1 3

CY

N I

I E

G B

•

Follow instructions for lubricat-

ing, chain tensioning and chang-

ing accessories.

Improperly tensioned

or lubricated chain may either break

or increase the chance for kickback.

•

Keep handles dry, clean, and

free from oil and grease.

Greasy,

oily handles are slippery causing loss

of control.

•

Cut wood only. Do not use chain

saw for purposes not intended.

For example: do not use chain

saw for cutting plastic, masonry

or non-wood building materials.

Use of the chain saw for operations

different than intended could result in a

hazardous situation

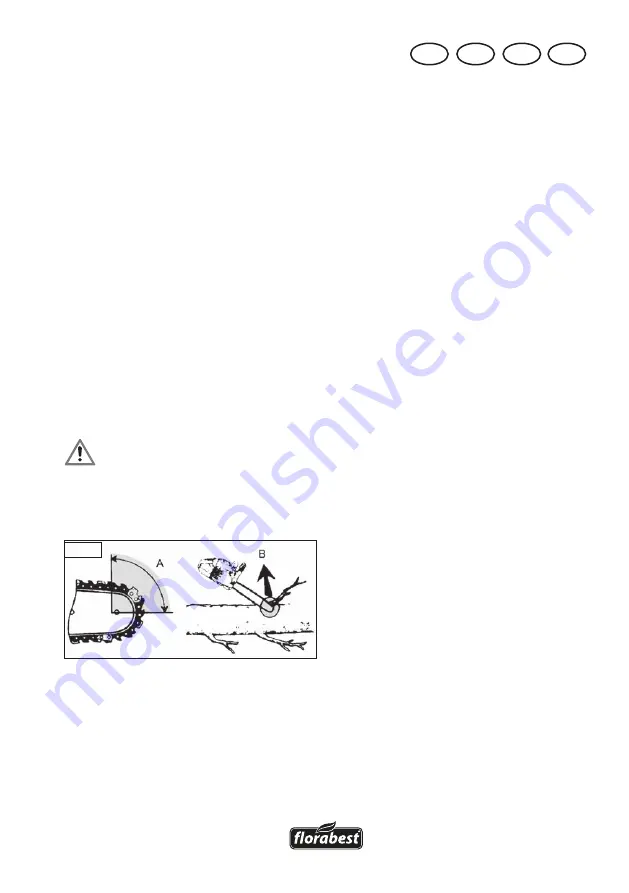

Causes and operator

prevention of kickback

Beware of kickback! Be careful of

kickback of the machine during

work. There is danger of injury

here. You can avoid kickbacks by

exercising caution and using a cor-

rect sawing technique.

Fig. 1

tip of the guide bar touches an object,

or when the wood closes in and pinch-

es the saw chain in the cut

• Tip contact in some cases may cause

a sudden reverse reaction, kicking the

guide bar up and back towards the

• Pinching the saw chain along the top

of the guide bar may push the guide

bar rapidly back towards the operator.

• Either of these reactions may cause

you to lose control of the saw which

could result in serious personal injury.

Do not rely exclusively upon the safety

devices built into your saw. As a chain

saw user, you should take several steps

to keep your cutting jobs free from ac-

cident or injury.

or incorrect operating procedures or condi-

tions and can be avoided by taking proper

precautions as given below:

•

Maintain a firm grip, with

thumbs and fingers encircling

the chain saw handles, with

both hands on the saw and po-

sition your body and arm to al-

low you to resist kickback forc-

es.

by the operator, if proper precautions

are taken. Do not let go of the chain

saw.

•

Do not overreach and do not cut

above shoulder height.

This helps

prevent unintended tip contact and

enables better control of the chain saw

in unexpected situations.

•

Only use replacement bars and

chains specified by the manu

-

facturer.

Incorrect replacement bars

and chains may cause chain breakage

and/or kickback.

•

Follow the manufacturer´s

sharpening and maintenance

instructions for the saw chain.

Decreasing the depth gauge height

can lead to increased kickback.

Summary of Contents for FKS 2200 G4

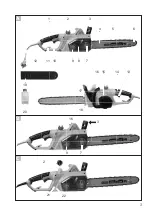

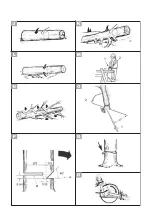

Page 3: ...3 C 1 2 3 5 6 17 A 14 13 15 16 7 9 7 9 11 12 19 B 2 4 10 8 3 16 20 21 22 18...

Page 4: ...4 R N S Q P O M L K 1 2 1 2 3...

Page 30: ...3 0 G R CY 16 180 ml A 1 2 3 4 5 6 O 17 16 15 13 14 18 9 7 8 10 12 19 20...

Page 32: ...3 2 G R CY 7 1 Lwa dB II...

Page 33: ...3 3 CY G R 460 mm...

Page 34: ...3 4 G R CY A...

Page 35: ...3 5 CY G R 30 mA H05RN F 75 2 5 mm2...

Page 36: ...3 6 G R CY N...

Page 37: ...3 7 CY G R...

Page 38: ...3 8 G R CY 1 E 1 B...

Page 39: ...3 9 CY G R 1 A A O B...

Page 40: ...4 0 G R CY FI 30 mA A 1 10 3 5 17 15 13...

Page 41: ...4 1 CY G R 11 18 1 2 7 8 3 5 4 5 4 45 5 24 5 4 5 23 23 5 6 5 9 7 8 25 8 7...

Page 42: ...4 2 G R CY 10 9 N 1 kg 2 10 min B 1 16 2 7 3 9 9 4 7 5...

Page 43: ...4 3 CY G R A 4 C 21 C 22 190 ml Parkside Grizzly 6 8 C 1 2 2...

Page 44: ...4 4 G R CY D 1 2 3 3 16 4 1 16 5 14 13 14 6 13 E 1 2 3 3 16 4 1 16 5 6 3 3 16 7...

Page 45: ...4 5 CY G R 26 F 1 2 3 7 9 8 4 4 5 4 45 5 24 5...

Page 46: ...4 6 G R CY 2 15 18 cm...

Page 47: ...4 7 CY G R 1 2 1 45 2 3 A 1 3 45 4 B 5 cm 1 10...

Page 48: ...4 8 G R CY 5 6 7...

Page 49: ...4 9 CY G R 1 2 3 2 1 3 3 1 3 4 1 2 3...

Page 50: ...5 0 G R CY A 8 A 4 26 10 24 A 5 A 5 A 4 A 4...

Page 51: ...5 1 CY G R 10 G 30 85 0 65 mm...

Page 52: ...5 2 G R CY H 1 2 3 4 0 mm 4 5 6 4 mm 7 8 0 65 mm 5 10 F 1 12 2 8 5 4 3 A 4...

Page 53: ...5 3 CY G R 4 26 5 4 5 8 F 4 10 1 A 12 2 8 5 4 3 5 8...

Page 55: ...5 5 CY G R A 13 ser vice ser vice ser vice A 5 A 5 A 5 service...

Page 56: ...5 6 G R CY 3 291822...

Page 89: ...2017 11 23_rev02_sh informativ informative Explosionszeichnung Exploded Drawing o 22 4 8 9...

Page 90: ...3 G F E D 14 13 24 9 23 3 3 16 16 1 16 24 9 23 F 4 5 25 8 24 7 4 5 0 45 I H 26...

Page 91: ......