EH Valves (NPS 8 through 14)

Instruction Manual

April 2009

16

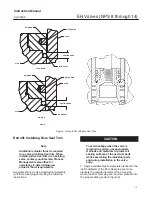

Figure 7. Stake the Threads of the Bore Seal Retainer

Bore Seal

METAL

PLUG

SEAL

VALVE

PLUG

FLOW DOWN

PISTON

RING

RETAINER

DEFORM THREAD TO

STAKE Bore Seal RETAINER

A6779 / IL

Use a drill with a 1/8 inch bit to drill out the staked

area of the thread. Drill approximately 1/8 inch into

the metal to remove the staking.

4. Locate the break between sections of the piston

ring(s). Using an appropriate tool such as a

flat-blade screwdriver, carefully pry out the piston

ring(s) from the groove(s) in the Bore Seal retainer.

5. After removing the piston ring(s), locate

the 1/4-inch diameter hole in the groove. In a

retainer with two piston ring grooves, the hole will be

found in the upper groove.

6. Select an appropriate tool such as a punch and

place the tip of the tool into the hole with the body of

the tool held tangent to the outside diameter of the

retainer. Strike the tool with a hammer to rotate the

retainer and free it from the valve plug. Remove the

retainer from the plug.

7. Use an appropriate tool such as a flat-blade

screwdriver to pry the Bore Seal plug seal off the

plug. Use caution to avoid scratches or other

damage to the sealing surfaces where the Bore Seal

plug seal makes contact with the valve plug

(figure 9).

8. Inspect the lower seating surface where the valve

plug contacts the seat ring for wear or damage

which would prevent proper operation of the valve.

Also, inspect the upper seating surface inside the

cage where the Bore Seal plug seal contacts the

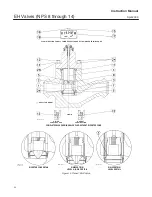

Figure 8. Installing the Bore Seal Plug Seal

Using the Installation Tool

Bore Seal

METAL

PLUG

SEAL

INSTALLATION

TOOL

A6778 / IL

VALVE

PLUG

HORIZONTAL

REFERENCE

SURFACE

FLOW DOWN

NOTE: PRESS THE INSTALLATION TOOL OVER THE VALVE PLUG UNTIL THE

TOOL CONTACTS THE HORIZONTAL REFERENCE SURFACE OF THE VALVE

PLUG.

cage, and inspect the sealing surface where the

Bore Seal plug seal makes contact with the plug

(figure 9).

9. Replace or repair trim parts according to the

following procedure for lapping metal seats,

remachining metal seats, or other valve plug

maintenance procedures as appropriate.

Lapping Metal Seats

(Bore Seal Constructions)

Before installing a new Bore Seal plug seal, lap the

lower seating surface (valve plug to seat ring,

figure 9) following appropriate procedures in the

Lapping Seats section of this manual.

Remachining Metal Seats

(Bore Seal Constructions)

A valve plug with a Bore Seal metal plug seal

features two seating surfaces. One seating surface

is found where the valve plug contacts the seat ring.

The second seating surface is found where the Bore

Seal plug seal contacts the upper seating surface in

the cage. The cage does not require any machining,

even when the plug and / or seat ring have been

machined.