14

3. Remove accessory, connect the tool to an air source, then cover the exhaust end with a towel and run tool for 2 to 3

seconds.

To lubricate internal mechanism:

Locate the grease fi tting on the back of the tool (fi g. 5). Inject 4 grams of FACOM

approved impact grease into the fi tting every 3-5 months depending on use.

Use recommended grease gun nozzle tip (fi g. 6) on grease fi tting,

smaller or sharp nozzle will damage grease fi tting ball bearing.

WARNING: Keep out of the reach of children. If air tool oil is ingested, do not

induce vomiting, call a doctor immediately.

WARNING: Any excess oil in the tool is immediately expelled from the exhaust

port. Always direct exhaust port away from people or objects.

NOTE: Check the speed and make a simple check of the vibration level after each

service.

Storage:

The air tool must be lubricated before storing.

Follow the “Lubrication” instruction with exception of step 3.

Always use an air line lubricator with this tool.

Do not over-oil and do not use heavy grade oil as stalling and low performance may result.

PLACING TOOL IN SERVICE

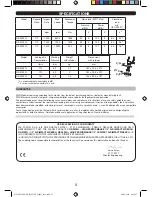

Fig. 5

3.0mm

3.0mm

1.0mm

GREASE NOZZLE

TIP

Fig. 6

EMERGENCY

GATE VALVE

An air fi lter unit should be placed between air compressor and

air lubricator to promote clean air supply to air hammer. Water,

dirt, and scale can damage air hammer.

Fig. 7

NU-NS.3500G-NS.3100G-NS.2500G_0118.indd 14

08/01/2018 08:10:27

Summary of Contents for NS.3500G

Page 66: ...66 15 LED 3 FACOM NU NS 3500G NS 3100G NS 2500G_0118 indd 66 08 01 2018 08 10 39...

Page 101: ...101 NOTA NU NS 3500G NS 3100G NS 2500G_0118 indd 101 08 01 2018 08 10 48...

Page 102: ...102 NOTA NU NS 3500G NS 3100G NS 2500G_0118 indd 102 08 01 2018 08 10 48...

Page 103: ...103 NOTA NU NS 3500G NS 3100G NS 2500G_0118 indd 103 08 01 2018 08 10 48...