Type 4000

10

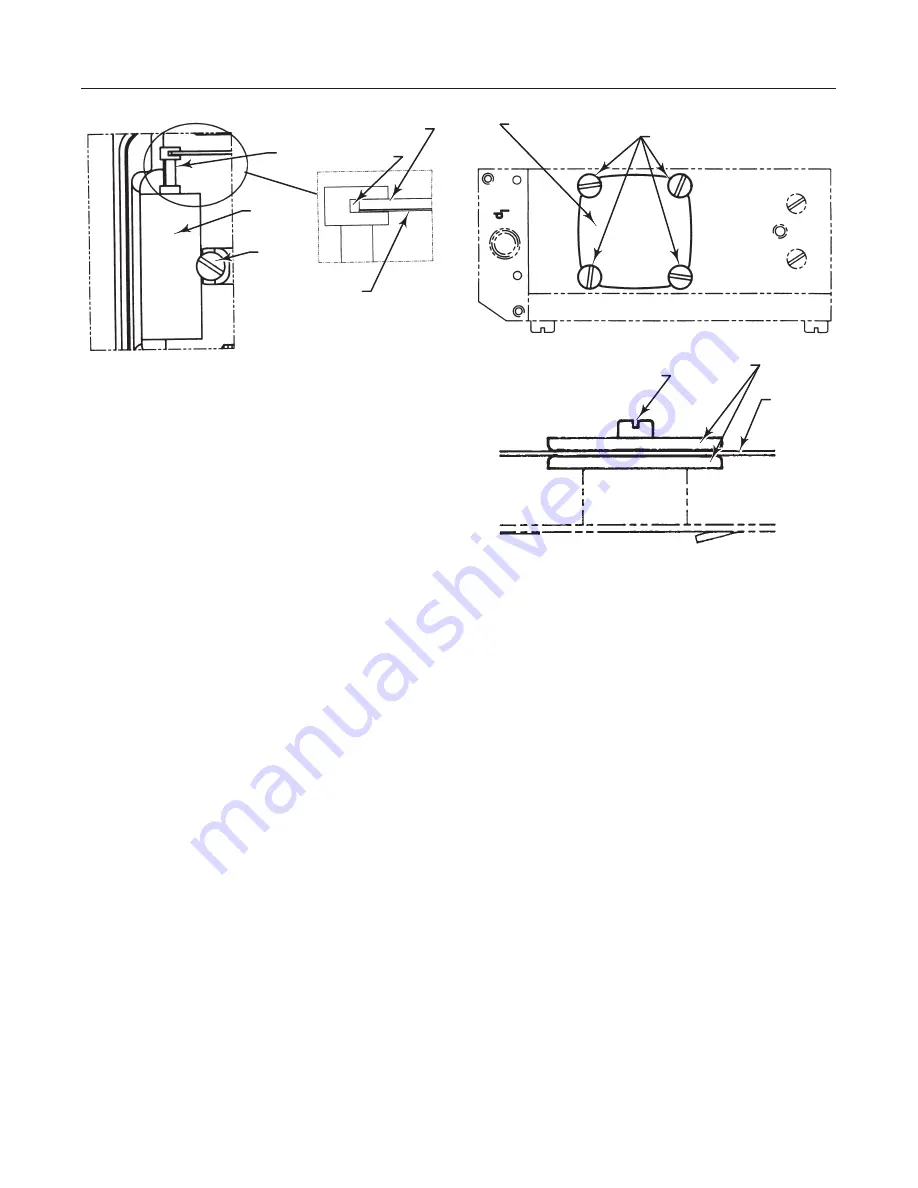

Figure 12. Pilot Valve Assembly

SCREW

PILOT

VALVE

ASSEMBLY

SPOOL

SPOOL GROVE

BALANCE ARM

LEAF SPRING

A7200 / IL

5. Check the O-rings, then secure and install the pilot

valve assembly to the positioner housing and secure it

with the screw. Make sure that the leaf spring on the

balance arm is properly fitted in the spool groove.

6. Check again to insure smooth operation of the as-

sembly.

Replacing the Diaphragm

Refer to figure 13.

1. Loosen the four screws and remove the diaphragm

cover.

2. Loosen the screw that secures the diaphragm. Re-

move the diaphragm and washers.

When installing the diaphragm make sure to place one

washer on each side of the diaphragm. Make sure that

the raised circle on the washers is facing the dia-

phragm.

3. Install the screw and tighten.

4. Check the O-ring on the diaphragm cover, then

install and secure the cover with the four screws.

Replacing Gauges

1. Shut off supply pressure and process lines to the

positioner.

2. Remove the defective gauge from the adapter

housing.

3. Coat the threads of the replacement gauge with a

sealant (Zink plate No. 770 or equivalent).

Figure 13. Diaphragm

DIAPHRAGM COVER

SCREWS

SCREW

WASHERS

DIAPHRAGM

A7201 / IL

4. Screw the replacement gauge into the adapter

housing gauge connection.

5. Apply supply pressure to the positioner. Using a

soap solution, check around the ports and connections

for leaks.

Removing the Positioner

1. Shut off supply pressure and process lines to the

positioner.

2. Remove the actuator cover.

3. Remove the flathead screw that secures the feed-

back lever to the positioner spindle. Remove the feed-

back lever from the spindle.

4. Refer to figure 3. Remove the four mounting

screws from the bottom of the adapter housing.

5. Lift the positioner off the adapter housing.

Replacing the Positioner

1. Replace the positioner on the actuator by perform-

ing the mounting and connection procedures in the

“Installation” section.

2. Calibrate the positioner by performing the proce-

dures in the “Calibration” section.