H8500A Hydraulic Impact Wrench, Drill and Screwdriver

Greenlee / A Textron Company

4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

6

Inspection

Clean all parts with an appropriate cleaning solution

and dry them thoroughly. Inspect each component as

described in this section. Replace any component that

shows wear or damage.

1. Motor Cap (47) with Bearings (48): Insert shaft

into bearings. Spin shaft. If the shaft does not spin

smoothly, replace the entire assembly with bearings

already pressed in.

2. Handle (1) with Bearings (3): Insert shaft into bear-

ings. Spin shaft. If the shaft does not spin smoothly,

replace the entire assembly with bearings already

pressed in.

3. Races (36, 38) and Steel Balls (37): Insert all 18

balls (37) into the outer race (36). Install the inner

race (38) over the steel balls. Slide the drive shaft

(39) into the races and spin the shaft. If the shaft

does not spin smoothly, replace the inner race (38)

and steel balls (37). If the outer race (36) is worn or

damaged, replace the entire handle assembly with

the outer race already pressed in.

4. Gear with Internal Bearings (52): Insert a dowel

pin (54) into the bearing. While holding the dowel

between a thumb and forefinger, roll the gear in the

palm of your other hand. Repeat for the other gear.

If either gear does not spin smoothly, replace both

gears with bearings already pressed in.

5. Inspect all other disassembled components for

cracks, grooves or nicks.

Assembly

Refer to the Illustration and Parts List for correct

orientation and placement of parts.

Replace any O-rings, V-rings, seals, and gaskets on

parts that have been disassembled. Apply hydraulic

fluid or O-ring lubricant to all O-rings and all metal

surfaces which they must slide over. When installing

an O-ring which must slide over sharp surfaces, use a

rolling motion and be careful not to damage the O-ring.

Wherever the assembly results in metal-to-metal contact,

coat the surfaces with hydraulic fluid or O-ring lubricant.

Some steps of the assembly procedure require a

removable type of thread sealing and locking compound,

such as Loctite

®

242

®

or equivalent. Follow the manu-

facturer’s instructions for curing.

Motor

1. Use an O-ring tool to install the O-ring (2) into the

handle.

2. Lubricate the outer race (36) liberally with grease.

Install the 18 steel balls (37) into the outer race (36).

Install the inner race (38) over the steel balls.

3. Slide the drive shaft with gear (39) into the races

and through the handle.

4. Install the Woodruff key (41) and one gear (40) onto

the drive shaft (39), guiding the keyway in the gear

over the Woodruff key. Fasten the gear to the drive

shaft with the retaining ring (42).

5. Install the drive pin (44) into the idler shaft (43).

Slide the remaining gear (40) onto the idler shaft,

guiding the keyway in the gear over the drive pin.

Install this assembly into the handle (1), meshing

the two gears (40).

6. Install the dowel pins (45) into the handle. Install the

gasket (46).

7. Assemble the motor cap (47) to the handle (1),

aligning the scribe marks.

8. Apply a removable type of thread sealing and

locking compound, such as Loctite 242 or equivalent,

to the eight cap screws (49). Follow the manufactur-

er’s instructions for curing.

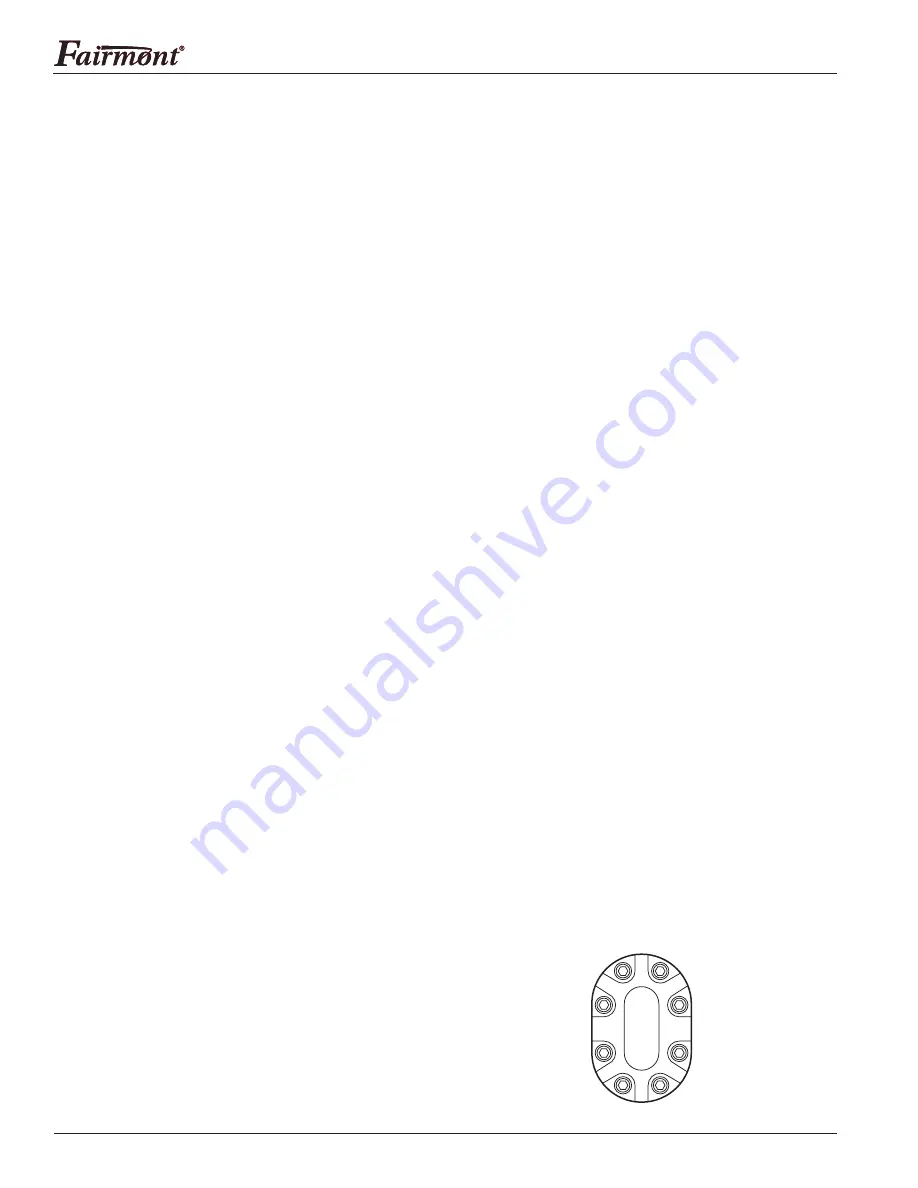

9. Secure the motor cap (47) with the eight cap screws

(49). Using the sequence shown here, torque to

9 newton-meters (80 in-lb).

Torque Sequence

1

3

4

2

5

7

8

6