FLYBOX

Omnia57-80 RPM-MAP

-

Installation and User Manual,

Safety Instructions and Warning Booklet

Rev. 2.0

®

12

Electrical installation

PIN

I/O

Signal

1

I

+V Main supply, 10-30Vdc, with a proper

breaker, see note1

2

O

Vout for sensors, it delivers the same

voltage supplied on the Pin 1, short

circuit protected and limited to 500mA

3

O

5V out for sensor, short circuit protected

and limited to 350mA

12

I

GND main supply

13

O

Alarm Out, NPN 300 mA (not protected)

14

I

Ambient light sensor input

15

I

External switch

18

I

RPM L Input (2-20Vpp min 100uS)

19

I

RPM H Input (5-100Vpp min 100uS)

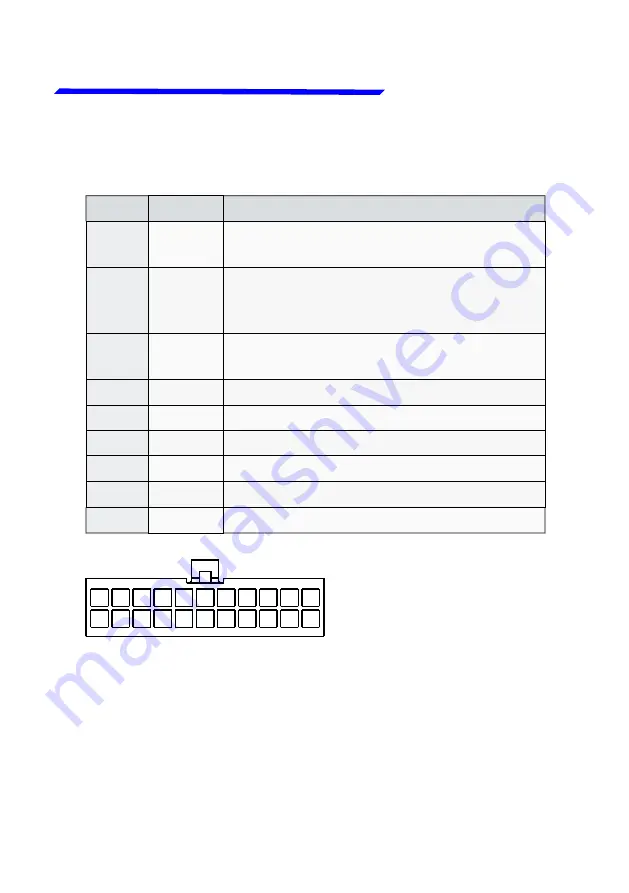

3.3 - (22 POLE) CONNECTOR TABLE

Molex P/N 43025-2200

(22 pole housing). View

from wire insertion side.

1

11

22

12

Note1

Since the current consumption is 60mA, consider a

breaker of 1A or less.

Summary of Contents for Omnia57-80 Series

Page 4: ...Examples of available screens ...

Page 60: ......