EN

10

FZS 2050-E

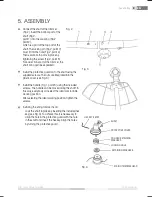

- Install the individual components in the following

order:

1. Cogged retaining washer A (also equipped

with a retaining hole)

2. Retaining washer B

3. String trimmer head

- Screw the string trimmer head on to the shaft by

turning it clockwise (attention: reverse thread)

and tighten fi rmly.

- Take the hex key out of the retaining hole.

Winding string trimmer line on to the trimmer head

1. Push in the retaining latches on the side of the

head and take off the cover (see Fig. 5, points

A&B)

2. Take the spool out of the string trimmer head.

Prepare about 2-3 m of string trimmer line with

a diameter of 1.6 mm.

3. Bend the string trimmer line in the middle and

secure the bend in the groove (see Fig. 5,

point C)

4. Wind both ends in parallel on to the spool in

a clockwise direction. Secure the ends of the

wound on string trimmer line into the prepared

holes (see Fig. 5, point D)

5. Return the spool back into the string trimmer

head and secure in place with the cover

(see Fig. 5, points E&F)

WARNING

Use only good quality nylon string trimmer line with

a diameter of 1.6 mm. Never use wire or wire-

reinforced string trimmer line instead of the nylon

string trimmer line. Only use the original string

trimmer head.

B

C

D

E

F

A

Fig. 5

Assembly

Summary of Contents for FZS 2050-E

Page 1: ...EN ...

Page 17: ...EN 18 FZS 2050 E Notes ...