PHL USER INSTRUCTIONS ENGLISH 00079593

–

10/10

Page 12 of 31

Fill the space between the filler blocks and the

foundation frame with filler plates.

Check that the bolts fit easily into the bolt holes of

the flanges.

Fix the foundation bolts by filling the recesses with

non-shrinkable mortar.

Let the mortar set in accordance with the

specifications.

4.4

Adjusting the foundation frame

To make sure that the unit is leveled, use a calibrated

machine levelwith an accuracy of 0.02 mm/m

1

.

Measure along the shaft of the electric motor in both

directions, or, if this is not possible, along the seal

plate. If the mechanical seal is fitted with a guard, this

should be removed.

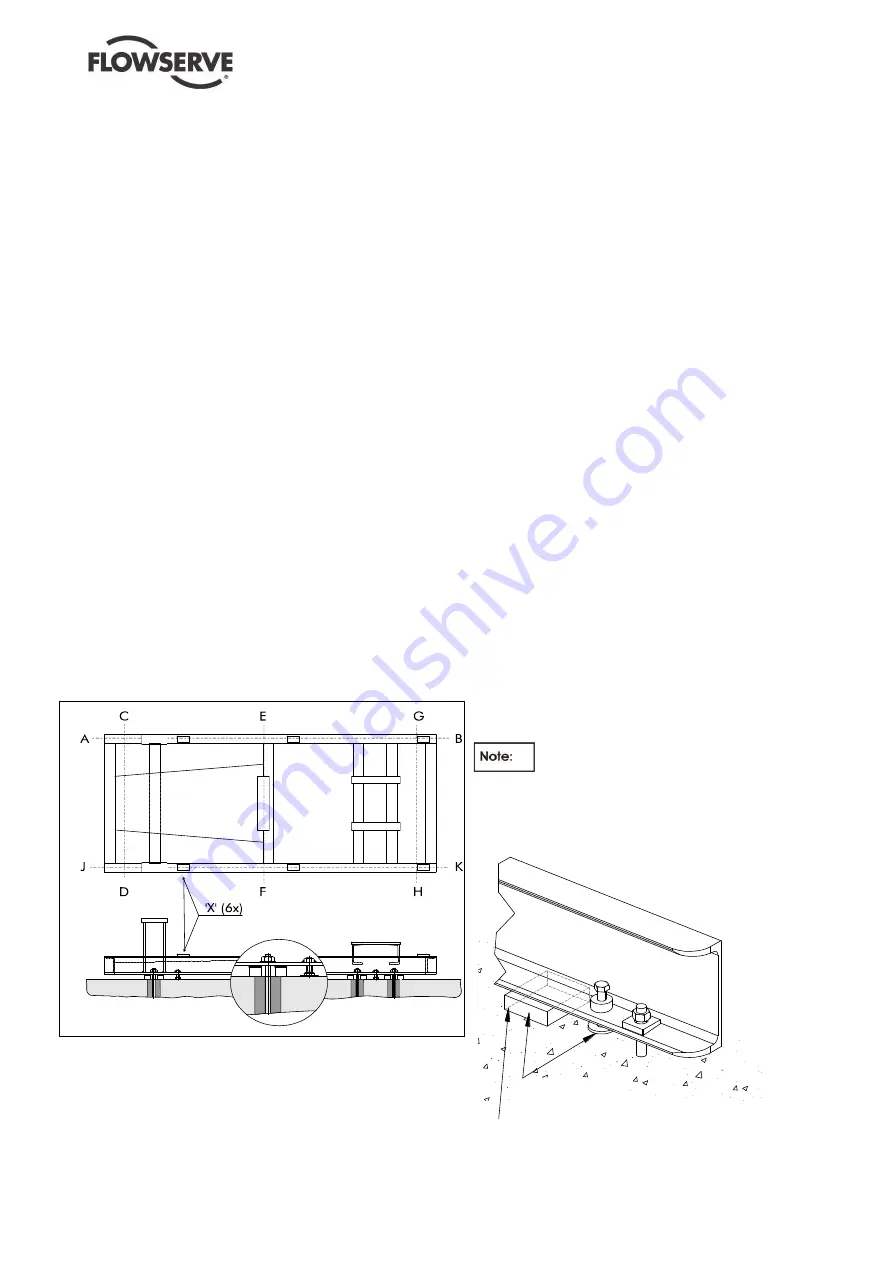

Level the foundation frame in the direction A-B

with an accuracy of 0.05 mm/m

1

using the

adjusting bolts, see Figure 3. Fill the space

between the filler blocks and the foundation frame

with thin filler plates.

Tighten the foundation nuts, along the A-B axis, by

applying a moment equal to ¼ the maximum

permissible moment (M

max

) of the foundation bolt.

Level the foundation frame in the directions C-D,

E-F and G-H with an accuracy of 0.05 mm/m

1

using the adjusting bolts. Fill the space between

the filler blocks and the foundation frame with thin

filler plates.

Tighten the other foundation nuts by applying a

moment equal to ¼ the maximum permissible

moment (M

max

) of the foundation bolt.

Check that the nuts of the foundation bolts are still

tight.

Place the electric motor on the pump center line,

using shims between the supporting faces of the

foundation frame and the motor base.The

maximum allowable deviation in axial or radial

direction is 0.05 mm and depends on the type of

coupling.

Retract all foundation bolts and check that the

foundation frame is level in all directions with

an accuracy of 0.05 mm/m

1

.

Check the position and level along the center

line of the suction and discharge nozzles.

Adjust, if necessary, by following the

procedures given above.

Fill in the outer edges of the foundation frame,

including filler plates,

completely,

using non-

shrinkable mortar (e.g. Pagel V1 or equivalent)

and let this set in accordance with the

specifications.

Grout the foundation frame, via the fill opening

(see Figure 3),

completely,

using non-

shrinkable concrete and let this set in

accordance with the specifications.

Check that the nuts of the foundation bolts are

still tight and tighten, if necessary, by applying

the correct moment (¼ M

max

).

If the guard of the mechanical seal was

removed for levelling, replace it in the correct

position.

If necessary, draw up a report on the whole

adjustment procedure.

4.4.1 Baseplate not Intended for Grouting but

Installed on Concrete Foundations

According to the figure 4.3.1 and 4.4.1 the

baseplate will not be grouted but only a sealing

shall be provided. During the preparation, as

indicated on the General Arrangement drawing a

certain number of openings into the sealing must

be guaranteed. After the sealing the blocks used to

realise the openings must be removed. Blocks has

to be wider than the baseplate longitudinal beam in

order to guarantee the opening for the drainage.

The filler grout must be of a non-

shrinkable kind and fill up the space between the

beams and the concrete poor. Make sure that filler

grout is dry before removing the blocks.

Not supplied

BLOCK TO BE REMOVED

AFTER THE SEALING

Figure 4.3.1

Figure 3: Adjusting foundation frame

BLOCK TO BE REMOVED AFTER

APPLYING THE FILLER GROUT