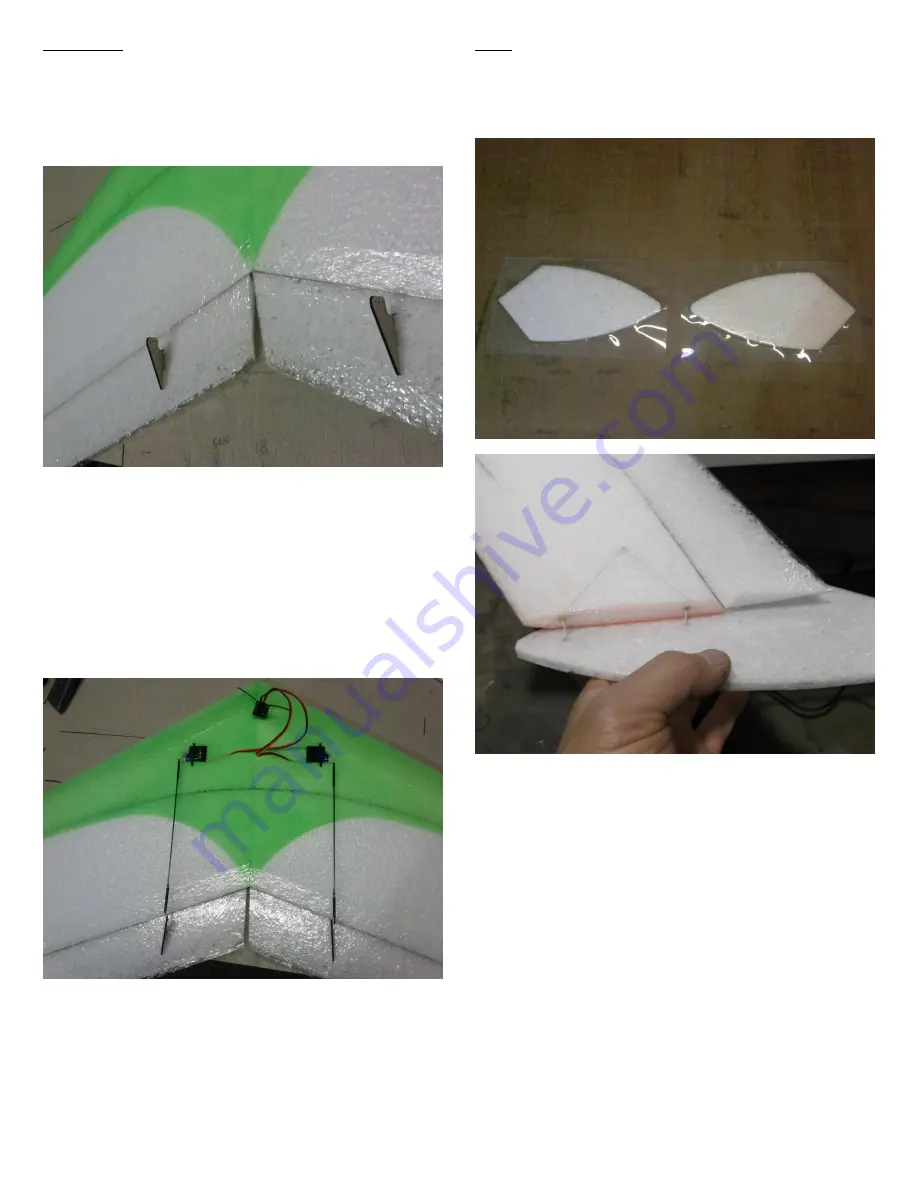

Push rods:

Cut a slit in the elevons for the control horns. The control

horns are located so the push rod holes are 3/16”” behind

the hinge line. The elevon should be able to rotate up a

little past 90 deg before the control horn hits the wing.

Glue the control horns in place. I like using Hot Glue for

this as it is stiffer than Foam-Tac.

Cut 4 pieces of the 1/32” metal wire 1-1/2” long and 4

pieces of heat shrink tube 1” long. Cut the 1.5mm carbon

rod to length ¼” short of the hole to hole distance from

Control horn to servo arm with the servo arm in the

neutral, tilted back position. Bend a z-bend on one end of

each of the metal wires. Insert the metal wire and carbon

rod into the heat shrink as shown. Apply a drop of CA to

the end of the shrink tube and then shrink the tube. Use a

piece of cardboard covered with aluminum foil to keep

from melting the foam.

Fins:

Cover the tip fins with laminating film. Glue them to the

tip or use Leadfeathers bungy method described on the

RcGroups thread.

A final CG check can be done. You can set it between 9-

1/4 and 9-3/4” from the nose depending on how you like

the feel. The further back the CG is the better it will flip.

Have fun and be sure to post pictures and comments on

the RcGroups thread.

Thank You,

Mike & Niki Bailey

Fancy Foam Models

3