·432·

Programming manual

CNC 8055

CNC 8055i

15.

COORDIN

A

TE TR

ANSFORMATION

·M· & ·EN· M

ODELS

S

OFT

: V02.2

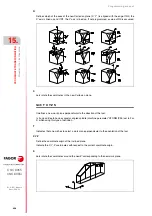

X

Mo

vement in an incl

ined

p

lan

e

15.1.4

Considerations about the G49 function

G49 cannot be programmed in the following instances:

• At the GP model CNC

• From the PLC channel (although it can be programmed from the user channel).

• Within a profile definition for pockets or other cycles.

In order to work with coordinate transformation (G49), the X, Y, Z axes must be defined, they must

form the active trihedron and be linear. The X, Y and Z axes may have GANTRY axes, coupled or

synchronized via PLC, associated with them.

When working with coordinate transformation and performing rigid tapping in inclined planes, all

axes gains (not only for the Z axis) must be adjusted by using the second gains and accelerations.

The parameters associated with G49 are optional. When programming G49 without parameters,

the active coordinate transformation is canceled.

G49 is modal and no more G codes may be programmed alone in the block.

Coordinate transformation is kept active even after turning the CNC off and back on.

To cancel it, program the following:

G49 E1

it cancels it, but it keeps the part zero defined in the transformation.

G49 E0 ó G49

It cancels it and it recovers the part zero that was active before the G49

was activated.

G74

It cancels it, it activates the home search and recovers the part zero that

was active before the G49 was activated.

Zero offsets G54-G59, pattern rotation (G73) and presets (G92, G93) are possible while coordinate

transformation is active.

But the following cannot be done:

• Program a new coordinate transformation without previously canceling the previous one.

• Probing (G75).

• Movement against hardstop (G52).

Summary of Contents for 8055 EN

Page 1: ...CNC 8055 M EN Programming manual Ref 1711 Soft V02 2x...

Page 8: ...8 Programming manual CNC 8055 CNC 8055i SOFT V02 2X...

Page 12: ...12 CNC 8055 CNC 8055i Declaration of conformity and Warranty conditions...

Page 16: ...16 CNC 8055 CNC 8055i Version history...

Page 22: ...22 CNC 8055 CNC 8055i Returning conditions...

Page 24: ...24 CNC 8055 CNC 8055i Additional notes...

Page 26: ...26 CNC 8055 CNC 8055i Fagor documentation...

Page 448: ......

Page 464: ...464 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code...

Page 466: ...466 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code MC operator panel...

Page 467: ...Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X 467 Key code...

Page 468: ...468 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code...

Page 471: ...Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X 471 Key code 11 LCD Monitor...

Page 472: ...472 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code...

Page 478: ...478 Programming manual CNC 8055 CNC 8055i F M EN MODELS SOFT V02 2X Maintenance...

Page 479: ...Programming manual CNC 8055 CNC 8055i F SOFT V02 2X 479...

Page 480: ...480 Programming manual CNC 8055 CNC 8055i F SOFT V02 2X...

Page 481: ......