S.p.A.

8

SUN

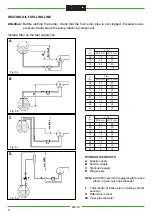

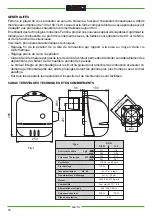

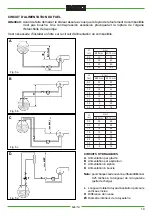

CHOOSING THE INJECTOR

The injector must be chosen according to the power rating of the boiler flue, remembering that heating

oil has a heat value (N.H.V.) of 10200 kcal/Kg. The chart gives the flow rate or consumption in Kg/h and

kW of heating oil according to the size of the injector (in GPH) and the pump pressure (in bar). When the

burner has a preheater, the effective capacity will be about 10% lower than the values in the chart.

Injector

G.P.H.

0,40

0,50

0,60

0,65

0,75

0,85

1,00

1,10

1,20

1,25

1,35

1,50

1,65

1,75

2,00

2,25

2,50

3,00

1,27

1,59

1,91

2,07

2,38

2,70

3,18

3,50

3,82

3,97

4,29

4,77

5,25

5,56

6,30

7,15

7,95

9,54

7

1,36

1,70

2,04

2,21

2,55

2,89

3,40

3,74

4,08

4,25

4,59

5,10

5,61

5,95

6,80

7,65

8,50

10,20

8

9

1,44

1,80

2,16

2,34

2,70

3,06

3,61

3,97

4,33

4,50

4,87

5,41

5,95

6,31

7,21

8,15

9,01

10,82

1,52

1 ,90

2,28

2,47

2,85

3,23

3,80

4,18

4,56

4,75

5,13

5,70

6,27

6,65

7,60

8,55

9,50

11,40

10

1,59

1,99

2,39

2,59

2,99

3,39

3,99

4,38

4,78

5,00

5,38

5,90

6,58

6,98

7,97

8,97

9,97

11,96

11

1,67

2,08

2,50

2,71

3,12

3,54

4,16

4,58

5,00

5,20

5,62

6,24

6,87

7,29

8,33

9,37

10,41

12,49

12

1,73

2,17

2,60

2,82

3,25

3,68

4,33

4,77

5,20

5,40

5,85

6,50

7,15

7,58

8,67

9,75

10,83

13,00

13

1,80

2,25

2,70

2,92

3,37

3,82

4,50

4,95

5,40

5,60

6,07

6,75

7,42

7,87

8,99

10,12

11,24

13,49

14

1,86

2,33

2,79

3,03

3,49

3,96

4,65

5,12

5,59

5,80

6,28

6,98

7,68

8,15

9,31

10,47

11,64

13,96

15

17

1,98

2,48

2,97

3,22

3,72

4,21

4,96

5,45

5,95

6,20

6,69

7,43

8,18

8,67

9,91

11,15

12,39

14,87

16

1,92

2,40

2,88

3,12

3,61

4,09

4,81

5,29

5,77

6,00

6,49

7,21

7,93

8,41

9,61

10,85

12,02

14,42

6

1,18

1,47

1,77

1,91

2,2

2,5

2,94

3,24

3,53

3,68

3,97

4,42

4,86

5,15

5,89

6,62

7,36

8,83

Pump pressure kg/cm

2

Flow rate at injector outlet kg/h