6

TROUBLE

CHECKOUT PROCEDURE & INFORMATION

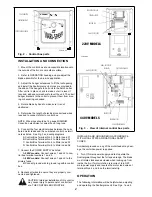

2. OVERLOAD CONDITION - Turn OFF power at disconnect and lock it OFF; check for

freedom of rotation of thrower blade.

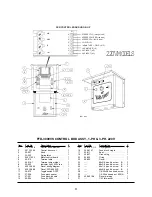

3. FAULTY SPEED CONTROL (POTENTIOMETER) - Move speed control knob to (0)

dial setting. Connect DC voltmeter between armature terminals A and -A on

SCR control. Turn speed control knob CW; needle on voltmeter should increase and be

at 180 VDC when speed control knob reaches (100) dial setting. If voltmeter does not

increase at a rate in relation to the turning of the speed control knob, the potentiometer

may be faulty and the SCR control will need to be replaced. In some cases, just the

potentiometer can be replaced if it is separate from rest of SCR control.

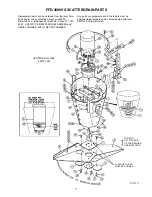

4. LOOSE WIRING CONNECTIONS - Check that all wire connections are secure in vari-

speed control box and motor connection box on outside of Scattergrain cone.

5. WORN BRUSHES IN MOTOR - Have them replaced by a qualified serviceman or

motor repair shop.

6. DEFECTIVE MOTOR - Remove motor and have it checked by a qualified serviceman

or motor repair shop.

Motor runs at high

speed and cannot be

controlled.

1. SHORTED POWER SEMI-CONDUCTORS - Replace SCR control.

2. FAULTY SPEED CONTROL (POTENTIOMETER) - Move speed control knob to (0)

dial setting. Connect DC voltmeter between armature terminals A and -A on

SCR control. Turn speed control knob CW; needle on voltmeter should increase and be

at 180 VDC when speed control knob reaches (100) dial setting. If voltmeter does not

increase at a rate in relation to the turning of the speed control knob, the potentiometer

may be faulty and the SCR control will need to be replaced. In some cases, just the

potentiometer can be replaced if it is separate from rest of SCR control.

Repeated fuse blowing

1. LOW VOLTAGE - Check input voltage between terminals 1 and 2 on terminal strip in

Vari-speed control box; voltage should not be below 218 VAC; increase voltage to 230

VAC.

2. OVERLOAD CONDITION - Turn OFF power at disconnect and lock it OFF; check for

freedom of rotation of thrower blade.

3. LOOSE WIRING CONNECTIONS - Check that all wire connections are secure in vari-

speed control box and motor connection box on outside of Scattergrain cone.

4. WORN BRUSHES IN MOTOR - Have them replaced by a qualified serviceman or

motor repair shop.

5. DEFECTIVE MOTOR BEARING - Have them checked and replaced by a qualified ser-

viceman or motor repair shop.

6. DEFECTIVE ELECTRICAL COMPONENTS - Replace SCR control.

7. DEFECTIVE MOTOR - Remove motor and have it checked by a qualified serviceman

or motor repair shop.

1. LOW VOLTAGE - Check input voltage between terminals 1 and 2 on terminal strip in

Vari-speed control box; voltage should not be below 218 VAC; increase voltage to 230

VAC.

Motor stalls or runs at

very low speed with

speed control turned on

to full CW (100) dial set-

ting.