Attention:

installations that do not comply with the illustred procedure or or failure to carry out correct maintenance

operations can cause the gate to derail and endanger the safety of persons and propriety

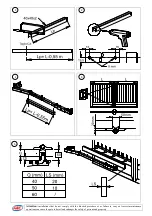

A[m]

L [m]

con/with B=0,07

2

0,94

2,5

1,19

3

1,44

3,5

1,69

4

1,94

4,5

2,19

5

2,44

Esempio misure fuori tabella

Example dimensions not in table

A

=2,8m

B

=0,07m

(min 0,065 m)

C

=0,05m

(da tabella sopra/from above table)

L=

(A-B-C)/2

L

=(2,8-0,07-0,05)/2

L

=2,68/2

L

=1,34 m

Maintenance

To maintain these parts in good and safe working conditions it is necessary to follow these steps:

1.

After gate assembly is completed, perform a few manual opening and closing cycles, make sure there are no loose parts and

periodically lubricate all bearings and junction points.

2.

In case of accidental shock caused by moving vehicles or other external factors, check parts for external damages. In case of

irreparable damage, replace with a new part. Always check the gate by manually opening a few opening opening and closing

cycles. All maintenance procedures must be performed by trained technicians.

3.

If the gate has any difficulty of movement or in presence of abnormal oscillations, the gate must be checked for worn parts

replaced if necessary. Gates working in harsh ambient conditions, such as; hight humidity, salt, acids, dust or temperatures above

120°C will require special attention and frequent maintenance.

4.

For motorized gates, pay special attention when selecting the operatioonal speeed. Soft starts and stops are highly recommended:

•

High speed of operation, and hard starts and stops will be stressful to the system and it may result in loosen nuts, bolts and

irreparable damage.

•

Low operational speeds may cause an elastic effect betwen the leaves

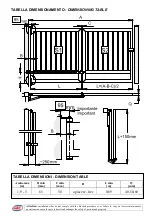

Peso max S2 in funzione della lunghezza L-Max S2 leaf weight according to the L lenght