www.fennerdrives.com

For technical assistance,

please call +1-717-665-2421

B-LOC®

Keyless Bushings provide a high capacity, zero-backlash shaft/hub or

coupling connection by means of a mechanical interference fit. Please follow

these INSTALLATION AND REMOVAL INSTRUCTIONS carefully to ensure

proper performance of this

B-LOC

® unit.

INSTALLATION

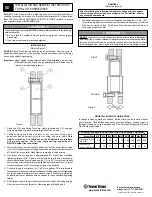

(Refer to Figure 1)

B-LOC®

Series B103 and B106 Keyless Bushings are supplied lightly oiled and

ready for installation. They are self-centering and fit straight-thru hub bores. Note

that Series B103 units permit axial hub movement during installation. In contrast,

the extended flange on Series B106 units results in an axially fixed hub position

during assembly. When reinstalling a used unit, make sure that all slits are

aligned. The frictional torque capacity of these devices is based on a coefficient

of friction of 0.12 for lightly oiled screw, taper, shaft and bore contact areas.

Therefore, it is important not to use Molybdenum Disulfide (e.g., Molykote,

Never-Seeze or similar lubricants) in any Keyless Bushing installation.

1. Make sure that locking screw, taper, shaft and bore contact areas are clean

and lightly oiled with a light machine oil and that all collar slits are aligned.

2. Loosen all locking screws by a minimum of four (4) turns and transfer at

least three (3) screws into push-off threads in order to keep Parts 1 and 2

separated during assembly (see Figure 2).

3. After inserting Keyless Bushing into hub bore, relocate locking screws used

for separating Parts 1 and 2.

4. Hand tighten locking screws and confirm that collar Item 1 is parallel and in

full contact with face of part to be attached to shaft.

5. Use torque wrench and set it approximately 5% higher than specified

tightening torque (Ma). Tighten locking screws in either a clockwise or

counterclockwise sequence (it is not necessary to tighten in a diametrically

opposite pattern), using only 1/4 (i.e., 90°) turns for several passes until 1/4

turns can no longer be achieved.

6. Continue to apply overtorque for 1 to 2 more passes. This is required to

compensate for a system-related relaxation of locking screws since tightening

of a given screw will always relax adjacent screws. Without overtorquing,

an infinite number of passes would be needed to reach specified tightening

torque.

7. Reset torque wrench to specified torque (Ma) and check all locking screws.

No screw should turn at this point, otherwise repeat Steps 6 and 7.

NOTE:

1. It is not necessary to re-check tightening torque after equipment has

been in operation.

2. The torque capacity of these units can be increased by approximately

25% by thoroughly cleaning the shaft and Keyless Bushing bore of any

lubricant. In applications subject to extreme corrosion, the slits in all

collars should be sealed with a suitable caulking compound or equivalent.

Likewise, push-off threads should be protected from corrosion.

INSTALLATION OF B-LOC® KEYLESS BUSHING

OVER SHAFT KEYWAYS

The Keyless Bushing should be positioned so that slits in Keyless Bushing

collars that contact the shaft are located approximately opposite the keyway.

In addition, a locking screw should be centered directly over the keyway.

When tightening locking screws, it is important to follow the installation

procedure outlined above, which specifies equal 1/4 turns of each locking

screw. Failure to follow these instructions could result in excessive tightening

of the screw over the keyway, possibly causing permanent deformation of

the Keyless Bushing collars.

REMOVAL

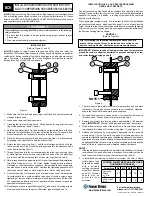

(Refer to Figure 2)

Prior to initiating the following removal procedure, check to

ensure that no torque or thrust loads are acting on the Keyless

Bushing, shaft or any mounted components.

IMPORTANT!

Make sure ends of locking screws used for removal are

ground flat and are slightly chamfered to prevent damage to screw and

collar threads during push-off.

1. C h e c k t o e n s u r e t h a t

axial movement of collars

- necessary for release of

connection - is not restricted.

Likewise, ensure that push-off

threads are in good condition.

2. Relax all locking screws by

approx. four (4) complete

turns and transfer screws to

all push-off threads located in

flange of collar Item 1.

3. Release connection by evenly

tightening all push-off screws

(not exceeding 1/4 turns)

in a diametrically opposite

sequence.

©2012 Fenner Drives B-PR-014 9/17/2012

LOCKING SCREW SIZES AND SPECIFIED

TIGHTENING TORQUE M

a

Metric Series

Inch Series

Tightening

Torque

Ma

(ft lb)

Screw

Size

Hex

Key

Size

(mm)

B106 B103

20 x 47 to 40 x 65

3/4

to 1-1/2

12

10

M6

5

45 x 75 to 65 x 95

1-5/8

to 2-9/16

30

25

M8

6

70 x 110 to 95 x 135 2-11/16 to 3-3/4

60

50

M10

8

100 x 145 to 120 x 165 3-15/16 to 4-3/4

105

90

M12

10

130 x 180 to 200 x 260 4-15/16 to 8

166

135

M14

12

220 x 285 to 260 x 325

257

219

M16

14

280 x 355 to 300 x 375

350

290

M18

14

320 x 405 to 340 x 425

500

420

M20

17

360 x 455 to 400 x 495

675

560

M22

17

INSTALLATION AND REMOVAL INSTRUCTIONS

FOR

B-LOC

®

KEYLESS BUSHING SERIES B106 & B103

B106

B103

Figure 2

WARNING

When installing or removing

B-LOC

®

products, always adhere to the following

safety standards:

1. Be sure that the system is de-energized using proper lockout/tagout

procedures.

2. Wear proper personal protective equipment.

Figure 1