REBUILD INSTRUCTIONS

www.fastestinc.com

Roseville, MN

Toll Free at 1-800-444-2373

Fax 651-645-7390

PAT# 6,039,303

WP085 Rev B 04/2009

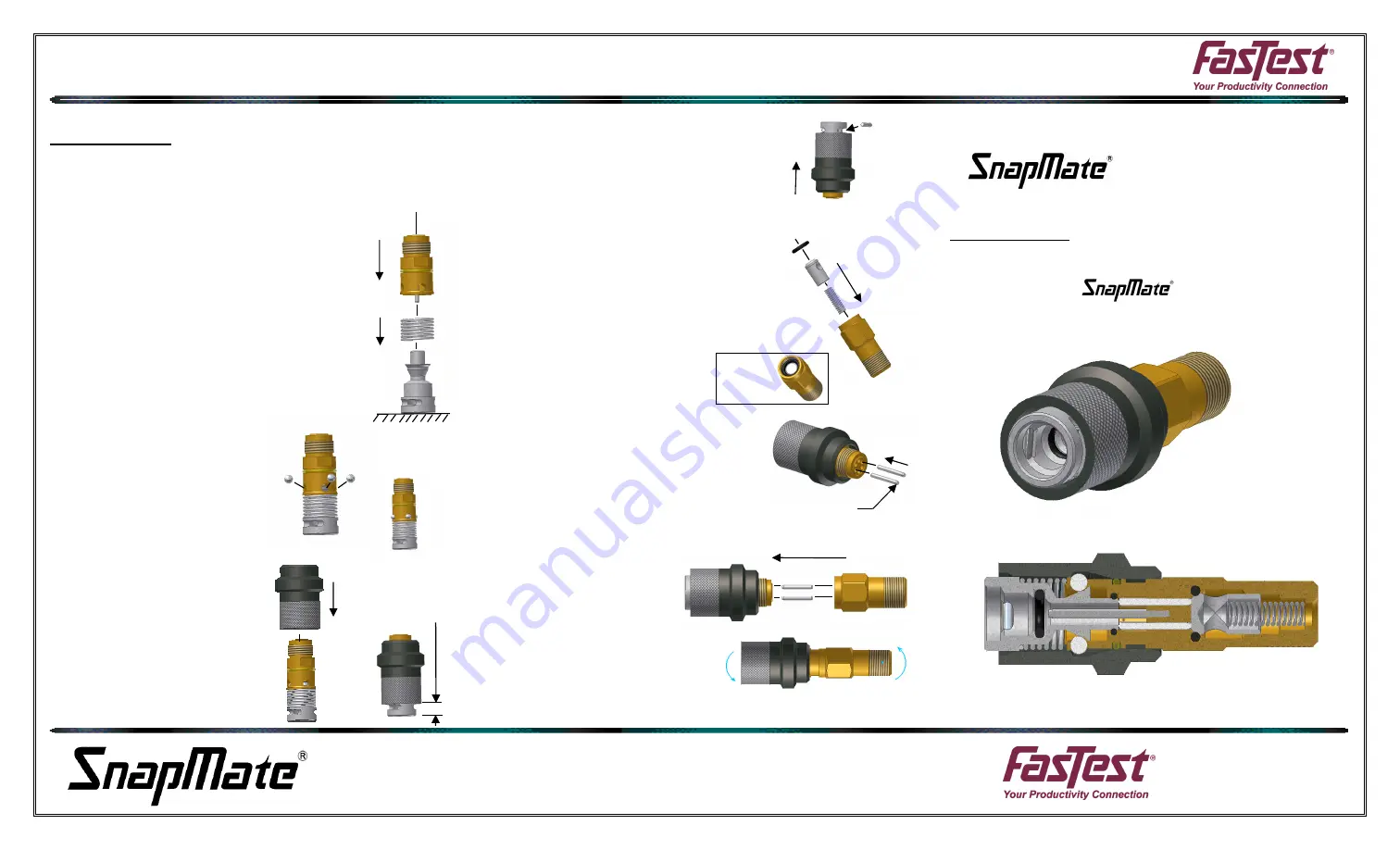

(1)ADD

SPRING

(2)ADD

BODY

SLIDE

SLEEVE

STEP

COMPLETE

LEAVE ROOM

FOR LATCH

PINS

ASSEMBLE IN

ORDER SHOWN

TAPERED

END

TORQUE TO

10FT-LBS

SLIDE

SLEEVE

INSERT

PINS

REASSEMBLE:

Use all the new seals provided and lubricate lightly with an oil

compatible with your system / process during assembly. Re-

place pins with new pins as provided in the rebuild kit.

1) Place piston with end facing down on

solid surface and add the piston spring.

2) With the piston seal and sleeve o-ring

already replaced, slide the front body

over the back of the piston. This will re-

quire some force but if properly lubricat-

ed, it will slide over without damaging

the seal.

3) Continue to compress the

front body over the piston and

add the 4 balls into their re-

spective holes. Do not re-

lease the pressure until step 4

is complete.

4) Slide the sleeve over the

compressed assembly up to

the grip pin slots.

5) Flip the connector over and inset the

latch pins. Slide the sleeve over the

pins to retain.

6) Insert the spring and poppet into the

back body.

7) Lightly lubricate the poppet seal and in-

sert into the back body above the pop-

pet.

8) Insert the poppet pins into the back of

the front body. Make sure the poppet

pins have the tapered side toward the

poppet. Pins are not required to be

placed in any specific holes but they

must be placed opposing.

9) Use a drop of LocTite

242

on

the

body

threads and assemble

the two body halves.

Tighten threads to 10ft-

lbs.

SCPR50 Rebuild Kit

Valved In-Line

DESCRIPTION:

Rebuild kit for internally valved,

in-line with pin grip.

INSERT

PINS

STEP 6&7

SUB-ASSEMBLY