ACTIVATING THE SIDE BRUSH

If the side brush needs to be used during the floor scrubbing operations (and therefore with the brush head in its working position), press the

side brush head activation/deactivation button (11) on the left-hand side of the steering column (

Fig.14

).

N.B.:

When the side brush is in function, the LED indicator light inside the button (11) will be on.

N.B.:

By pressing the button (11), the side brush head will begin to move towards the outside of the machine, and the solenoid valve will

only begin to dispense the detergent solution once it has reached its working position (valid only for scrubbing versions).

By pressing the button (11) the side brushes will start to move towards the floor and the gear motors of the side brushes will start to work

(valid only for sweeping versions).

N.B.:

In order to bring the side brush head back to its resting position, press the button (11) (valid only for scrubbing versions).

In order to bring the side brushes back to their resting positions, press the button (11) (valid only for sweeping versions).

N.B.:

If the central brush head is raised with the side brush head in its working position, the lever (4) on the steering column (

Fig.15

) can

be turned in order to bring the side brush head back to the rest position. The LED indicator inside the button (11) will nevertheless remain

on to indicate that if the central brush head is brought back to its working position, the side one will move to the right (valid only for

scrubbing versions).

If the central brush head is raised with the side brush head in its working position, by turning the lever (4) on the steering column (

Fig.15

) the

side brushes can also be brought into the rest position. The LED indicator inside the button (11) will nevertheless remain on to indicate that

if the central brush head is brought back to its working position, also the side brushes will be brought into contact with the floor (valid only for

scrubbing versions).

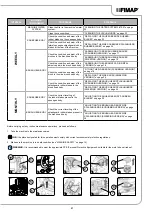

NUMBER

TYPE

DESCRIPTION

AL_60

Function

Time-out Actuator 1

AL_61

Function

Amperometric Actuator 1

AL_62

Function

Overcurrent Actuator 1

AL_63

Function

Incorrect limit switches - actuator 1

AL_64

Function

Time-out Actuator 2

AL_65

Function

Amperometric Actuator 2

AL_66

Function

Overcurrent Actuator 2

AL_67

Function

Incorrect limit switches - actuator 2

AL_68

Function

Time-out Actuator 3

AL_69

Function

Amperometric Actuator 3

AL_70

Traction

Overcurrent Actuator 3

AL_71

Traction

Incorrect limit switches - actuator 3

NUMBER

TYPE

DESCRIPTION

AL_80

Traction

Overtemperature

AL_81

Traction

Power board damaged

AL_82

Traction

Main fuse faulty

AL_83

Traction

Main contactor faulty

AL_84

Traction

Main contactor faulty - CC

AL_85

Traction

Overcurrent - traction output

AL_86

Traction

Amperometric - traction output

AL_87

Traction

Motor reading

AL_88

Traction

Electric brake fault

AL_89

Traction

Pedal fault

AL_90

Traction

Pedal pressed

AL_91

Traction

Encoder fault

ACTIVATING DETERGENT SOLUTION RECYCLING (FLR VERSION)

Upon request the machine can be fitted with a system that allows the detergent solution to be recycled so that productivity can be increased,

since the number of stops needed to empty and fill the tanks is reduced. As a result less water and detergent are used, thereby making the

operator safer, who comes into contact with the chemical products less frequently, and the operation is more environmentally friendly. If the

machine being used features the system for recycling the detergent solution, once the machine has been started up, press the FLR system

activation - deactivation button (12), on the left side of the steering column (

Fig.16

). Once the work operations have been completed, remember

to shut off the FLR system by pressing the button (12).

N.B.:

When the FLR system is in function, the LED indicator light inside the button (12) will be on.

N.B.:

At the end of the working day, perform all the procedures listed in the section “ROUTINE MAINTENANCE” on page 26.

TAG INSERTION (FFM VERSION)

To activate the automatic fleet management data recording function, which is valid for machine versions with the FFM system, after the screen

displaying the machine programming characteristics appears, insert the TAG in the slot (13) on the right-hand side of the steering column

(

Fig.17

).

N.B.:

If the owner of the TAG just inserted is not enabled to use it, the AL_11 alarm will appear on the control display.

OVERFLOW DEVICE

The machine is not equipped with an overflow device, because the volume of the recovery tank is greater than the capacity of the solution

tank. In extraordinary cases, there is a mechanical device (float) under the recovery tank lid that, when the recovery tank is full, shuts off the

air to the vacuum motor intake to protect it; the sound of the suction motor will then be deeper. Empty the recovery tank (read “DRAINING THE

25