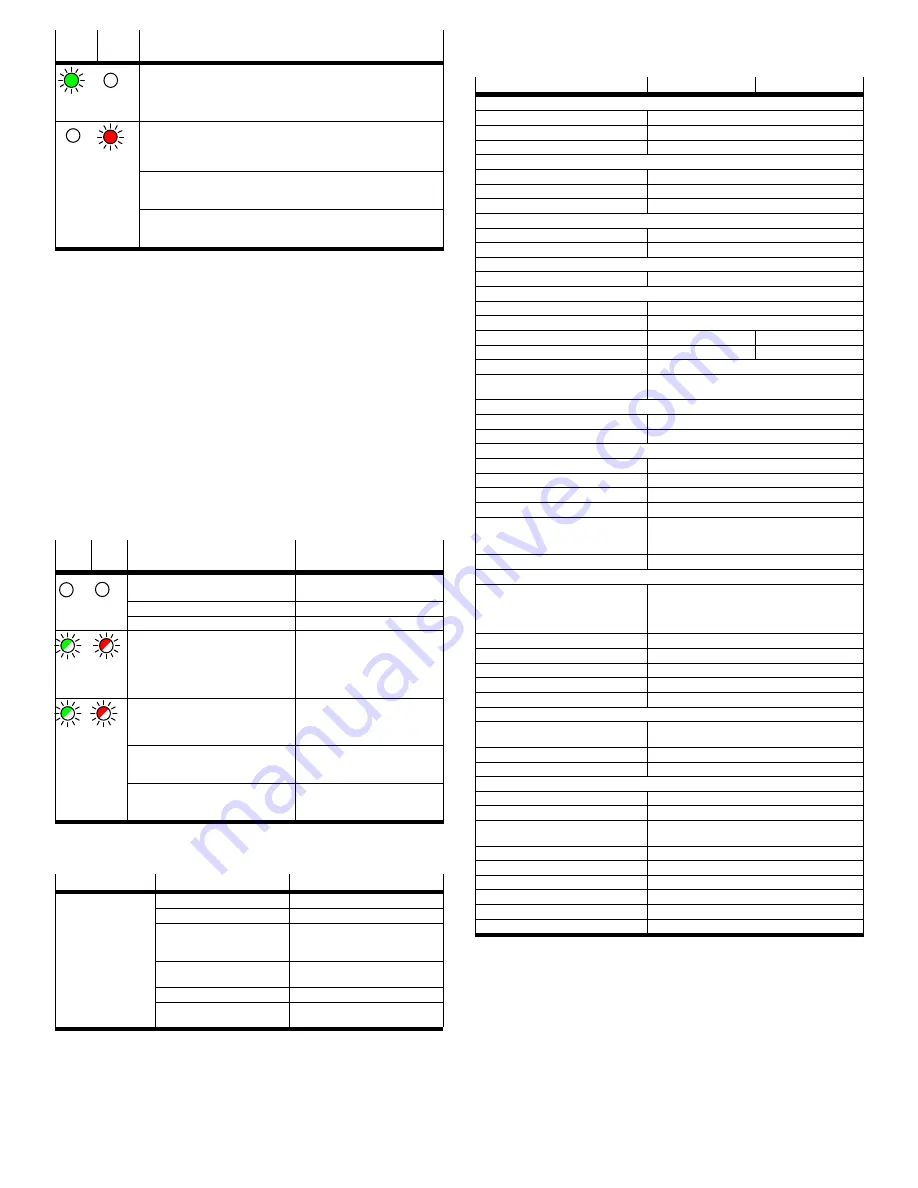

LED displays during operation

LED

Green

LED

Red

Description

Analogue signal >1 V… <10 V:

The piston is inside the measuring range (range B,

è

Fig. 10).

LED Green on,

LED Red off.

Analogue signal 0.5 V:

The piston is outside the measuring range (range A or C,

è

Fig. 10) when

operating voltage is switched on. The SMAT-8M cannot detect the piston's

position.

LED Green off,

LED Red on.

Analogue signal1 V:

The piston has exited the measuring range in the negative direction

1)

(rangeA,

è

Fig. 10). The SMAT-8M can detect the piston's position.

Analogue signal10 V:

The piston has exited the measuring range in the positive direction

2)

(rangeC,

è

Fig. 10). The SMAT-8M can detect the piston's position.

1)

The output voltage falls in the negative direction. The piston moves away from the piston rod.

2)

The output voltage rises in the positive direction. The piston moves towards the piston rod.

Fig. 11

7

Maintenance and care

Cleaning the outside of the SMAT-8M

1. Switch off the operating voltage.

2. Clean the outside of the SMAT-8M with a soft cloth.

Permissible cleaning agents are soapy water (max. +60 °C) and all non-abrasive

agents.

8

Disassembly

1. Switch off the operating voltage.

2. Disconnect the connecting cable from the SMAT-8M.

3. Undo the mounting screw on the SMAT-8M.

4. Remove the SMAT-8M from the slot.

9

Troubleshooting

9.1 Diagnostics via LED

LED

Green

LED

Red

Possible cause

Remedy

Faulty power supply.

Ensure the power supply

(

è

Fig. 4).

Both LEDs off.

Faulty connecting cable.

Replace the connecting cable.

Sensor defective.

Replace SMAT-8M.

Internal error.

Contact your local Festo Service or

[email protected].

LEDs flashing

alternately.

No valid signal.

SMAT-8M not initialised.

Initialise SMAT-8M (

è

chapter 5.2).

LEDs flashing at

the same time.

Power failure during initialisation.

Ensure the power supply and

re-initialise the SMAT-8M

(

è

chapter 5.2).

The magnetic field of the piston/gripper

was not detected correctly by the

SMAT-8M.

Initialise SMAT-8M (

è

chapter 5.2).

Fig. 12

9.2 General malfunctions

Malfunction

Possible cause

Remedy

Incorrect or unexpec

ted signals at the ana

logue output.

Unsuitable drive.

Use suitable drives only.

SMAT-8M defective

Replace SMAT-8M.

No power supply or there is a

non-permissible operating

voltage

Switch on power supply / maintain

permitted operating voltage range

Short circuit or overload at the

output

Remedy short circuit / overload.

Faulty connecting cable.

Replace the connecting cable.

Magnetic object in close prox

imity to position transmitter.

Prevent magnetic objects being in

close proximity.

Fig. 13

10

Accessories

Accessories

è

www.festo.com/catalogue/SMAT-8M.

11

technical data

technical data

Cylinder

Grippers

General

Certification

RCM Mark, c UL us - Listed (OL)

CE marking (

è

declaration of conformity)

In accordance with EU EMC Directive

Note on materials

Conforms to RoHS

Input signal/measuring element

Measured variable

Item

Measuring principle

Magnetic

Measuring range

1)

[mm]

≤ 40

Signal processing

Max. travel speed

[m/s]

3

Typical sampling interval

[ms]

2.8

Output, general

Range resolution

2)

[mm]

≤ 0.05

Analogue output

Analogue output

[V]

0 … 10

Sensitivity

1)

[mm/V]

Measuring range/9 V

Linearity error, typ.

1)

[±mm]

1

0.2

Repetition accuracy

[±mm]

0.1

0.025

Capacitive load max. DC

[nF]

100

Min. load resistance

Voltage output

3)

[kΩ]

2

Output, additional data

Protection against short circuit

Yes

Protection against overloading

Yes

Electronic components

Rated operating voltage DC

[V]

24

Operating voltage DC

[V]

15 … 30

Idle current

[mA]

15 (V

oper

= 24 V)

Ready-state delay

[ms]

≤ 300

Signal run time, typ.

1) 4)

[ms]

14 at v < 0.016 m/s

8.5 at 0.016 < v < 0.05 m/s

5.5 at v > 0.05 m/s

Reverse polarity protection

For all electrical connections

Electromechanical components

Cable test conditions

Energy chain 50 000 cycles, bending radius 30 mm

Torsional strength min. 300 000 cycles, ±270°/0.1 m

Bending strength according to Festo standard, test

conditions upon request

Cable length

[m]

0.3

Max. connecting cable length

[m]

30

Electrical connection

Cable with plug, M8x1, rotatable thread, 4-pin

Pin contact materials

Gold-plated brass

Cable sheath materials

TPE-U (PU)

Mechanical components

Type of mounting

Screw-type union, for insertion into slot from above,

max. torque 0.6 Nm

Housing materials

Reinforced PA6

Union nut materials

Nickel-plated brass

Immission/emission

Storage temperature

[°C]

–25 … +75

Ambient temperature

[°C]

–25 … +75

Ambient temperature with flex

ible cable installation

[°C]

–5 … +70

Recovery time

[ms]

< 2.8 as per DIN 60947-5-7

IP protection (as per EN 60529)

IP65/IP68 (IP68 condition: test duration 24 hrs)

Protection class (as per DIN VDE 0106-1)

III

Resistance to shocks (as per EN 60068-2)

Severity level 2

Vibration resistance (as per EN 60068-2)

Severity level 3

Corrosion resistance class CRC

2

1)

Varies depending on the drive used.

2)

Range resolution = working range/921 (e.g. 0.027 mm for 25 mm working range).

3)

Recommended: connect a resistor to the analogue output, typically 10 kΩ.

4)

The signal run time is longer than the scanning interval because of the dynamic filtering. There are three

velocity-dependent filter stages. The examples are valid for a working range of 20 mm.