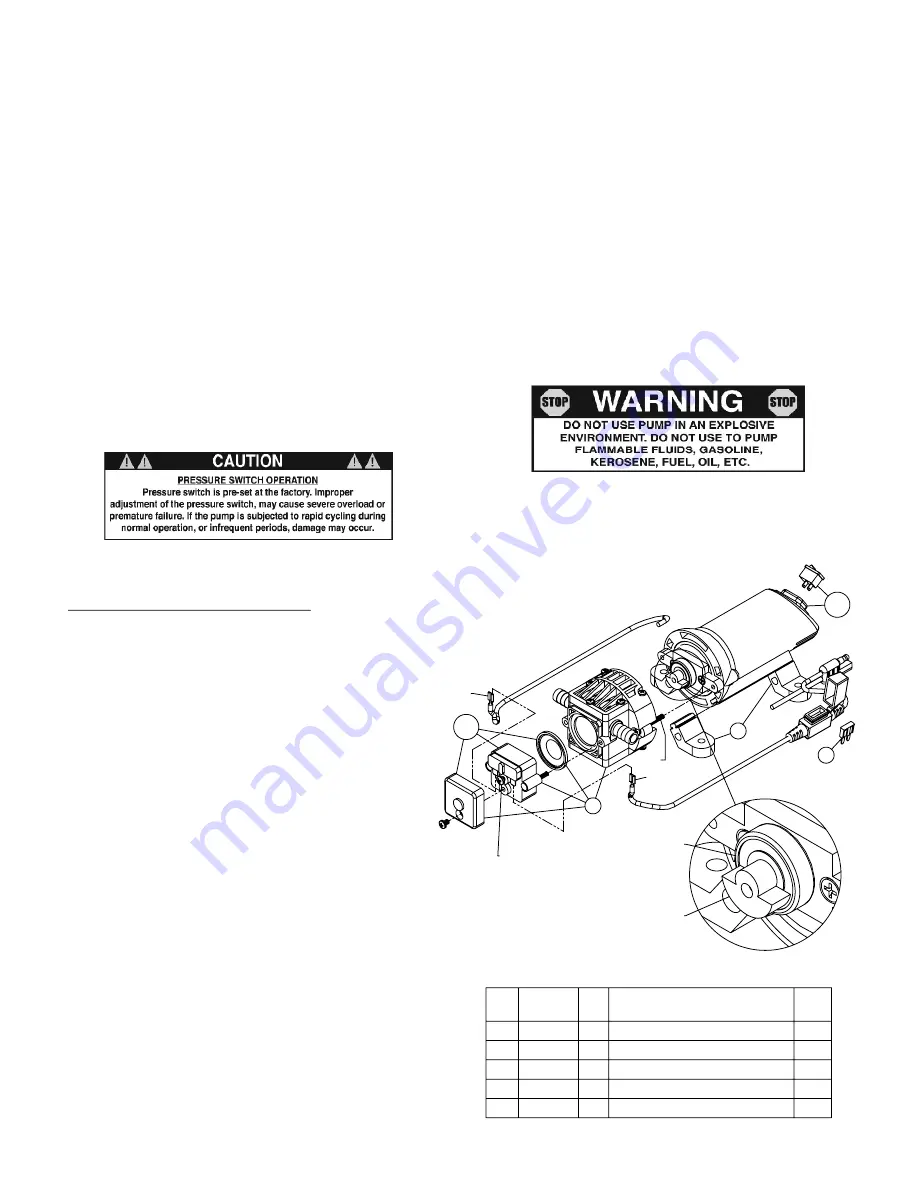

(12 Volt, 4 Amp, 1.0 gpm, 35 psi)

counterweight

"Half-Moon"

Description

5 Amp Mini Fuse

Rocker Switch

Pump Foot (Pkg. of 4)

Pump Assembly w/Pressure Switch

Pressure Switch w/Diaphragm

- Insure a tight connection at the battery clips.

similar and this should restore most of your prime.

break them free with some good quality lubricant or something

other. If these 2 pieces are 'stuck' together, you will need to

freely, and they both need to spin INDEPENDENT of each

- Both the counterweight and the bearing need to spin

- Unscrew (2) screws "S". This will allow you to inspect the

Periodically take the screen at this location out and clean it.

solution in the tank will be away from this inlet location.

may need to tilt the tank backwards a little bit so any

tank should be empty while performing this, otherwise you

this screen. (see exploded view later in this manual) The

tank. You will need to unscrew the knurled nut to access

- Check line strainer (screen) at the inlet location, at the

Pump runs, but does not prime:

know that your lead wire assembly needs to be replaced.

volts to the pump. If your pump runs after doing this, you will

them together. This will insure you are getting the full 12

screwed to the rocker switch, off of the switch and twist

screws, and 'hot-wire' it together. Take the (2) wires that are

the lead wire assembly (#5274443) with the (2) phillips head

Another thing you can try is to take apart the switch box on

when you do this, you know you will need to replace your

pressure switch cap before doing this) If your pump runs

over and touch terminal "B". (You will need to remove the

of the spade terminal of the pressure switch, and cross it

If none of the above will work, try pulling wire terminal "A" off

bearing and counterweight.

pressure switch.

Part

Item

Qty

Number

5095202

5157204

5275531

5157201

5157207

3

4.1

3.1

1

2

No

1

1

1

1

1

Pressure adjustment

screw (Factory Preset)

3.1

3

- Make sure you 12 volt source (battery) is fully charged.

- Make sure BOTH on/off switches are in the 'on' position (-).

replace with new fuse. (5 Amp mini-blade fuse...#5157204)

- Check inline fuse on the wires on the pump. If blown,

Troubleshooting a 1.0 g.p.m. Pump:

Pump will NOT run:

"A"

List

37.95

23.95

6.99

4.99

3.99

Price

2

Bearing

"B"

"S"

1

4.1

#5275702 Pump

Conditions of weather and terrain must be considered when

setting the sprayer. Do not spray on windy days. Protective

clothing must be worn in some cases.

Be sure to read the chemical label(s) correctly!

After testing, add water and chemical to the tank. Adjust the

pressure and spray as you did in the testing procedure.

Page 2

Drain all water out of sprayer, paying special attention to the

pump, handgun, and valve(s). These items are especially

prone to damage from chemicals and freezing weather.

The sprayer should be winterized before storage, by pumping

a solution of RV Antifreeze through the entire plumbing

system. This antifreeze solution should remain in the plumbing

system during the winter months. When spring time comes

and you are preparing your sprayer for the spray season, rinse

the entire plumbing system out, clearing the lines of the

antifreeze solution. Proper care and maintenance will prolong

the life of your sprayer.

Winter Storage

After Spraying

After use, fill the sprayer tank part way with water. Start the

sprayer, and allow the clear water to be pumped through the

plumbing system and out through the spray nozzles.

Refill the tank about half full with plain water and use FIMCO

Tank Neutralizer and Cleaner, and repeat cleaning instructions

above.

Flush the entire sprayer with the neutralizing/cleaning agent,

then flush out one more time with plain water. Follow the

chemical manufacturer's disposal instructions of all wash or

rinsing water.

For the boom, (if applicable) remove the tips and screens from

the nozzle assemblies. Wash these items out thoroughly. Blow

the orifice clean and dry. If the orifice remains clogged, clean it

with a fine bristle (NOT WIRE) brush, or with a toothpick. Do

not damage the orifice. Water rinse and dry the tips before

storing.

WARNING: Some chemicals will damage the pump valves

if allowed to soak untreated for a length of time! ALWAYS

flush the pump as instructed after each use.

Winter Storage