ESBF-BS/-LS

Electric cylinder

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Deutschland

+49 711 347-0

www.festo.com

Operating instructions

8155148

2021-04d

[8155150]

Translation of the original instructions

© 2021 all rights reserved to Festo SE & Co. KG

1

Applicable Documents

All available documents for the product

2

Safety

2.1

Safety instructions

–

Observe labelling on the product.

–

Prior to assembly, installation and maintenance work: Switch off power supply,

ensure that it is off and secure it against being switched back on.

–

Store the product in a cool, dry, UV-protected and corrosion-protected environ-

ment. Ensure that storage times are kept to a minimum.

–

Observe tightening torques. Unless otherwise specified, the tolerance

is ± 20 %.

2.2

Intended Use

The electric cylinder is intended to be used for positioning payloads in combina-

tion with tools or as a drive when external guides are used.

2.3

Training of qualified personnel

Work on the product may only be carried out by qualified personnel who can

evaluate the work and detect dangers. The qualified personnel have knowledge

and experience in handling electric drives and axes.

3

Additional information

–

Contact the regional Festo contact if you have technical problems

–

Accessories and spare parts

4

Product overview

4.1

Function

The electric cylinder converts the rotary motion of the mounted motor into a linear

motion of the non-rotating piston rod. The lead screw converts the torque of the

motor into a feed force. The linear movement of the piston rod is precisely guided

by the guide in the bearing cap. Sensors enable the monitoring of end positions,

reference position and intermediate position.

Lead screw ESBF-LS

Ball screw drive ESBF-BS

–

Low speeds

–

Self-braking with de-energised motor (without

brake)

–

High speeds

–

High forces

Tab. 1: Overview of Lead Screw

4.2

Product design

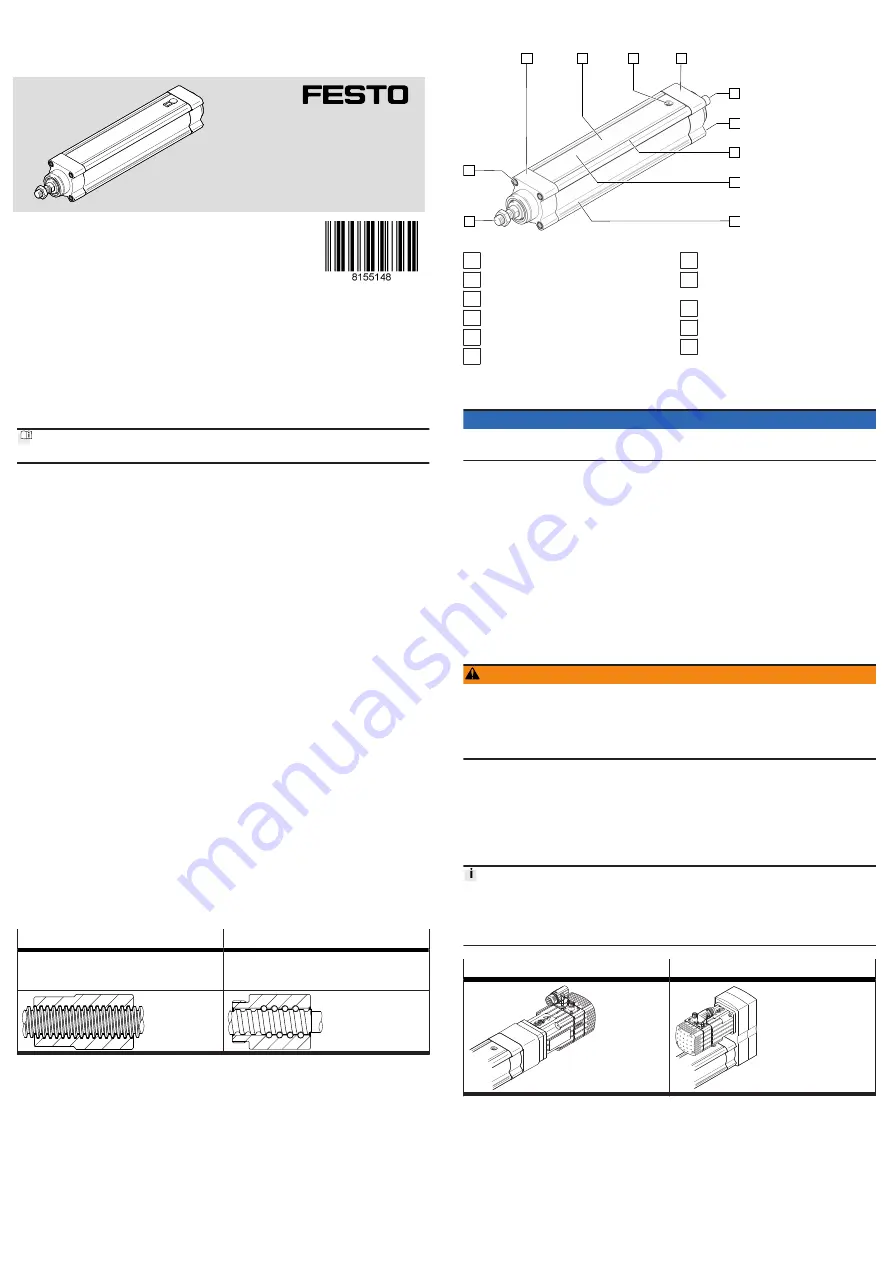

ESBF product design

1

2

3

4

5

6

7

8

9

10

11

Fig. 1: ESBF product design (example ESBF-BS)

1 Piston rod

2 Threaded hole for mounting

3 Bearing cap

4 Cylinder profile

5 Pressure compensation port

6 Drive cover

7 Drive shaft

8 Threaded hole for motor

mounting kit

9 Interface for sensor bracket

10 Interface for sensor rail

11 Interface for profile mounting

5

Transport and Storage

NOTICE

Unexpected and unbraked movement of components

• Secure moving components for transport.

Transport and Storage Conditions

–

Take product weight into account

Weight > 25 kg: transport with a suitable hoist (cross-brace) or with two per-

sons.

–

Take the product focus into consideration.

–

Store and transport the product in its original packaging.

–

Store product in a cool, dry, shaded and corrosion protected environment.

–

Store product in ambient conditions without oils, greases and degreasing

vapours.

–

Ensure short storage times.

6

Assembly

6.1

Safety

WARNING

Risk of Injury due to Unexpected Movement of Components

For vertical or slanted mounting position: when power is off, moving parts can

travel or fall uncontrolled into the lower end position.

• Bring moving parts of the product into a safe end position or secure them

against falling.

6.2

Unpacking

1. Open packaging.

2. Remove all transport materials (e.g. foils, caps, cardboard boxes).

3. Remove the product from the packaging and place it on the mounting surface.

4. Dispose of packaging and transport materials.

6.3

Mounting the motor

Transverse load on the drive shaft

When mounting the motor and motor mounting kit, do not exceed the maximum

transverse load F

R

of the drive shaft (for example toothed belt tension when

mounting the parallel kit)

Axial kit EAMM-A

Parallel kit EAMM-U

Tab. 2: Overview of motor mountings

Requirement

–

Only loosen screws or threaded pins that are described in the directions in the

instruction manuals.

–

Sufficient space for reaching and mounting the pressure compensation port

Connecting pressure compensation (ESBF -...- S1 only).

1. Select the motor and motor mounting kit from

Festo

If other motors are used: observe the critical limits for forces, torques and

velocities.