6

Commissioning

Note

Commissioning should only be conducted by qualified personnel.

Requirements

– The valve is fully mounted and connected.

– If incompressible media are used, fill the piping with the medium.

Check operating conditions

Check operating conditions and limit values (

è

Technical data).

Check connection points for tightness.

Check compatibility of the devices in the system for maximum pressure (con

sider pressure peaks). If necessary, adjust the application parameters.

Placing valve in operation

Slowly apply medium pressure to the valve.

è

The valve closes.

Note

If medium pressure is applied suddenly, the valve opens briefly.

7

Operation

Warning

Risk of injury due to hot surface!

The valve can become hot at high media temperature.

Do not touch the valve during operation or immediately afterward.

Observe the operating conditions.

Observe permissible limits.

After longer standstills:

Actuate the valve several times and check for correct function.

8

Maintenance and care

Every 6 months, check product from the outside for leakage and function.

Clean product regularly. The permissible cleaning agent is soap suds.

9

Disassembly

Warning

Risk of injury from combustion and chemical burns.

The media in the piping system and the valve can be hot and under pressure.

Medium residues can be in the product and escape when open or dismantled.

Allow the valve and piping to cool and depressurize them.

Wear specified protective equipment.

Note

Disassembly of the valve only by qualified specialized personnel.

1. De-pressurise the piping.

2. Allow the valve and pipeline to cool.

3. Empty the piping and valve completely.

– Make sure no one is located in front of the outlet opening.

– Catch discharging media in a suitable container.

4. Disconnect the piping connections and remove the valve.

10

Disposal

Observe the local specifications for environmentally friendly disposal.

Dispose of the product in an environmentally friendly manner. When doing this,

also take residual media into account (potential recycling of hazardous waste).

11

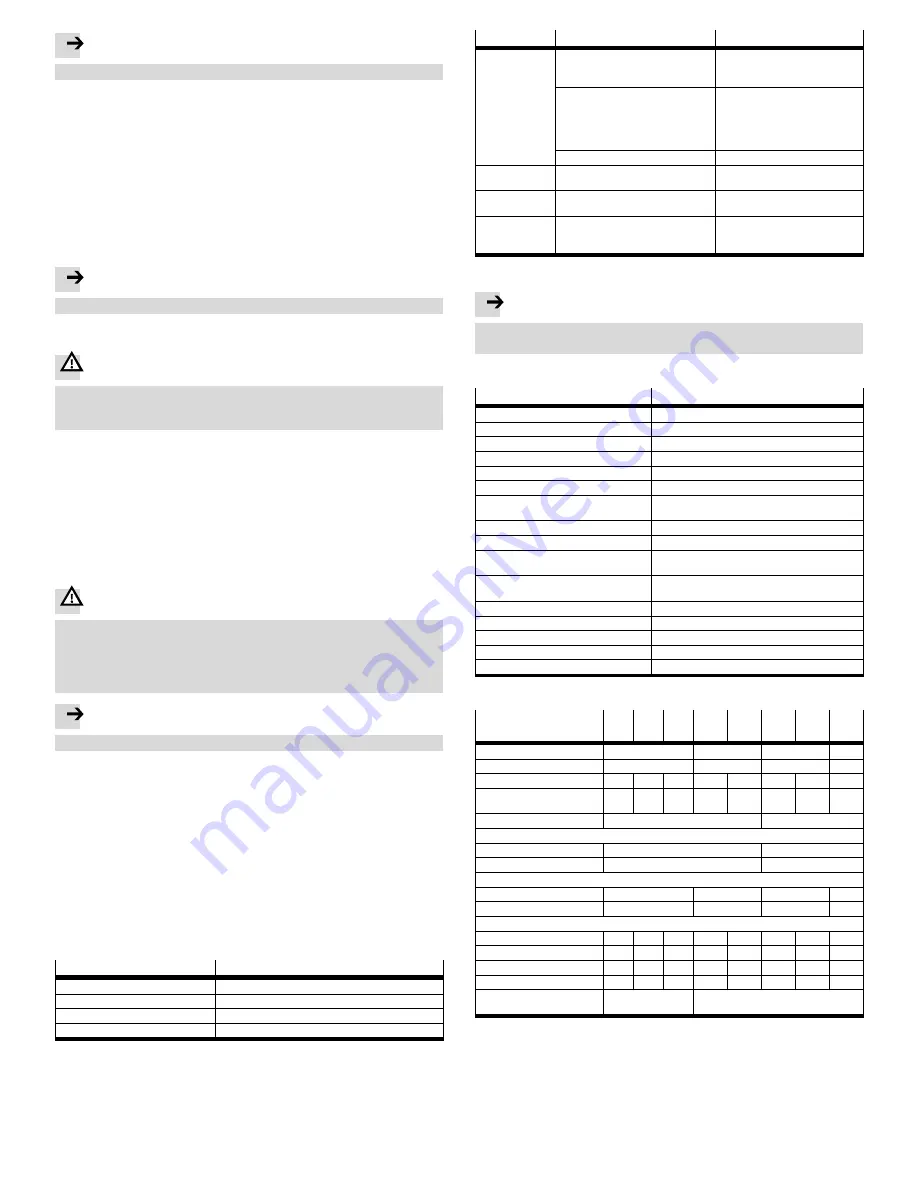

Accessories

Accessories

è

www.festo.com/catalogue

Designation

Type

Fastening bracket

HRM

Plug socket

MSSD-N

Solenoid coils for VZWM-...-F4

MD-2-24VDC-PA, MD-2-110VAC-PA, MD-2-230VAC-PA

Solenoid coils for VZWM-...-F5

MH-2-24VDC-PA, MH-2-110VAC-PA, MH-2-230VAC-PA

Fig. 6

12

Fault clearance

Malfunction

Possible cause

Remedy

Solenoid valve vi

brates or does

not switch

Differential pressure too low

Check application parameters

Increase differential pressure

between input and output.

Flow resistance at the output too low

Check piping cross sections and

line lengths.

If necessary, install flow-redu

cing components on the output

side (elbows, etc.).

Exhaust hole in the output covered

Uncover disassembly hole.

Solenoid valve

does not switch

Valve defective

Replace valve.

Solenoid valve

does not switch

Solenoid coil defective

Check solenoid coil and replace,

if necessary.

Loud switching

noises

High pressure surge

Select larger valve and pipe dia

meter.

Insert bypass valve.

Fig. 7

Note

Adjusting screw

7

may only be adjusted in consultation with Festo professional

personnel.

13

Technical data

General

VZWM

Valve function

2/2, closed monostable

Design

Poppet valve with diaphragm seal, servo controlled

Actuation type

Electrical

Sealing principle

Soft

Type of mounting

In-line installation

Mounting position

Preferably vertical

Medium

Compressed air in accordance with ISO 8573-1:2010

[7:4:4], Inert gases, Water, Neutral liquids

Direction of flow

Non-reversible

Max. viscosity

[mm

2

/s]

22

Temperature of medium gaseous

media

[°C]

–10 …+60

Temperature of medium liquid me

dia

[°C]

+5 …+50

Ambient temperature

[°C]

–10 …+60

Note on materials

Contains materials with PWIS

Materials information for housing

Brass, Stainless steel casting (-R1)

Materials information for seals

NBR

Materials information for armature tube

High-alloy steel

Fig. 8

Characteristics

VZWM-...

G14

N14

G38

N38

G12

N12

G34

N34

G1

N1

G114

N114

G112

N112

G2

N2

Nominal diameter

[mm] 13.5

27.5

40.0

50.0

Nominal diameter (-R1)

[mm] 13.0

25.0

40.0

50.0

Flow factor K

v

[m

3

/h]

1.6

2.0

2.4

8.5

10.7

21.3

27.4

39.0

Standard nominal

flow rate

[l/min]

1400

2100

2400

10000

11700

24000

26400

31000

Differential pressure

[bar]

0.5

0.7

Medium pressure

Gaseous media

[bar]

0.5…6

0.7…10

Liquid media

[bar]

0.5…6

0.7…6

Switching times air

On

[ms]

8

15

26

62

Off

[ms]

10

12

20

21

Switching times liquid media

On

[ms]

100

110

110

400

400

1400

1400

2100

On (-R1)

[ms]

80

110

110

420

300

1400

1400

2100

Off

[ms]

200

210

220

930

930

1900

2000

2800

Off (-R1)

[ms]

210

190

200

950

950

1900

2000

2800

CE marking

1)

No

In accordance with EU pressure equip

ment directive

1)

Declaration of conformity

è

www.festo.com/sp

2)

Switching time adjustable through the regulating screw

Fig. 9