Lit. No. 49591, Rev. 05

5

July 15, 2020

27775, 28069, 57000, 57000‑1, 57000‑3

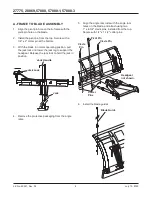

HEADGEAR TO A‑FRAME ASSEMBLY

NOTE: For easier assembly and installation,

vehicle and all snowplow components should

be on a smooth, level, hard surface, such as

concrete.

1.

Set aside the blade guides and parts bag. The

vehicle electrical harnesses and the Owner's

Manual packet are in the bag with the headlamp

box.

2.

Remove the packaging hardware securing the

headgear to the A‑frame, except the clevis pins

and red shipping brackets.

3.

Remove the blocking and hardware securing the

A‑frame to the pallet.

4.

While supporting the headgear, remove and

retain the four pins, and discard the red shipping

brackets.

5.

Align the holes in the headgear assembly with

the middle hole in the A‑frame assembly. Attach

the A‑frame to the headgear with two step pins

and 1/4" x 1‑1/2" cotter pins. Insert the step pins

from the outside of the headgear. Verification of

proper A‑frame position will be made during final

adjustments.

1/4" x 1-1/2"

Cotter Pin

A-Frame

Headgear

Assembly

Step

Pin