Page 9

1. Start by sliding Items 4, 3, 2 onto the boom tube (Item 1) as

shown, leaving about 1/2” to 3/4” between the end of the boom tube

and make sure the “Long” portion of Item 3 is facing the nozzle end.

2. Slide the (complete) end nozzle assembly onto the stainless steel boom

tube, with a somewhat “twisting” motion, so that the end face of the boom

tube “butts” up against the surface face inside the nozzle body.

3. Now push the “compression olive” (Item 3) against o-ring (Item 2) and slide

(both) into the nozzle body opening firmly.

4. Firmly tighten flynut (Item 4) onto threads of nozzle body.

5. Repeat for other side.

End Nozzle Assembly Procedure

For Boomless “Wet”Boom

Your boom will come with the (2) end nozzle assemblies

NOT affixed to your boom tube. Follow the instructions

below to attach these properly to the boom tube, as

shown.

Assembled

End Nozzle

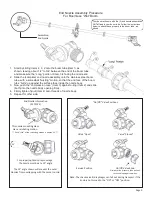

End Nozzle Informa on

(5275122)

This nozzle moun ng stem

Has a ratche ng mo on.

** Each “click” of the ratche ng mo on is approx. 15° **

For proper/op mal spray coverage,

The nozzle must be at a 15° angle

The 15° angle shown will prevent the outer

Nozzles from overlapping with the center nozzle.

15°

“On/O

ff

” Valve Posi ons

Valve “Open”

Valve “Closed”

Service Posi on On/O

ff

Valve Knob

Eliminate line pressure, then pull out

to check diaphragm condi on.

Note: The check valve & diaphragm can fall out during transport, if the

knob is not turned to the “ON” or “OFF” posi on.