MODENA S HE

14

EN

cod. 3541C364 - Rev. 00 - 12/2012

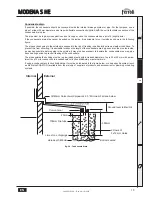

2.6 Flue system

This unit is a "C type" with

sealed chamber

and forced draught, with air inlet and flue exhaust to be connected to one

of the following flue systems. Before installation, with the aid of the tables and calculation methods given, check that the

pipes of the fume system do not exceed the maximum permissible lengths. The current standards and local regulations

must be observed.

B

Only a Ferroli flue system (with respective accessories) must be used with this unit, as required by BS 5440

and CE standards.

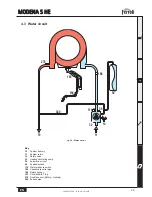

Connection with coaxial pipes

Standard connection with coaxial pipes (code 041049G0)

fig. 17 - Standard connection

Horizontal flue installation

1. Define the position for installing the unit.

2. If using standard flue (

041049G0

) this must be installed level. For extended horizontal flue lengths over 1m a fall of

3 mm per metre of the flue exhaust should be incorporated back to the boiler.

3. Make a hole of diameter 10 - 20 mm greater than the nominal diameter of the concentric pipe used.

4. If necessary, cut the terminal length to size, ensuring that the external pipe protrudes from the wall by between 10

and 60 mm. Remove the cutting burrs.

5. Connect flue to the boiler, positioning the seals correctly. Seal the flue into the wall with silicone or sand + cement

and cover with wall seals provided.

A

Flue seals should be lubricated with a silicone type grease to prevent damage (grease not supplied).

Between

10 e 60 mm

Between

10 e 60 mm

320

125

200

80

600

Ø100

125

110

80

600

Ø100

Drill the wall 10÷20 mm

more than the

pipe diameter

Rear outlet

Side view

Side outlet

Front view

200

400