PVML USER INSTRUCTIONS ENGLISH 00079591 – 01/05

®

In particular, fault diagnosis is essential to enhance

pump and plant reliability.

6.8.1 Casing, seal plate, diffuser and impeller

a) Inspect for excessive wear, pitting, corrosion,

erosion or damage and any sealing surface

irregularities.

b) Replace as necessary.

6.8.2 Motor shaft and stub sleeve (if fitted)

Although the pump is in most executions of the “dry

shaft design” Replace if grooved, pitted or worn.

6.8.3 Gaskets and O-rings

After dismantling, discard and replace.

6.8.4 Motor bearings

a) It is recommended that bearings are not re-used

after any removal from the shaft.

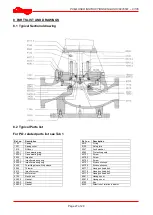

6.9 Assembly

To assemble the pump consult the sectional drawings,

see section 8,

Parts list and drawings

.

Ensure threads, gasket and O-ring mating faces are

clean. Clean all parts carefully before assembly and

replace any which are worn or damaged. Apply thread

sealant to non-face sealing pipe thread fittings.

6.9.1 Fitting the neck bus

This procedure describes the fitting of the neck

(throttle) bush into the casing cover.

��

Clean the mounting surfaces of the neck bush

[4132] and the casing cover.

��

Fit the neck bush in the casing cover on the top

side.

The neck bush should be fixed in relation to the casing

cover using 3 set screws [6570.3].

��

Drill 3 holes at 120

°

intervals in the partition

between neck bush and casing cover. Drill the

holes to a depth such that the set screws [6570.3]

do not protrude above the surface of the neck

bush and the casing cover.

��

Tap screw thread into the 3 holes and remove the

metal chips.

��

Mount the set screws.

��

Fix the set screws using a centre point.

6.9.2 Fitting the impeller wearing rings

The procedure specified below is to be followed

with regard to the impeller wearing rings [2300.1 & 2]

on one or both sides of the impeller.

��

Clean the mounting surfaces of the impeller

wearing ring and the impeller.

��

Use the appropriate personal

protection equipment when heating and positio-

ning the impeller wearing ring.

��

Heat the impeller wearing ring to a temperature

of 120 to 150

°

C. Take care if the impeller

wearing ring has a sprayed-on layer of chrome

as this may break away if heating or cooling is

carried out quickly.

��

Push the impeller wearing ring right over the

impeller and let the whole assembly cool down.

��

Tap screw thread into the 3 holes and remove

the metal chips.

��

Mount the set screws [6570.2].

��

Fix the set screws using a centre point.

6.9.3 Fitting the case wearing rings

The procedure specified below is to be followed

with regard to the installation of the case wearing

ring [1500.1] in the diffuser. The same procedure

can be followed when installing the case wearing

ring in the casing cover. Read casing cover instead

of diffuser.

��

Clean the mounting surfaces of the case

wearing ring [1500.1 & 2], the diffuser gland

and the pump casing.

��

Use the correct personal

protection equipment when cooling and

positioning the case wearing ring.

��

Cool the case wearing ring using liquid

nitrogen.

��

Lower the case wearing ring vertically in the

diffuser and wait until the case wearing ring is

tight.

��

Drill 3 holes at 120

°

intervals in the partition

between the case wearing ring and diffuser.

Drill the holes to a depth such that the set

screws [6570.2] do not protrude above the

surface of the case wearing ring and the

diffuser plate.

��

Tap screw thread into the 3 holes and remove

the metal chips.

��

Mount the set screws [6570.2].

��

Fix the set screws using a centre point.

Page 22 of 29