6

Ferm

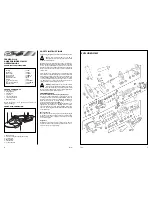

SPARE PARTS LIST FAG-230

REF NR

DESCRIPTION

FERM NR

03

WOOD RUFF KEY

407920

04

FLANGE OUTSIDE

406847

06

FLANGE INSIDE

406846

07

PROTECTING GUARD

407929

16

SPINDLE GEAR

407921

23

PINION GEAR

407922

32

ROTOR

407923

37

STATOR

407928

39

CARBON BRUSH COVER

407924

41

CARBON BRUSH

407925

42

CARBON BRUSH HOLDER

407926

45

SWITCH

407927

47

CAM WRENCH

406814

48

SIDE HANDLE

406277

Ferm

3

OPERATIONAL SAFETY

Warning!

Never use the machine for grinding magnesium

workpieces. Use fibre reinforced discs only.

Do not use near flammable materials or people. Do not use

the machine to grind/cut deeper than the maximum grinding

depth of the disc. Do not use grinding discs for deburring.

Concentrate

Routine and repetition can lead to mistakes. Remember

that a slight lack of concentration can result in serious

injuries in a split second.

Keep work area clean

Cluttered areas and benches invite injuries.

Consider the work environment

Do not expose power tools to rain or use them in damp

or wet locations. Keep work area well lit. Do not use

power tools in the presence of flammable liquids, vap-

ours or gases.

Guard against electric shock

This unit contains dangerous voltages. Use a RCD (resi-

dual current device) to provide protection against elec-

trical shock. Prevent body contact with grounded sur-

faces (e.g. pipes, radiator, ranges or refrigerators).

Keep children and pets away

Do not let children or pets come into contact with the

tool, extension cable or work area.

Do not force the tool

It will work better and safer at the rate for which it was

intended

Use the right tool

Do not force small tools or attachments to do the job of a

heavy-duty tool. Do not use tools for purposes for which

they were not intended; for example do not use a circular

saw for cutting trees or logs.

Do not abuse cable

Never carry the tool by the cable or pull it to disconnect

it from the power socket. Keep the cable away from heat,

oil and sharp edges. Do not touch the metal plug pins

when connecting or removing the plug.

Secure Work

Use clamps or a vice to hold work. It is safer than using

your hand and it frees both hands to operate the tool.

Be

aware that this grinder is a powerful machine;

you must use two hands to control it.

Do not over-reach

Keep a proper footing and balance at all times.

Disconnect tools from power supply

When not in use, before servicing and when changing

accessories such as blades, bits and cutters.

Always

switch off and unplug the angle grinder from the

power supply before making adjustments or

changing grinding discs,

Remove adjusting keys and wrenches

Ensure that they are removed from the tool before swit-

ching on.

Avoid unintentional starting

Do not carry plugged in tools with your finger on the

switch. Check that the switch is off before plugging in to

socket.

Extension cables

Use only three core earthed extension cables suitable

for the power input of the tool (minimum cable size

1.5mm2). Plug into an earthed socket only.

When using a cable reel unwind it fully. Do not use long

extension cables.

Outdoors use

If the tool is suitable to be used outdoors, only use an

extension cable intended for outdoor use and marked

accordingly. Use a RCD (residual current device) to pro-

vide protection against electrical shock. Do not use in

rain or damp conditions.

Connect a dust extraction device

Whenever there are facilities for fitting a dust of fume

extraction system, make sure it is connected and used.

Use recommended accessories

The use of any other accessory or attachment other than

recommended in the instructions or catalogue may pre-

sent a risk of personal injury. Use extension cables suita-

ble for the power input of the grinder (minimum cable

size 1.5mm2). When using a cable reel unwind it fully.

ASSEMBLING THE ACCESSORIES

Do not use this machine without the guard in place.

Ensure the grinder is unplugged from mains.

TO MOUNT THE GUARD

_ Without a grinding disc in the machine, place the

guard assembly (9) over the flange; make sure the

clamp on the guard assembly is pushed onto the

flange as far as it will go.

-

Tighten the clamp screw firmly with the hexagon key

provided.

+

11

12

7

9

6

5