Page 3

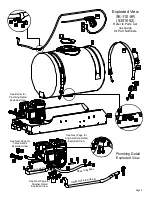

Ref. #

Fimco #

Mfg. Part #

Description

Qty.

1

5002476

CP36303-PP

Poly Body (AA6B)

1

2

♦ ♦

CP36307-PPB

Washer

2

3

* *

CP38726-VI

Shut-Off Washer, Viton

1

4

♦ ♦

CP36306-302SS

Spring

1

5

♦ ♦

CP36304-SS

Stem

1

6

* *

CP7717-2/108-VI O-Ring, Viton

1

7

* *

CP7717-2/209-VI O-Ring, Viton

1

8

5086043

CP36302-PP

Poly Body Insert (Black)

1

9

5078178

CP36301-NY

Handle (Gray)

1

10

5101220

CP36308-SS

Groove Pin

1

11

♦ ♦

CP36309-302SS

Retaining Clip

1

12

5102022

F14

Pipe Plug, 1/4" MNPT

1

13

5117281

CP38725-SS

#10-24 x 5/16" Phillips

Truss Head Machine Screw

1

* * Available only in Repair Kit

♦ ♦: Only Available in Complete Assembly

Polypropylene with stainless steel spring

Excellent chemical resistance

EPDM O-Rings

Fore pressure to 150 p.s.i.

1/4” port for pressure gauge

Choice of 1/2” or 3/4” NPT (M) inlet & (F) outlet connections

Piston Type Pressure Relief/Regulating Valves

Bypasses excess fluid. Adjustable to maintain control of line pressure at any pressure within the valve operating range.

Selected pressure setting firmly held in place by locknut. Extra large passages to handle large flows.

Cast Iron

8-Roller Pump Assembly

#5271509 (Hypro Mfg. Part #: 7560C-R-01)

* * Available only in Repair Kit #7771794

(3430-0381)

♦ ♦ Only Available in Complete Assembly

GPM

HP

GPM

HP

GPM

HP

GPM

HP

GPM

HP

GPM

HP

GPM

HP

600

14.0

0.45

13.1

0.87

12.1

1.41

11.2

1.98

10.6

2.5

10.0

3.1

9.1

3.7

250 PSI

300 PSI

Pump

Speed

(RPM)

0 PSI

50 PSI

100 PSI

150 PSI

200 PSI