stop

when it is open . Attach the

Drill (DMD) to the Boring Bar

(DMBB) and lightly tighten with

the adjustable wrenches .

3.

Insert the Boring Bar (DMBB)

into the body of the machine

until the shoulder hits the stop .

Gently tighten the Packing

Bushing (DMPB) .

4.

Select the Adapter (DMA) that

matches the outlet threads on

the Corporation Stop . Attach

the Adapter (DMA) to the

bottom of the Drilling Machine .

5.

Mount the pipe saddle and

Corporation Stop on the water

main and tighten the saddle

straps . Mount the Drilling

Machine onto the Corporation

Stop .

Check to be sure the

Corporation Stop is fully

open.

6.

Carefully lower the Drill (DMD)

until it touches the water main .

Attach the Ratchet (DMRW) to

the top of the Boring Bar (DMBB) .

Raise the Yoke (DMY) until the

Feedscrew (DMHF) is centered over

the Boring Bar (DMBB) . Place a

few drops of oil on the point of the

Feedscrew (DMHF) and mate the

point with the center of the Boring

Bar (DMBB) . Open Chip Flushing

Port (if equipped) .

7.

Rotate the Ratchet (DMRW)

clockwise

only

while applying a

light

turn of the Feedscrew (DMHF) .

Make at least two (2) quarter

turns of the Ratchet (DMRW)

before applying more pressure

on the Feedscrew (DMHF) . Use

Feedscrew (DMHF) as follower

only and exert light pressure on the

Boring Bar (DMBB) . When drilling

PVC pipe use a steady continuous

cutting action and do

not

stop until

the cutter is completely through

the pipe . With PVC it is important

to continue cutting until the Shell

Cutter has penetrated the wall of

the water main and the Boring

Bar (DMBB) shoulder contacts the

bottom stop in the Adapter (DMA) .

8.

Slowly reverse the Feedscrew

(DMHF) and allow the Boring

Bar (DMBB) to slowly back out

until it hits the top stop in the

machine . If you are drilling into a

live/pressurized line, the Drilling

Machine will be under pressure . As

you back out the Boring Bar, place

the palm of you hand on the Ratchet

to prevent the Boring Bar from

snapping out of the main . Close

the Corporation Stop and release

the entrapped pressure before

removing the Drilling Machine from

the Corporation Stop .

IMPORTAnT – geneRAl MAInTenAnCe

1 . Clean the tools and lightly oil the boring bar (DMBB) and cutters before returning them to the tool box (DMTB) .

2 . When using the PVC shell cutter (DMSC), the assembly and operation is the same as using a drill (DMD) . For 3/4" PVC

taps, use the 11/16" shell cutter (DMSC-3) . For 1" PVC taps, use the 7/8" shell cutter (DMSC-4A) .

3 . Check the cutters regularly for sharpness . Sharp cutters will assure an easy tap . Professional sharpening is a good

investment because the cutting edge will have the proper angle, lip clearance, and chisel point to match the hardness of the pipe .

4 . When the day’s work is completed, always dismantle and replace the drilling machine in the tool box so nothing will be lost or

damaged .

Cutters will break easily if the machine assembly is dropped or mishandled

. Simple preventative maintenance

will make this device last for many years at a minimal cost per tap .

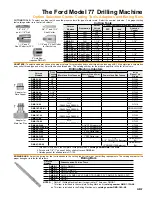

Ford Model 77 Operating Instructions

CAuTIOn: Always follow pipe manufacturer’s recommendations to protect from injury.

Summary of Contents for 77

Page 2: ...AB 2 ...