Connect lines

1. Bring the solenoid valve into its installation position. Please note the direction of

flow. The permissible flow direction is marked by an arrow on the valve body. In

vacuum mode, connect up vacuum at output end.

2. Screw the valve plugs into the pipeline ends. Comply with the permissible tight

ening torques (

è

Fig. 6).

3. Establish the electrical connection. For this purpose use only the associated

socket type (

è

Fig. 7).

– Connect electrical cables to the socket.

– Attach seal to the electrical contacts.

– Put on plug and lock with fastening screw (tightening torque 0.3…0.5 Nm).

4. Connect the power supply.

7

Commissioning

Note

Commissioning only by qualified specialist personnel.

When incompressible media are used (e.g. neutral water) pressure surges arise

in the piping system because of the switching of the valve. Before commission

ing, check the compatibility of the devices in the system in order to avoid dam

age to them. If necessary adjust your application parameters.

Note the information on the rating plate.

Operate the solenoid coils only with upstream fuses.

Only start up the solenoid valve when it is fully installed and fitted.

Check the connection points for tightness

Before commissioning, check that the operating conditions and permissible limit

values have been observed (

è

Technical Data).

8

Operation

Warning

Risk of injury due to hot surface!

The valve can become hot while in operation.

Do not touch the valve during operation or immediately afterward.

Comply with the operating conditions.

Always observe the permissible limit values.

9

Maintenance and care

Every 6 months, check product from the outside for leakage and function.

Clean product regularly. The permissible cleaning agent is soap suds.

10

Disassembly

Warning

Risk of injury from combustion and chemical burns.

The media in the piping system and the valve can be hot and under pressure.

Medium residues can be in the product and escape when open or dismantled.

Allow the valve and piping to cool and depressurize them.

Wear specified protective equipment.

Note

Disassembly of the valve only by qualified specialized personnel.

1. De-pressurize the pipeline.

2. Switch off the power supply.

3. Empty the pipeline and valve completely.

– Ensure that no one is in front of the outlet opening.

– Catch discharging media in a suitable container.

4. Remove the solenoid valve from the pipeline (electrical socket connection,

mounting bracket and screws).

Replacement of the solenoid coil

In the case of repair, the solenoid coil can be replaced.

Dismantling:

1. Switch off the power supply.

2. Disconnect the electrical socket connection.

3. Leave the solenoid valve and solenoid coil to cool.

4. Loosen the retaining nut and take the magnetic coil and the O-ring from the

armature guiding tube.

Mounting:

1. Push the O-ring, the solenoid coil and the elements of the particular mounting

kit above the armature guiding tube.

2. Tighten the retaining nut (tightening torque

è

Technical Data).

11

Troubleshooting

Malfunction

Possible cause

Remedy

Solenoid valve

does not close

Solenoid valve faulty.

Replace solenoid valve.

Wrong mounting position or flow direction.

Correct mounting position.

Nominal voltage still applied.

Check electrical connection.

Solenoid valve

does not open

Solenoid coil or solenoid valve faulty.

Replace solenoid coil.

Replace solenoid valve.

Nominal voltage is interrupted or

insufficient.

Check voltage.

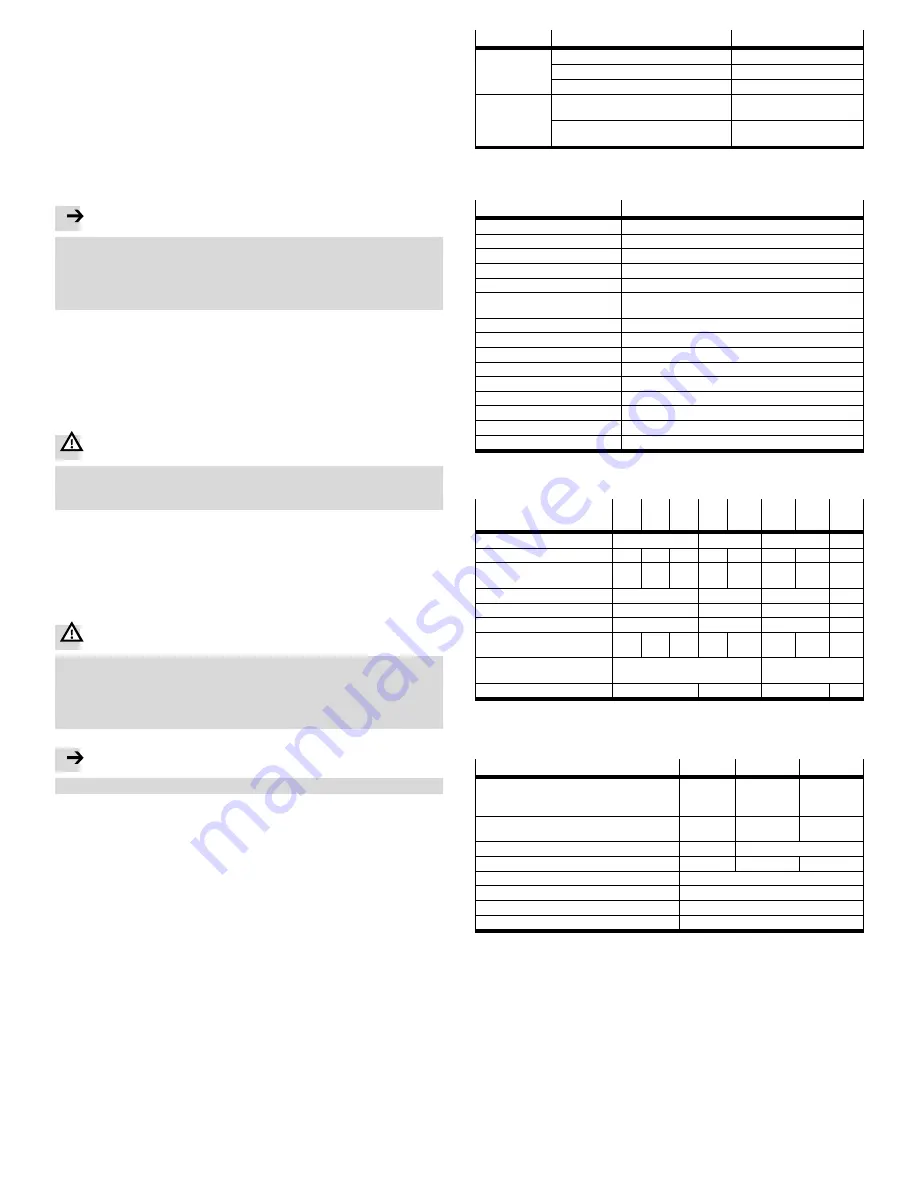

Fig. 4

12

Technical data

General

VZWF

Valve function

2/2-way valve, single solenoid, closed

Design

Diaphragm valve, forced

Actuation type

Electrical

Sealing principle

Soft

Assembly position

Magnet standing

Medium

Compressed air in accordance with ISO 8573-1:2010 [7:-:-],

Inert gases, Water, Neutral liquids

1)

Direction of flow

Non-reversible

Max. viscosity

[mm

2

/s]

22

Grade of filtration

[μm]

50

Temperature of medium

[°C]

–10...+80

Ambient temperature

[°C]

–10...+35

Protection class

IP65

Note on material for housing

Brass casting (standard), Stainless steel casting

Note on material for seals

NBR, EPDM, FPM

Note on materials for screws

High-alloy stainless steel

1)

Other media on request

Fig. 5

Connecting thread

G

¼

N

¼

G

y

N

y

G

½

N

½

G

¾

N

¾

G1

N1

G1¼

N1¼

G1

½

N1

½

G2

N2

Nominal diameter

[mm]

13.5

27.5

40

50

Flow factor K

v

[m

3

/ h]

1.8

2.2

2.5

7.5

11.0

20.0

22.5

28.0

Standard nominal flow

rate

[l/min]

1920

2350

2660

8020

11750

21370

23500

29900

Medium pressure

1)

[bar]

0…10

0…6

0…10

0…6

Switching times air on

2)

[ms]

130

275

620

1220

Switching times air off

2)

[ms]

180

290

1140

2140

Max. tightening torque

pipe connection

[Nm]

35

60

105

200

350

450

540

620

Max. tightening torque

coil fastening

[Nm]

2.0

4.0

Weight

[kg]

1.0

1.5

4.5

6.5

1)

Vacuum operation with p

abs

> 100 mbar possible

2)

Longer switching times with liquid media dependent on the viscosity

Fig. 6

Electrical data

VZWF-...1

VZWF-...2A

VZWF-...3A

Nominal voltage

– Direct current

– Alternating current (50/60 Hz)

[V DC]

[V AC]

24 (

_

10%)

–

–

110 (

_

10%)

–

230 (

_

10%)

Rated output for solenoid coil VACS-H1P

[W]

[VA]

11

–

–

19 / 16

1)

–

18 / 15

1)

Rated output for solenoid coil VACS-G2P

[W]

30

30

2)

Surge voltage capacity

[kV]

–

2.5

4.0

Duty cycle

[%]

100

Electrical connection

Device plug as per EN 175301-803, Form A

Connecting cable cross section

[mm

2]

0.75…1.5

Connection cable diameter

[mm]

5…9

1)

Switching power / holding capacity

2)

Operation with rectifier plug

Fig. 7