10

SECTION 6 -

OPERATING INSTRUCTIONS

The fryers are of single pan type and the following units

are covered by this manual.

G401F - Manual control model with built-in filtration.

G402F - Four product key electronic control model

with built-in filtration.

USE OF OILS/SHORTENING/SOLIDS

(COOKING MEDIUM)

As these are highly flammable when in their liquid state,

caution should always be taken when using cooking

medium.

Recommendation

PPE (Personal Protective Equipment) should be used

when cleaning or handling medium within this fryer.

Medium should not be overheated as this will increase

the risk of fire.

Note: Fryer is fitted with a thermal safety device. This will

stop heating of medium if it becomes overheated.

This appliance will always fail safe.

Note: NEVER leave a working unit unattended.

Medium must always be maintained within fry pot.

Cold Medium - when filling with cold medium (see Figure

5), DO NOT FILL MEDIUM PAST -MIN- LEVEL MARK

(Maximum cold fill mark) also, for Solid Medium -

See Section 9.

-MIN- Level Mark: Medium should NEVER be allowed to

drop below this mark. Should this occur, top up

immediately or switch fryer OFF.

Hot Medium and

Topping Up Medium

DO NOT FILL MEDIUM

PAST -MAX- LEVEL MARK

(Maximum Hot Fill Mark).

(See Figure 5).

Figure 5

CAUTION: SUITABLE PROTECTIVE CLOTHING

MUST BE WORN when topping up whilst fat in fryer

is hot.

Medium and Foodstuffs

As foodstuffs increase volume during cooking - follow

these rules:

DO NOT ADD WATER TO FRYING MEDIUM AT ANY

TIME!

WARNING

No attempt must be made to operate this appliance

during a power supply failure.

Please ensure that any plastic coated items are removed

prior to use. Before operation, pan requires to be

thoroughly cleaned and dried.

Discolouration of heated parts is caused by factory

testing to ensure unit is satisfactory. It will not affect

quality or performance.

All Models

A neon indicator is incorporated to indicate flame failure

when illuminated.

An electronic thermostat with temperature probe is fitted

to automatically control oil temperature. The burner is

protected by an electronic flame sensor device.

An additional temperature limit thermostat is also fitted,

independent of main thermostat.

Operating thermostat failure could allow oil temperature

to exceed the legislated maximum safe temperature

(230

⁰

C). In such condition, the limit thermostat will

activate and cut power to controller and it will also stop

the flow of gas to burner.

To find location of re-set limit thermostat, refer to

Figure 4 on Page 6 of this manual.

Limit Thermostat Reset

a) Turn burner and temperature controls ON/OFF switch

to OFF position.

b) Allow oil to cool below 180

⁰

C.

c) Unscrew black protective cap from limit thermostat

reset button, button is located behind cabinet door at

upper RH below fascia panel.

d) Reset red button on limit thermostat with a pen or

similar item.

e) Turn burner and temperature controls ON/OFF switch

to ON position.

f) Reselect temperature.

g) If limit thermostat reactivates an investigation to

determine the reason must be carried out by a

qualified technician.

6.1 APPLIANCE CONTROLS

Refer to Sections 2.4.1, 2.4.2 and 2.4.3 for controls

layout and description.

Summary of Contents for G402F

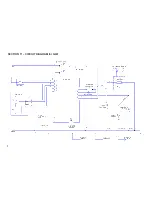

Page 16: ...SECTION 11 WIRING DIAGRAM for G401 16...

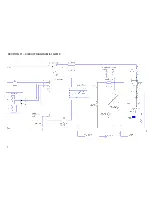

Page 17: ...SECTION 11 WIRING DIAGRAM for G401F 17...

Page 18: ...SECTION 11 WIRING DIAGRAM for G402 18...

Page 19: ...SECTION 11 WIRING DIAGRAM for G402F 19...

Page 20: ...SECTION 11 CIRCUIT DIAGRAM for G401 20...

Page 21: ...SECTION 11 CIRCUIT DIAGRAM for G401F 21...