Basic Training Workbook

Version 1.5 - August 2007

60

Chapter 4: Basic Part Measurements (Metrology Mode)

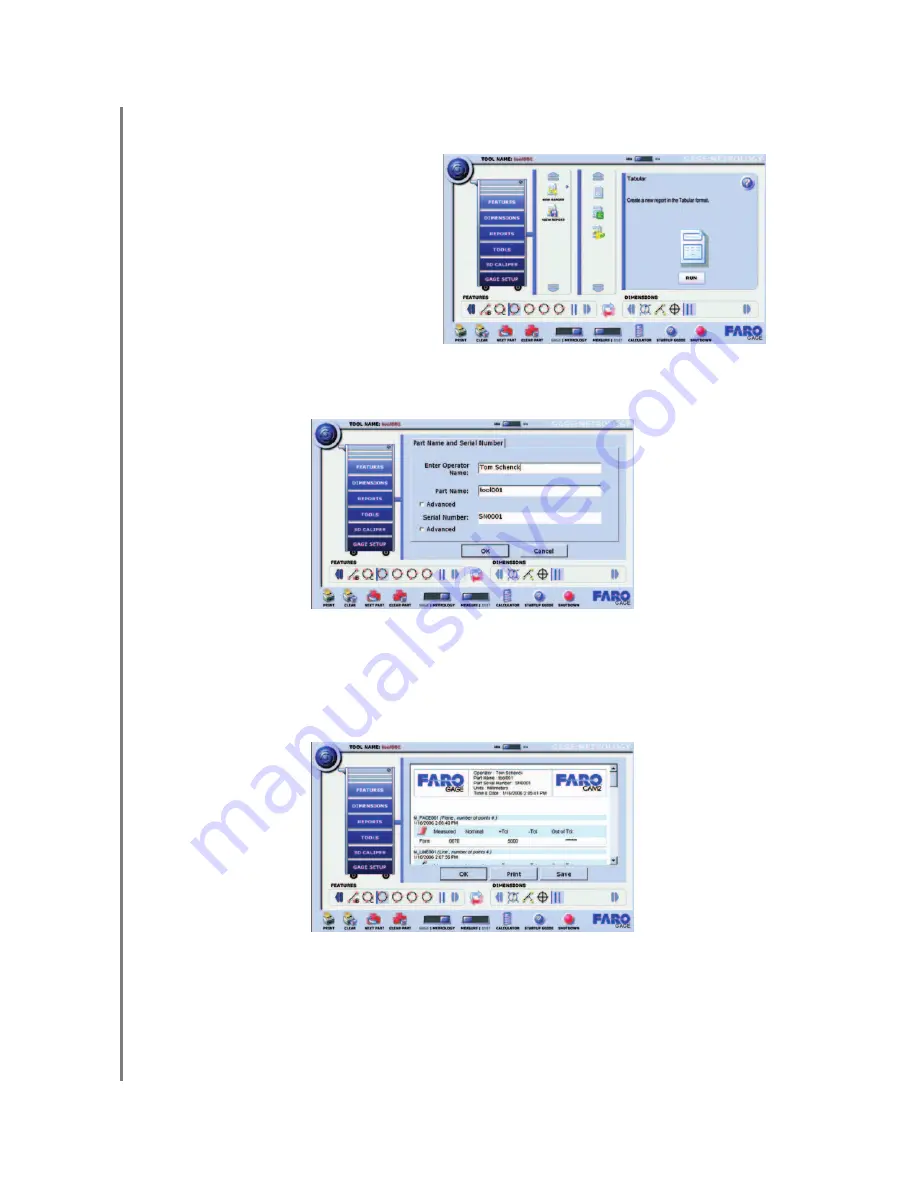

Use the Tabular command to create a report of the features and dimensions on your part.

5

Type your name, the part name, and the serial number, or use the defaults.

N

OTE

:

Select the ADVANCED check box to choose from existing part names or serial

numbers.

6

Select OK to generate the report preview.

•

Select OK to exit the command.

•

Select PRINT to send the report to any printer connected to your computer.

•

Select SAVE to create a report file on your computer. You may view and print this

file later using the View Report command.

1

Select the REPORTS drawer in

the Toolbox.

2

Select the NEW REPORT

group.

3

Select the Tabular command.

4

Select the RUN button.