DC Servo Drive System Manual Ver: 0009

DC - 24/32

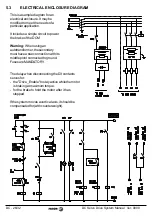

Encoder feedback connection.

The encoder signals must be taken to the ENCODER INPUT of the DCS.

The DCS amplifies these signals and it sends them out through the ENCODER OUTPUT

connector. This serves as position feedback to close the position loop at the CNC.

The encoder must turn with the motor shaft and it must not be installed anywhere else in the

transmission chain. It must output 2000 or more pulses per turn for a good regulation and its

signals must be differential (double ended) 5V.

The encoders installed on Fagor DCM motors appearing in this manual meet these requirements.

On the identity card, put selector J1 in the (bc) position.

Fagor supplies these full connections (cable + connectors), SEC and DCEC.

Tacho feedback connection.

The tacho must turn with the motor shaft and it must not be mounted anywhere else in the

transmission chain.

On the identity card, put selector J1 in the (de) position.

Fagor supplies this full connection (cable + connectors), DCTC.

DC Servodrive

DC Motor

Clockwise Rotation

at Shaft End. CWR.

G

8

9

CONTROL

SIGNALS

CONNECTOR

DC Motor

Top view.

9

T

8

Ready Made Cable

DCTC 2x0.34

Ch.

Ch.

+5V

E

N

CO

DE

R

IN

P

U

T

E

N

CO

DE

R

OU

T

P

U

T

(HD,Sub-D,F15)

1

5

11

15

(HD,Sub-D,M15)

1

5

11

15

(HD,Sub-D,M15)

6

5

4

3

2

1

15

9

*A

B

*B

Z

*Z

0V

A

11

DC Servodrive

DC Motor

Front View

TT

L

E

n

c

o

d

e

r

Ready Made Cable

DCEC 5/10/15/20

9

8

7

6

5

4

3

2

1

6

5

4

3

2

1

7

8

9

ROC 9

Blue

Grey

Green

Brown

Pink

Black

Yellow

Red

1

2

3

4

A

*A

B

*B

5

6

7

8

Z

*Z

11

0 V

(HD, Sub-D, F15)

Ready Made Cable

SEC 1/3/5/10/15/20

1

2

3

4

5

6

7

8

11

(Sub-D, M15)

8

1

15

9

(Sub-D,

F15)

Green

Yellow

Blue

Purple

Grey

Pink

Brown

White

Black

Fa

go

r C

N

C

C

a

b

le 4

x

2x

0,

1

4

+

2

x0

,5

(Length in meters;

including connectors)