PERFORMANCE SPECIFICATIONS

Pump

Motor

Max Amp Draw (A)

(-100) 10.0 @ 12 Vdc

(-110) 8.5 @ 12 Vdc

(-120) 7.0 @ 12 Vdc

(-300) 5.0 @ 24 Vdc

(-400) 3.8 @ 32 Vdc

(-000) 1.5 @115 Vac

Priming

................Dry........................................................10 ft (3 M)

Wet.......................................................20 ft (6 M)

Flow Rate

..........Max...............................(-110) 3.5 GPM (13 LPM)

Max...............................(-120) 3.3 GPM (12 LPM)

Max...........................................4.5 GPM (Others)

Pressure Switch

Off (-120) 35 PSI (2 bar); Others........40 PSI (2.8 bar)

On (-120) 22 PSI (1.5 bar); Others......27 PSI (1.9 bar)

Tank

Total Volume

....................................................1.1 gal. (4.1 It.)

Air Pressure Setting

......................................25 PSI (1.7 bar)

Note: The 12, 24 and 32 VDC models meet the USCG Electrical

Requirement (Title 33, Chapter I, Part 183, Subpart 1). All

pumphead wetted materials meet IAPMO TSC-14-90 and TSC

31- 90 for potable water.

Models are available in 12 and 24 Volt models, and are identified

by a prefix “R” and a CE mark on the label (i.e. R2840-100). Self

Declaration Of Conformance (SDOC) is available upon request.

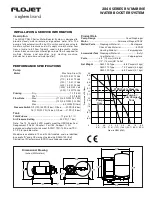

10 1/4

(260)

10 1/4

(260)

1/2

(13)

10 1/4

(260)

11 1/4

(286)

7 13/16

(198)

7 13/16

(198)

4 3/16

(106)

7 1/2

(191)

7 1/2

(191)

12 7/8

(327)

40

(2.8)

35

(2.4)

30

(2.1)

25

(1.7)

20

(1.4)

15

(1.0

10

(0.7)

5

(0.4)

0

1.0

(3.8)

2.0

(7.6)

3.0

(11.4)

4.0

(15.1)

5.0

(18.9)

6.0

(22.7)

7.0

(26.5)

8.0

(30.3)

Flow in GPM (LPM)

P

re

s

s

u

re

o

n

P

S

I

(b

a

r)

Pump &

Fully Charged

Tank

27 PSI Cut-In Pressure

Pump

Only

INSTALLATION & SERVICE INFORMATION

Dimensional Drawing

Inches (Millimeters)

Description

The FLOJET 2840 Series Water Booster System is designed to

provide steady water pressure and generous water flow. The

pump is fully automatic with a built-in switch and check valve to

maintain system pressure and will supply smooth water flow

from a trickle to full flow. Typically used in large yachts, motor

homes & bus conversions where high volume flow is required for

multiple fixtures and amenities (e.g. washing machine,

dishwasher, ice maker and water purifier).

Product Data

Pump Design

..............................................Quad Diaphragm

Motor

...............................................Permanent Magnet TENV

Wetted Parts

......Diaphragm Material...................Santoprene

Check Valve Material..........................EPDM

Housing Material...................Polypropylene

Accumulator Tank

Diaphragm Material.............................Butyl

Liner Material........................Polypropylene

Ports

....................3/4” (19 mm) HB Inlet

...................1/2” (13 mm) HB Outlet

Net Weight

........2840-100 Type................8.8 Pounds (4 kgs)

2840-110 Type.............7.3 Pounds (3.3 kgs)

2840-120 Type.............6.9 Pounds (3.1 kgs)

2840 SERIES RV/MARINE

WATER BOOSTER SYSTEM