9

MAINTENANCE MANUAL: MODELS 860, LF860, 860U & LF860U

1

/

2

"- 2" (15 – 50mm)

Testing

All mechanical devices should be inspected on a regular basis to ensure

they are working correctly . The assembly should be tested at time of

initial installation, after servicing or maintenance, and at least annually

thereafter . Acceptable test procedures are published by Foundation

for Cross-Connection Control and Hydraulic Research at the University

of Southern California (USC), The American Water Works Association

(AWWA), The American Society of Sanitary Engineering (ASSE Series

5000) and the Canadian Standards Association (CAN/CSA B64•10). Please

consult the regulatory authority in your area for more specific information .

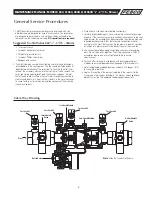

Air Gap Drain Installation Instructions

1 . Before installation check local codes . This type of drain may not be

approved for use in some areas .

CAUTION

!

This drain is intended to catch moderate relief valve

discharges due to line pressure fluctuations and minor check valve

fouling. Under certain conditions relief valves can discharge water at

rates greater than the air gap

drain capacity.

2 . If installed indoors, the assembly should be installed near a floor drain

sized to adequately handle discharge . A Strainer before the backflow

assembly is strongly suggested on indoor installation .

3 . After installation of backflow assembly and piping, attach drain funnel

to relief as shown, using self tapping screws provided in kit to join drain

funnel halves together, making sure that the slots in the drain funnel

are located over tabs on relief valve port .

NOTICE

Discharge of drain funnel is a slip fit design . Drain funnel was not

designed to, nor is it able to support drainpipe weight .

plaSTIC

MeTal

ValVe SIze

paRT nO.

paRT nO.

1

/

2

"

905358

905532

3

/

4

"

905358

905532

1"

905358

905532

1

1

/

4

"

905359

905533

1

1

/

2

"

905359

905533

2"

905359

905533

Air Gap Part Number