- 7 -

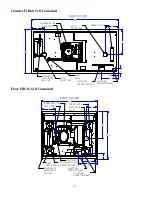

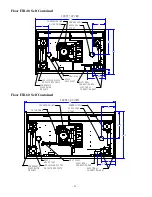

Counter Models:

FIELD CONNECTION BOX

CONDUIT OR

POWER CORD

CONNECTION .875

O

MISC ACCESS HOLE

MISC ACCESS HOLE

REAR COMPARTMENT PANELS

CONDUIT OR

POWER CORD

CONNECTION .875

O

Cord Connected (OPTION)

-A factory installed optional power cord is properly sized to the amperage requirements of the case. See the

electrical data plate located on the rear exterior of the case for the proper circuit size for each case.

- The cord is factory installed protruding from the rear corner of the case.

-A separate circuit for each display case is required to prevent other appliances on the same circuit from

overloading the circuit and causing malfunction.

CAUTION

Risk of Electric Shock. If the cord or plug becomes damaged,

replace only with a cord and plug of the same type".