RESTRICTED USE ONLY

Fargo Electronics, Inc.

HDP600 High Definition Card Printer/Encoder User Guide (Rev. 2.3)

4-14

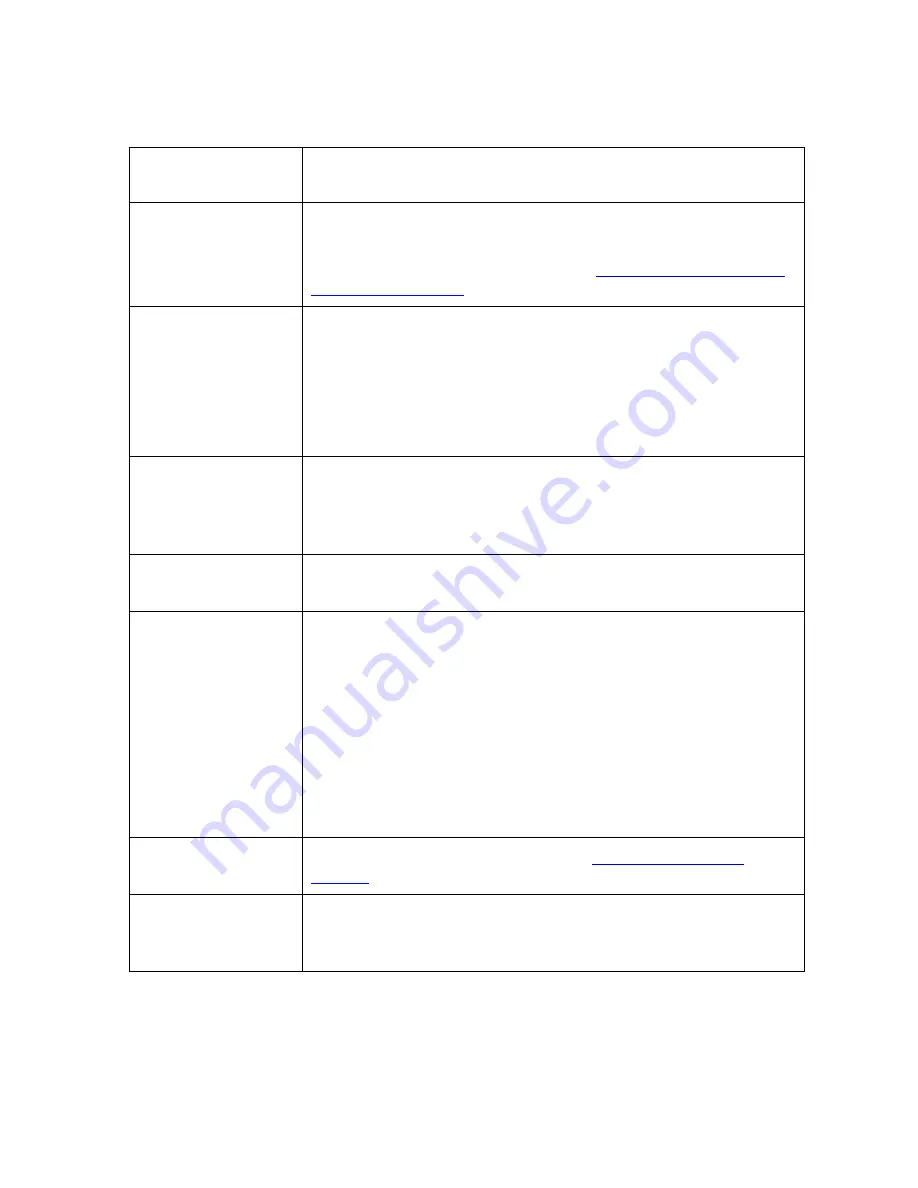

General Troubleshooting Guide (continued)

Problem

Possible Solution

Input Roller

continually spins on

power up

Verify the cable (D840687) is plugged into the Sensor (840176)

and the Circuit Board (J58).

Replace the cable (D840687). See the

Removing the PCB Board

Assembly (A000300)

procedure.

Card Jam during

printing 60 mil cards

Check the peel off bar height with fixture TL 1733.

Verify the TOF and print offset are correct.

Replace the Stepper Motor Cable (D860120).

Verify the Lamination Roller (D880146) spins freely.

Warning: The Lamination Roller may be extremely hot.

Printer will queue up

Ribbon and film but

will not print

In the diagnostic mode of the LCD, check the Platen Roller

(D860022) to verify that it is spinning clockwise when pressing

FORWARE. If the Motor is spinning counter-clockwise, replace

the Stepper Motor Cable (D860120).

Dash Lines on Image Check the Lamination Roller (D880146) or Platen Roller

(D860022) for cuts or nicks.

Film Sensor Error

Verify the Film Sensors (J35 and J36) have not been switched.

Verify the Take-up Motor turns without delay when Lamination

begins. Increase the transfer tension if the Motor delays.

Verify that the washers (760386) are between the e-clip and

springs on the spring loaded film and Ribbon hubs.

Verify the film is not telescoped on the roll with fixture TL1574.

Verify the Platen Roller stepper Motor cable (D860120) is wired

correctly and is connected to the Motor (E000062) and the circuit

Board (A000300) J32.

Ribbon Sticking to

the Film

Increase the Ribbon Tension. See the

Adjusting the Ribbon

Tension

procedure.

Film is only printing

on the back half of

the card

Check to see if the Lamination Lift Motor (D840980) is rotating in

the correct direction.

Continued on the next page