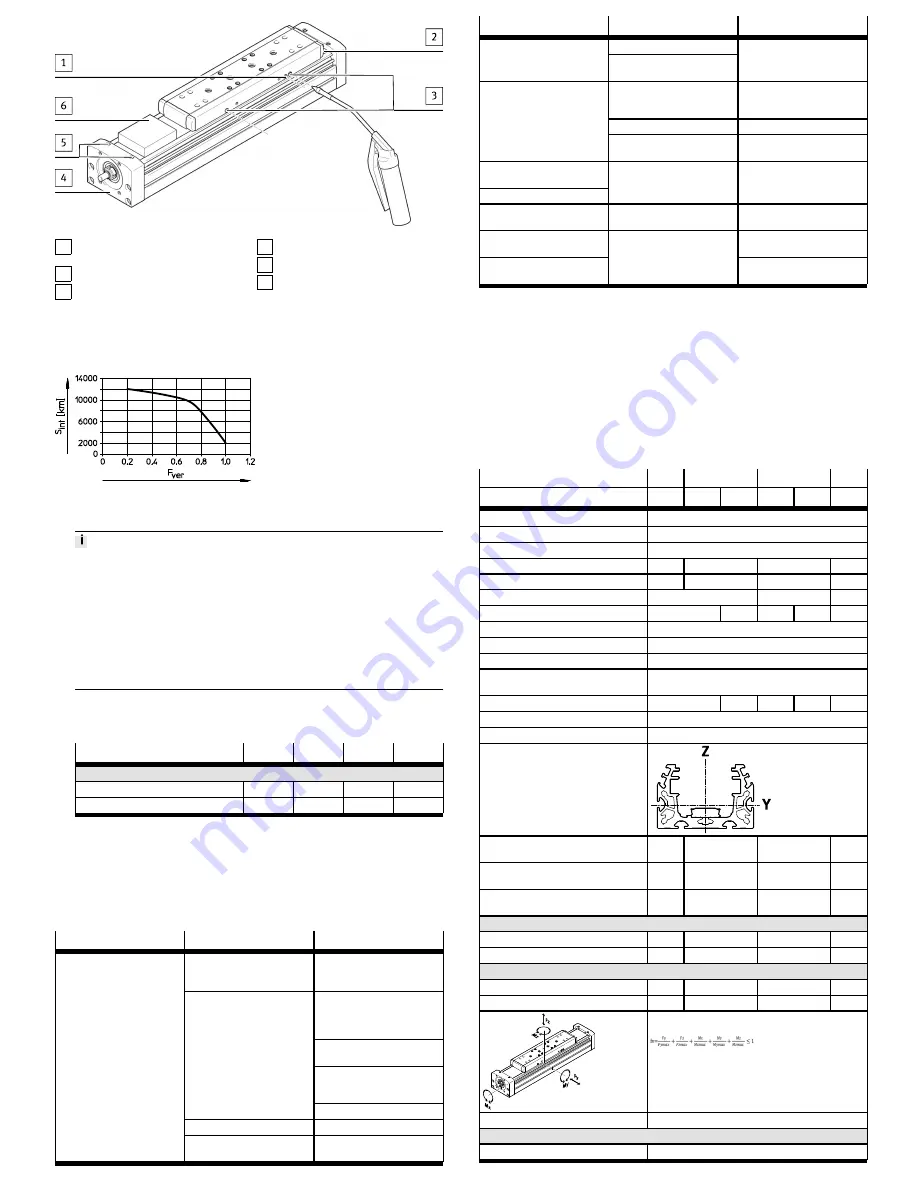

1 Relubrication opening of the ball

screw

2 Cover strip

3 Relubrication openings of the

guide

4 Cover

5 Screws

6 Clamping element

Fig. 15 Lubricating the ball screw and guide

1. Calculate load comparison factor f

v

with the help of the formula for combined

loads

è

9 Technical data: mechanical.

Fig. 16 Lubrication interval

2. Read off lubrication interval S

int

è

Fig.16.

The lubrication interval S

int

is dependent on the load acting on the product.

Load factors:

•

Dusty and dirty environment

•

Nominal stroke

>

2000 mm or

<

300 mm

•

Travel profile

Z

triangular operation (frequent acceleration and braking)

•

Ambient temperature

>

+ 40 °C

•

Age of the product

>

3 years

If one of these factors applies, halve the lubrication interval S

int

.

If several factors apply at the same time, reduce the lubrication interval S

int

by

three-quarters.

3. Lubricate the guide and ball screw at all relubrication openings

è

Fig.15.

Accessories and permitted lubricants

è

3.1 Not included in the delivery.

Amount of lubricant at each relubrication opening:

Size

70

80

120

150

Amount of lubricant

Ball screw

[g]

2

2.5

3

15

Guide

[g]

0.4

0.8

2.0

3.4

Tab. 7 Amount of lubricant

7.1

Cleaning and maintenance

•

Clean the spindle axis with a soft cloth as required. Cleaning agents include

all non-abrasive media.

8

Malfunctions

8.1

Fault clearance

Malfunction

Possible cause

Remedy

Coupling distance incorrect

Observe the permissible coup-

ling spacings

è

www.festo.com/sp.

Install the axis so it is free of

tension; maintain evenness of

the bearing surface

è

5.1 Mechanical installation.

Change arrangement of the

tool/payload.

Align the spindle axis so that it

is exactly parallel to the second

spindle axis.

Tensions

Change the travel speed

Controller is incorrectly set

Changing the parameters

Squeaking noises, vibrations or

the axis is not running

smoothly.

Insufficient lubrication at guide. Lubricate the spindle axis

è

7 Maintenance.

Malfunction

Possible cause

Remedy

Guide defective

Squeaking noises, vibrations or

the axis is not running

smoothly.

Guide or cover strip reversal

devices worn

Send spindle axis to Festo or

contact the local Festo service.

Coupling spins.

Check the assembly of the

motor mounting kit

è

www.festo.com/sp.

Load levels are too high.

Reduce load mass/torques.

Slide does not move.

Retaining screws on tool are

too long.

Observe the maximum screw-in

depth

è

Mounting attachments

The reversing backlash is too

large

è

7 Maintenance

The idling torque increases.

Wear

Return spindle axis to Festo for

repair

è

8.2 Repair.

Slide travels over end position.

Proximity sensors do not oper-

ate

Check proximity sensor, con-

nections and controller.

Cover strip has waves.

Retension cover strip

è

7 Maintenance

Aluminium wear on spindle

axis.

Wear on belt reversal device.

Replace the belt reversal device

è

www.festo.com/spareparts.

Tab. 8 Fault clearance

8.2

Repair

•

Remove motor cables and mounting components.

If repairs are required:

–

Send the spindle axis to the Festo repair service.

–

Information about spare parts and accessories

è

www.festo.com/spareparts.

8.3

Disposal

Dispose of the packaging and the axis at the end of its useful life through environ-

mentally friendly recycling in accordance with applicable specifications.

9

Technical data: mechanical

Size

1)

70

80

120

150

Spindle pitch

10

10

20

10

25

40

Design

Electromechanical axis with ball screw

Guide

Recirculating ball bearing guide

Mounting position

Any

Max. feed force F

v

[N]

650

1600

3400

6400

Max. no-load driving torque

2)

[Nm]

0.45

0.75

2.25

6.5

Maximum speed

[1/min]

3000

3600

3000

Max. speed

[m/s]

0.5

1

0.6

1.5

2

Max. acceleration

[m/s

2

]

15

Repetition accuracy

[mm]

± 0.02

Reversing backlash (new)

[mm]

<

0.01

Reversing backlash (limit

value)

è

7 Maintenance

Feed constant

[mm/U]

10

20

10

25

40

Ambient temperature

[°C]

–10 … +60

Degree of protection

IP40

2nd degree of surface torque

l

y

[mm

4

]

165 x -

10

3

310 x 10

3

1.24 x 10

6

4.70 x-

10

6

l

z

[mm

4

]

472 x -

10

3

977 x 10

3

3.80 x 10

6

11.81 -

x 10

6

Max. radial force on drive

shaft

[N]

220

250

500

4000

Maximum permissible forces on the slide

F

y

[N]

1500

2500

5500

5500

F

z

[N]

1850

3050

6890

11000

Maximum permissible torques on the slide

M

x

[Nm]

16

36

104

167

M

y

= M

z

[Nm]

132

228

680

1150

Determination of the load compensation factor for com-

bined loads:

Information on materials

Contains paint-wetting impairment substances

Materials

Cover, profile, slide

Anodised aluminium