Model A31A

11

Table 6. Torque Values for Fasteners

FASTENER NOMINAL SIZE

#10

1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

1

1-1/8

Retaining

Pounds-inch

Pounds-Foot

Retaining

Ring

41

100

220

400

53

83

119

166

296

480

720

1000

Ring

Screws

Newton

S

meters

4.6

11

25

45

72

112

161

225

401

651

976

1356

G

Pounds-inch

Pounds-Foot

Gasket

Retaining

35

81

167

295

39

59

86

119

210

330

480

617

Retaining

Bolts

Newton

S

meters

Bolts

4.0

9.2

19

33

53

80

117

161

286

447

651

837

Nore: These values are based upon standard materials, S66286/Inconel screws and ASTM A193GRB6 bolts. For other special fasterer materials, please contact your Fisher Controls

sales office or sales representative.

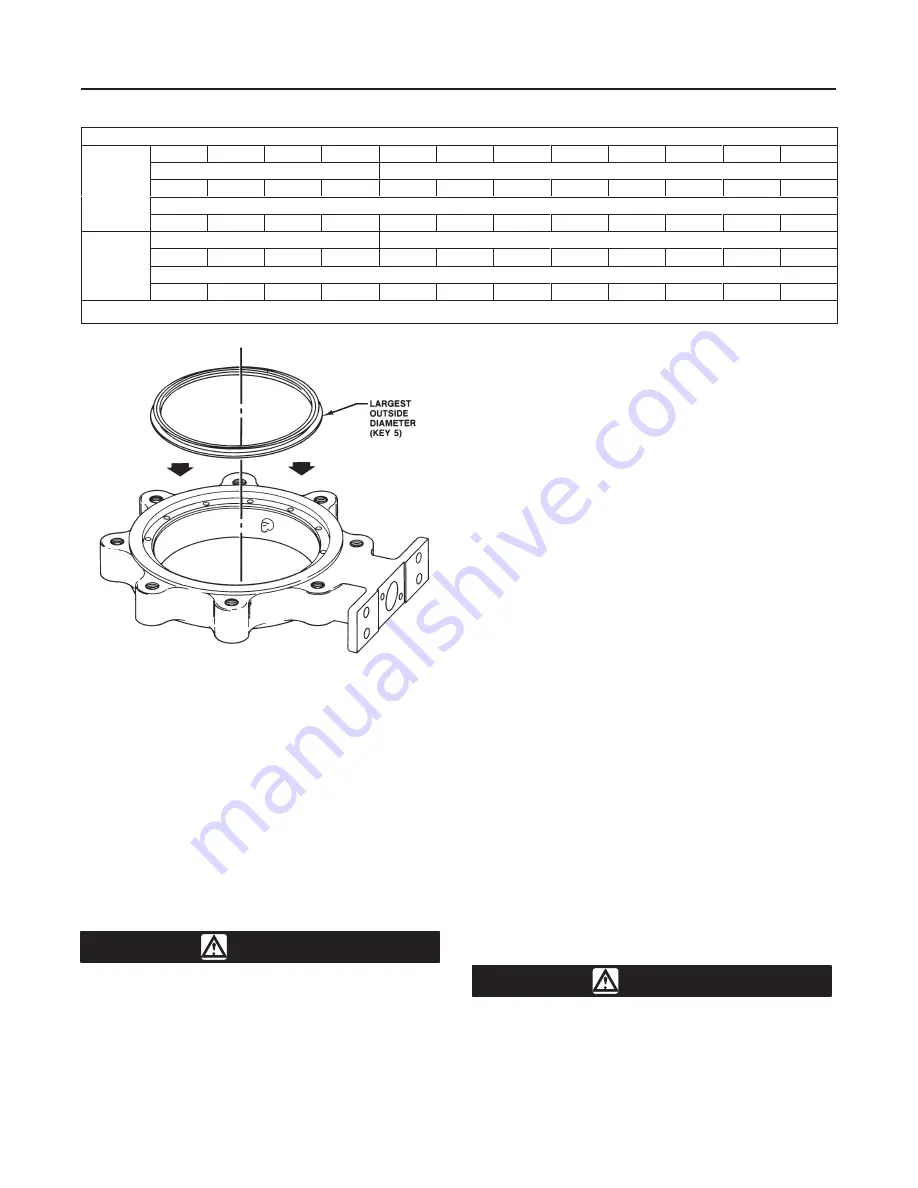

Figure 8. Typical Seal Installation

A5251-1*/IL

Removing the Valve

1. Disconnect any operating lines providing air pres-

sure, electric power, or a control signal to the actuator.

Be sure the actuator cannot suddenly open the valve.

Vent the power actuator loading pressure.

2. Use bypass valves or completely shut off the pro-

cess to isolate the valve from process pressure. Re-

lieve process pressure on both sides of the valve.

Drain the process media from either side of the valve.

CAUTION

Damage to the valve disk can occur if

the disk is not closed when the valve is

being removed from the pipeline. If nec-

essary, stroke the actuator to place the

disk in the closed position while remov-

ing the valve from the pipeline.

3. Loosen the flange bolting that holds the valve.

Make sure the valve cannot slip or twist while loosen-

ing and removing the bolting.

4. Before removing the valve from the pipeline, make

sure the valve disk is closed. Removing the valve with

the disk open could cause damage to the disk, piping,

or pipe flanges.

5. After removing the valve from the pipeline, move

the valve to an appropriate work area. Always support

the valve properly.

6. When valve maintenance is complete, refer to the

Installation procedures in this manual.

Seal Maintenance

Note

For larger valves, it is possible to re-

place the seal (key 5) while the actuator

is mounted to the valve and can be ac-

complished by cycling the valve to 90

degrees open.

Key numbers in this procedure are shown in figure 9

unless otherwise indicated.

1. After removing the valve from the pipeline, remove

the manual or power actuator. Manually rotate the up-

per shaft (key 3) counterclockwise until the disk has

moved a full 180 degrees away from the closed posi-

tion.

WARNING

Avoid personal injury or property dam-

age caused by the impact of a falling or

tipping of a large valve. Support large

valves during maintenance.