REV. 1-7-19 Page 12

Round Flat Disc

MT FIRE PIT MAINTENANCE - SECTION A

1. The fire pit should be inspected and cleaned before initial use at least annually by a qualified field service person.

2. Any component that is found faulty must be replaced with an approved component.

3. Any tampering or modifying with the fire pit is dangerous and voids all warranties.

4. During winter months in cold climates and various seasons operation the fire pit may be affected by weather

conditions. It is recommended to use a cover/lid for your fire pit to protect it from humid/rainy weather conditions

when not in use. Heavy rains/downpours could affect the fire pit operation if not covered; if this occurs

ensure you allow the fire pit time to dry out before attempting to operate.

NOTE

: If a combustible type cover is used

over the fire pit when not in use be sure to remove it before operation to prevent a severe safety hazard.

5. Over time stainless steel parts can discolor when heated, usually a golden or brown hue. This discoloration is normal

and does not affect the performance of the appliance.

MT TROUBLE SHOOTING - SECTION A

Symptom

Remedy

Fire pit won’t light

1. Bleed gas line.

2. Ensure all gas supply lines are turned ON.

3. Ensure there is not too much media overtop of burner; it can inhibit gas from flowing.

4. Check gas pressure.

Low flame

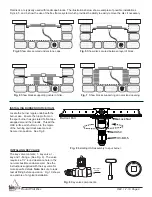

1. Ensure the base media is at least 1 to 2-inches in diameter and top media is no more than

1-inch over top of burner.

2. Ensure all shut-off valves and key valve is fully open.

3. Check for spider webs inside the orifice.

4. Check gas pressure.

Water in my fire pit

1. Excess dust/sand material from media may be blocking the weep holes to relieve water.

Remove all media and unplug weep holes. Clean or install new media free of dust and dirt.

2. Ensure fire pit enclosure has proper drainage for water and proper ventilation to dry out.

3. Recommend to purchase a cover/lid to keep excessive water out of the fire pit.

Whistling Noises

1. Check media to ensure it is not too tightly packed around the burner tube.

2. Ensure a non-whistling flex connector is being used.