Printed in Canada

TAC1000 Manual

June 19, 2013

Page 6

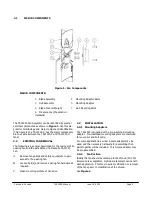

3.2

PNEUMATIC SPECIFICATIONS

Flexxaire supplies a number of pneumatic control options,

but the TAC1000-P can be operated using any air source

that meets the general specifications listed below. If your

machine has air on board then this source will be available.

If not, then a compressor will be required.

General Specifications:

Full Pitch

(default position):

0 psi (0 kPa)

Neutral Pitch

(Stop air position):

~

60 psi (413 kPa)

Reverse Pitch

(Purge position):

90 psi (620 kPa)

Max intermittent pressure:

110 psi (758 kPa)

Max continuous pressure:

90 psi (620 kPa)

4.0

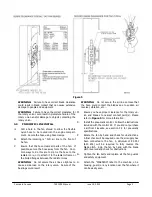

HYDRAULIC LINE INSTALL

A.

Drill a hole in the fan shroud to allow the flexible

hydraulic hose to be routed into the engine compart-

ment. Secure the hose using hose clamps.

B.

No exterior bracing should be used to prevent the

rotary union from rotating. It is imperative that a

flexible connection be used.

C.

The fan is supplied with the hydraulic line attached.

Connect the line to the hydraulic source that will be

used to operate the fan. Use thread sealant on all

connections.

D.

Ensure that the hose clears all parts of the fan. If

possible, secure the hose away from the fan. Com-

mon ways to do this are to zip tie the hose to the

radiator core, or to attach it to the radiator frame or

the bolted flanges between the radiator cores.

E.

Rotate the fan by hand and check for obstructions.

A final check will be required once the hydraulic hose

has been connected to the hydraulic source. A mini-

mum of 450 PSI (3 MPa) will be required to fully re-

verse the blade pitch. Spin the fan by hand with the

blade pitch reversed and check for obstructions. Use

Figure 5 on Page 5 for clearance between the blades

and any stationary objects.

F.

Tighten the fan belts and replace all the fan guards

and safety equipment.

G.

Attach the “WARNING” label to the machine, on a

housing, guard, or any location near the fan where it

can be easily seen.

WARNING:

Do not secure the hydraulic hose so tight

as to cause a side load on the rotary union. Failure of

the bearings could result.

WARNING:

Do not secure the hydraulic hose so

loose that the hose could contact the blades due to

sudden air reversal, vibration, etc..

H.

Install the hydraulic control valve. Follow the in-

structions included with the control kit. If you did

not purchase a kit from Flexxaire, see section 4.1 for

hydraulic specifications.

4.1

HYDRAULIC SPECIFICATIONS

Flexxaire supplies a number of hydraulic control options,

but the TAC1000-H can be operated using any hydraulic

source that meets the general specifications listed below.

If your machine has hydraulics on board then this source

will be available.

General Specifications:

Full Pitch

(default position):

0 psi (0 MPa)

Neutral Pitch

(Stop air position):

~250 psi (1.7 MPa)

Reverse Pitch

(Purge position):

450 psi (3 MPa)

Maximum allowable pressure: 1000 psi (6.9 MPa)

5.0

SERVICE AND MAINTENANCE

Flexxaire’s TAC1000 fan hub is fully sealed with o-rings,

and contains a small quantity of grease. (EP00 semi-fluid

grease) As a result, the fan itself should not require any

maintenance.

5.1

VISUAL INSPECTIONS

Under normal operating conditions TAC1000 fans do not

require any scheduled maintenance and are built to provide

thousands of hours of trouble free service. In moderate to

extreme operating conditions a visual inspection of the

moving parts in recommended from time to time to safe-

guard against fan blade damage which could lead to equip-

ment downtime and/or other damages.