Connection diagrams

CON

N

ECTION DIAGRAMS

O

n-th

e-fly

start/d

elta conne

cti

on switch

ing

o

n FM7 spin

dles, E03 &

HS3

seri

es

10.

353

DDS

HARDWARE

Ref.1310

10.17

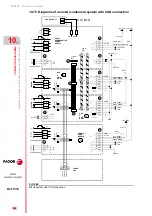

On-the-fly start/delta connection switching on FM7 spindles, E03 & HS3 series

F. H10/30

Diagram of on-the-fly Y/D (start/delta) connection switching for FM7-XXXX-XXX-E03/HS3 motors.

DIGITAL INPUT

X1

X2

GND

I8

I1

N.C.

I2

I3

I4

I5

I6

I7

GND

I16

I9

N.C.

I10

I11

I12

I13

I14

I15

DIGITAL OUTPUT

X1

X2

GND

O8

O1

+24V

O2

O3

O4

O5

O6

O7

GND

O16

O9

+24V.

O10

O11

O12

O13

O14

O15

POWER SUPPLY

FAGOR

DRIVE

SPD

PS-65

A

+ APS

24

(X

2,

X

3

&

X4)

24 V

D

C

, 10 A

PS-25

B

4

(X

4,

X5 & X6

) 24 V

D

C

, 10

A

X

P

S

-X

X (

X

4,

X

5

& X

6

)

24

V D

C

,

8

A

R

P

S-

X

X

(X2)

2

4

V

D

C

, 8 A

24 V (of the FAGOR power voltage)

0 V (of the FAGOR power voltage)

K3

K2

K1

K4

*

GND

CAN L

SHIELD

SHIELD

CAN H

X3

GND

CAN L

SHIELD

SHIELD

CAN H

X2

POWER SUPPLY

4

0

1

F

D

C

B

9

8

7

5

3

ADD MSB

LINE TERM

1

0

12

ADDRESS

RESET

POWER

SYSTEM READY

+5 ERROR

+5 OVER CURRENT

OVER VOLTAGE

+5V

X1

GND IN

CHASIS

GND IN

+24V IN

SYSTEM

READY

K1

K2

A1

A2

Auxiliary relays - KA3, - KA4. e.g. RP821024

Flywheel diodes D3, D4. e.g. 1N4934

24 V

24 V

0 V

OUTPUT 24 V DC

Chassis

THE STAR/DELTA

SWITCH IS MANAGED

BY THE PLC PROGRAM

AT THE 8070 CNC

*

Flywheel diode

1N4934

24 V

0 V

0 V

24 V

A1

A2

0 V

I10

I11

REMOTE I/O

A1

Flywheel diode

1N4934

CANFagor

INTERFACE

0 V

24 V

O11

O10

A2

A1

A2

EXTERNAL AUXILIARY

POWER SUPPLY

- KM2

Star

- KM1

Delta

MPC- 4xN

2

U/U1 V/V1 W/W1

U

V

W

MCP- 4xN

1

MPC- 4xN

1

MPC- 4xN

1

MPC- 4xN

1

M

3

MPC- 4xN

1

X/U2 Y/V2 Z/W2

- KA1

D3

- KA2

D4

- KA4

D3

- KA3

D4

- KM1 contactor: I

(KM1)

> I

N

( )

I

(KM2)

> (1/ ) I

N

( )

3

- KM2 contactor:

U1

W1

U2

W2

V2

V1

U

V

W

U

V

W

V1 W2

V2

W1

U1

U2

STAR connection

DELTA connection

(*)

WARNING.

Never connect an external

auxiliary power supply and a Fagor power

supply at the same time.

Important warnings.

1.

Either an external auxiliary power supply or a FAGOR power supply may be used to supply the 24 V DC.

Never con-

nect both at the same time !

2.

To brake the motor in a controlled way during a power failure, make sure that 24 V DC will be supplied to contactors -

KM1 and - KM2 and relays - KA3 and - KA4. This situation is ensured if you have installed a FAGOR power supply next

to an SPD modular drive. If you have installed an external auxiliary 24 V DC power supply, you must make sure that this

condition is ensured.

3.

When using a compact SCD drive to govern a spindle motor, you must necessarily install an external auxiliary power

supply to provide the 24 V DC. These compact drives do not have an output 24 V DC connector

.

Note.

See these currents in chapter

6. Selection

, of the FM7/FM9 motor manual.

Sizing of motor power cables.

Note.

See the necessary cable section according to table of the chapter

4. Installation

of the FM7/FM9 motor manual.

If you decide to install an external auxiliary power supply, make

sure that in case of a power outage, the 24 V DC are ensured

to brake the motor under control preventing it from braking by

inertia. Ignoring this warning may cause personal injury.

Notes.

The I/O selected in the figure have been chosen arbitrarily. In general any Ixx and Oxx may be used always matching

the ones used in the PLC.

It is very common to choose I1 and O1 for the external emergency. Therefore, we suggest not to use them for this appli-

cation. If they are going to be used, make sure that they have not been set to be used as emergency input and output.

Sizing of - KM1 and - KM2 power contactors.

MPC- 4xN

1

N

1

: section supporting I

N

( )

MPC- 4xN

2

N

2

: section supporting I

N

( )

WARNING.

Summary of Contents for APS-24

Page 1: ...DRIVE DDS Hardware manual Ref 1310...

Page 6: ...I 6 DDS HARDWARE Ref 1310...

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 16: ...16 Ref 1310 DDS HARDWARE...

Page 30: ...1 DESCRIPTION 30 Description DDS HARDWARE Ref 1310...

Page 94: ...2 POWER SUPPLIES 94 Power supplies DDS HARDWARE Ref 1310...

Page 188: ...3 DRIVE MODULES 188 Drive modules DDS HARDWARE Ref 1310...

Page 204: ...4 AUXILIARY MODULES 204 Auxiliary modules DDS HARDWARE Ref 1310...

Page 232: ...SELECTING CRITERIA 5 232 Selection criteria DDS HARDWARE Ref 1310...

Page 266: ...7 CABLES 266 Cables DDS HARDWARE Ref 1310...

Page 312: ...8 INSTALLATION 312 Installation DDS HARDWARE Ref 1310...

Page 326: ...9 FUNCTIONAL SAFETY 326 Functional safety DDS HARDWARE Ref 1310...

Page 354: ...10 CONNECTION DIAGRAMS 354 Connection diagrams DDS HARDWARE Ref 1310...

Page 378: ...12 SALES REFERENCES 378 Sales references DDS HARDWARE Ref 1310...

Page 384: ...13 COMPATIBILITY 384 Compatibility DDS HARDWARE Ref 1310...

Page 385: ......