40i - Installation/Operation - DRO installation - (36/40)

4.6.5.2

Parameters for the threading function

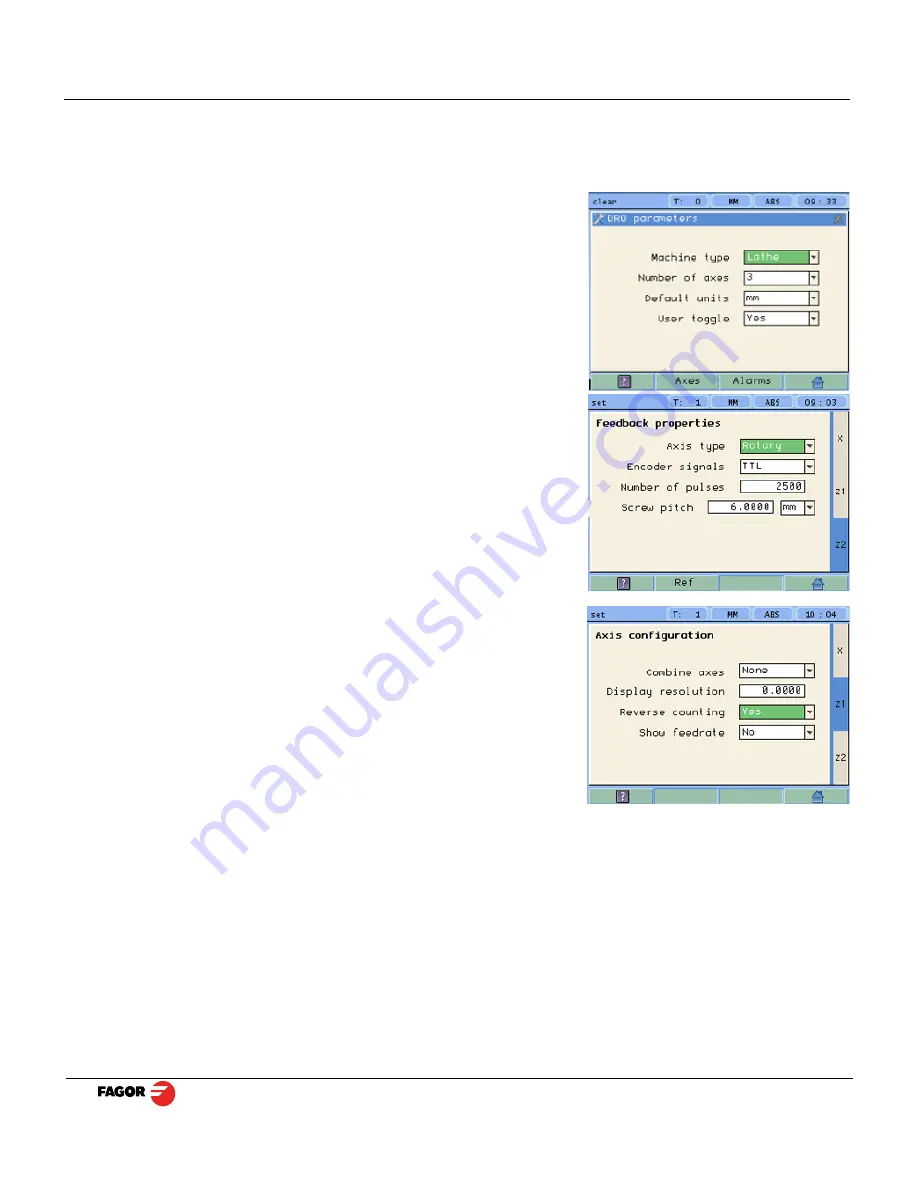

In Feedback properties set Z2 as Rotary axis type (Z2 reads the pulses of the encoder connected to the

leadscrew in the lathe). Then, follow the instructions on the screen to complete the configuration of Z2:

number of pulses of the encoder and the leadscrew pitch of the lathe in millimeters or inches.

Access the DRO, AXIS and FEEDBACK parameters as

described in the previous sections and set them as follows:

Machine type:

Lathe

Number of axes:

3

Default units:

mm or inches.

Type of axis

: Rotary.

Number of pulses

: Depends on encoder.

Pitch

: Depends on leadscrew/ballscrew. In millimeters (mm) or

threads per inch (tpi).

Note

: If the polarity of the Z axis linear encoder needs to be

reversed, follow steps below for Z1.

Change Reverse Counting to Yes.

It will ask you if you want to save parameters. Press Yes.