7

Table 1

Part No.

Grade

Finish

Size

18632X1 (055)

3F

Roughing

1/2 oz. tube

18633X1 (075)

38-500

Medium

1/2 oz. tube

18634X1 (105)

38-1200

Final

1/2 oz. tube

7. Cleaning & Lapping

Each part should receive a visual examination for signs of wear and

corrosion. Parts that show signs of excessive corrosion or wear should be

replaced with genuine Farris Factory supplied parts.

All parts should be thoroughly cleaned with an appropriate solvent.

Particular attention should be paid to guiding surfaces such as stems,

stem retainers, and guides. These surfaces should be free of corrosion or

signs of pitting.

Stems should be examined to determine if they are straight. The nozzle

(body on screwed valves) should be examined to ensure there is no foreign

matter that could restrict the valve’s flow. All threads should be examined

to make sure there is no damage that will interfere with assembly or

operation of the valve.

Flange facings should be examined for signs of damage that would inhibit

proper sealing. Gaskets and soft goods, such as O ring seals should always

be replaced. Never perform a repair using the old gaskets and O rings.

To ensure proper valve performance, the nozzle (seat) and disc must be

lapped flat to a mirror finish. This can be accomplished using cast iron

lapping blocks, Pyrex lapping glasses or on a lapping machine. These

devices are used in conjunction with special lapping compounds (See

Table 1).

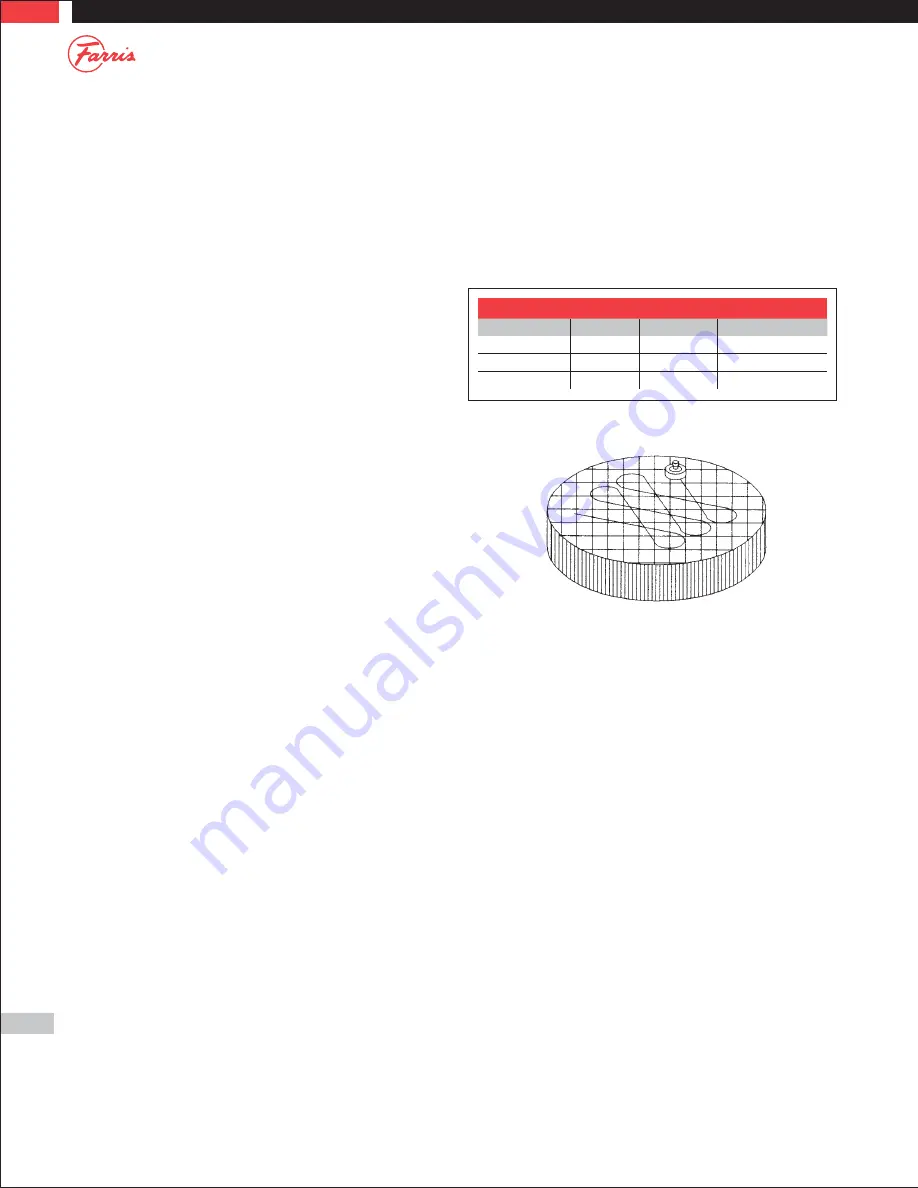

Lapping Procedure:

1. Use a cast iron lapping block or Pyrex lapping glass that is perfectly flat.

2. Select the appropriate compound from Table 1 and place a small

amount on the lap. When lapping the disc, use a light figure eight

motion (Figure 5). Frequently lift the disc away from the glass or block

to get a new bite on the compound.

3. Follow the same procedure when lapping nozzles or screwed valve

bodies except that the lapping block should be placed on the nozzle.

Use the same figure eight motion, frequently lifting the glass or block to

get a new bite on the compound.

4. Lap to a mirror finish. When done, make sure all compound is

completely removed from the parts using a suitable solvent. Handle the

parts with care to avoid scratching the seating surfaces.

Figure 5